Handle and vacuum cleaner shell structure and vacuum cleaner

A technology for vacuum cleaners and handles, which is applied in the direction of vacuum cleaners, handles, cleaning equipment, etc. It can solve the problems of handle deformation, overall strength imbalance, damage, etc., and achieve the goal of increasing structural strength, overall strength and local strength balance, and improving overall strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

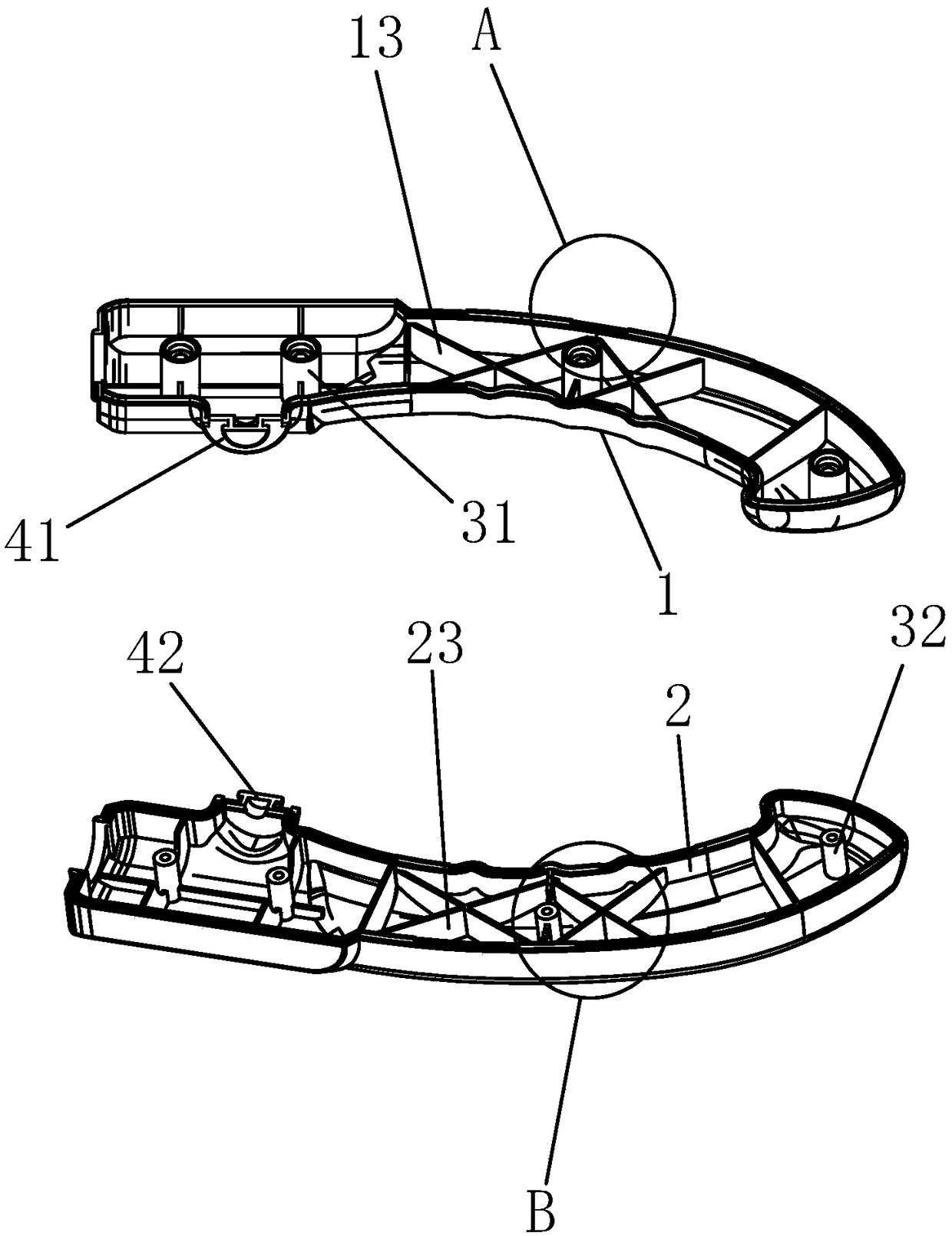

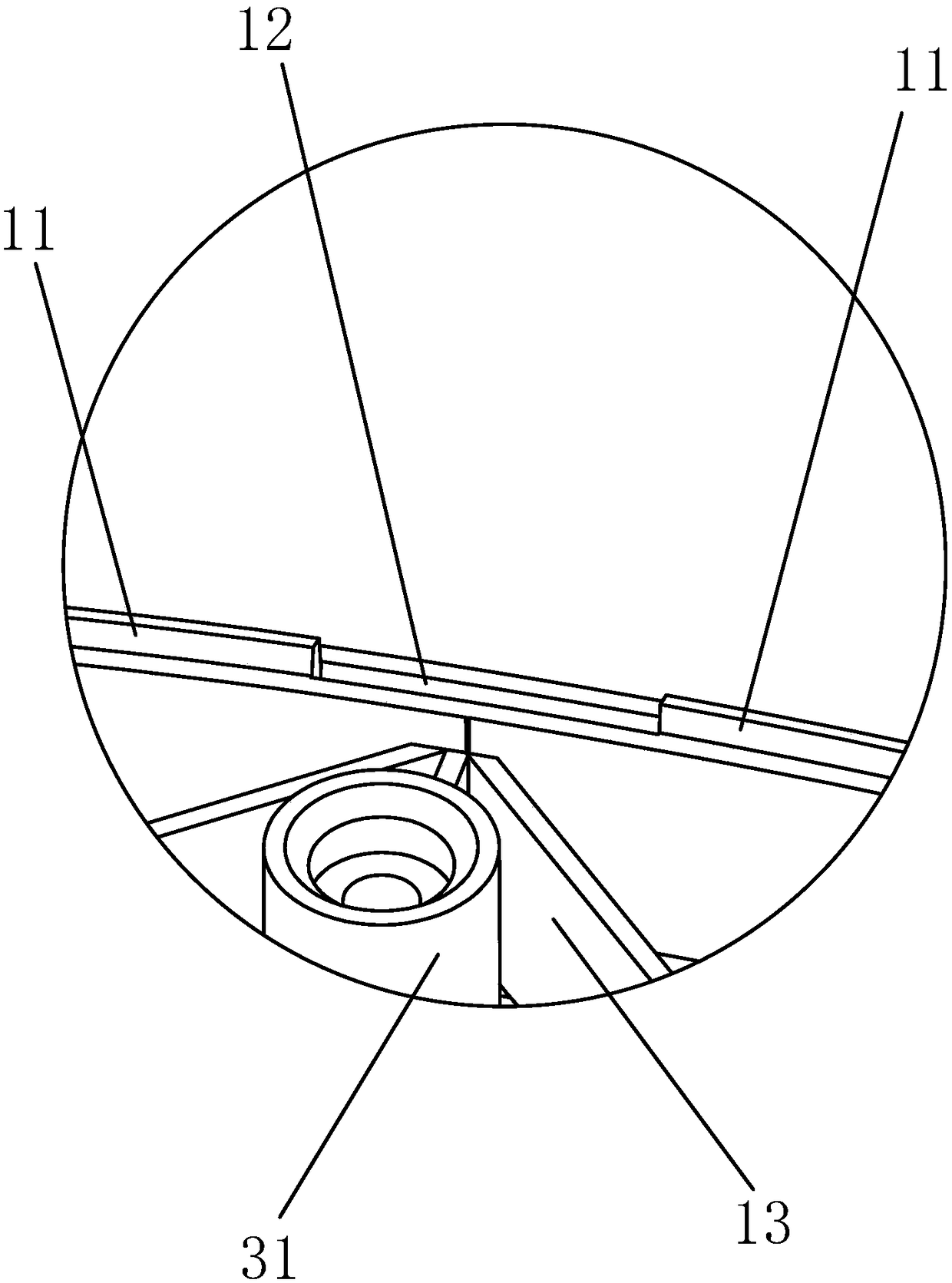

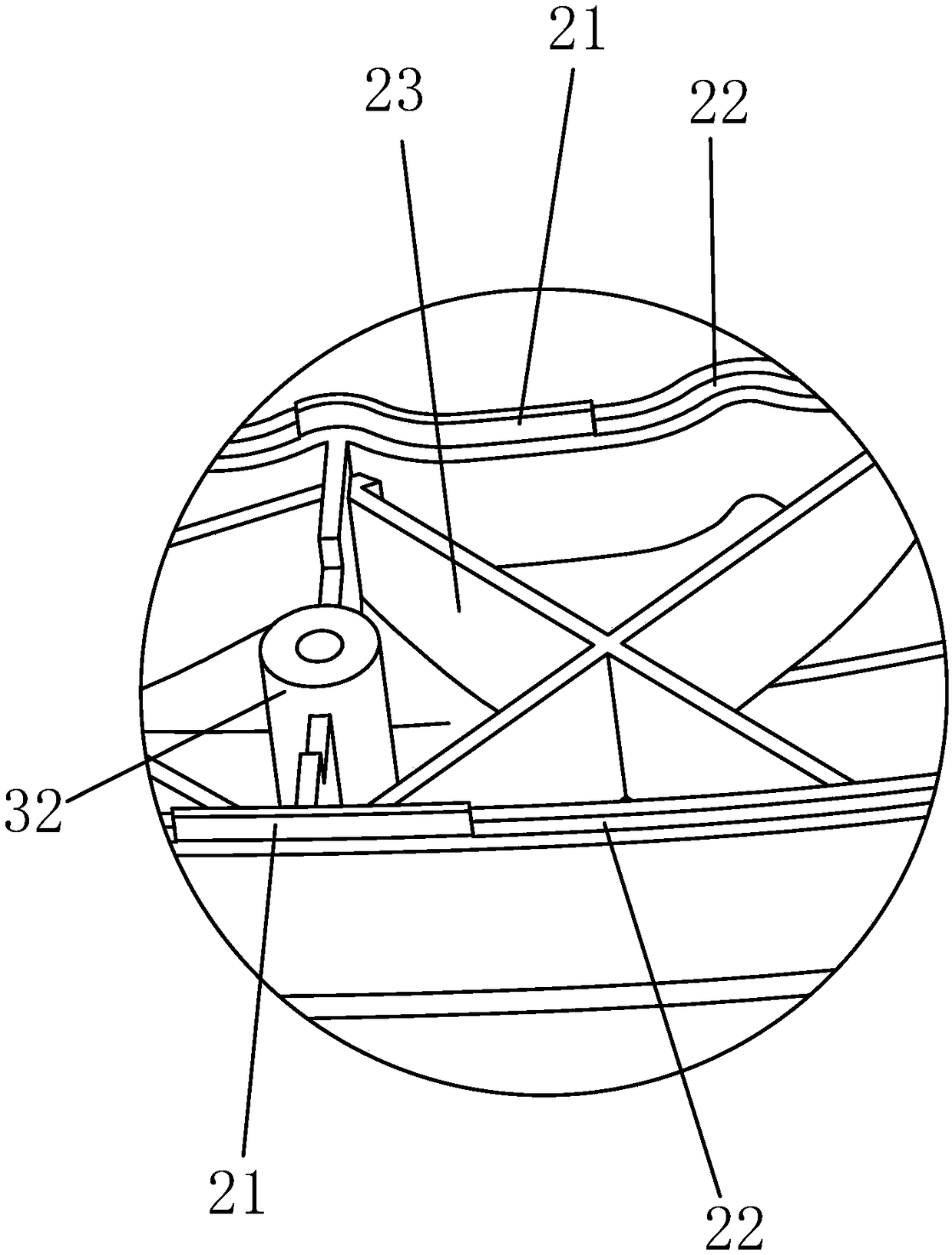

[0030] Embodiment 1: as figure 1 , figure 2 , image 3 as shown in

[0031] a handle, including

[0032] The left half body 1 and the right half body 2 that can be fitted and fixed to each other; the left half body is provided with a left half cavity inside, and the right half body is provided with a right half cavity inside, and the side of the left half body facing the right half body is the left half body. Matching side, the side of the right half facing the left half is the right matching side;

[0033] The left half body is provided with a number of left flanges 11 and a number of left grooves 12, the left flange is arranged on the left matching side, the left groove opens on the left matching side, and the right half is provided with a number of right flanges 21 And several right grooves 22, the right flange is arranged on the right matching side, and the right groove opens on the right matching side;

[0034] The left flange is in one-to-one correspondence with th...

Embodiment 2

[0042] A shell structure of a vacuum cleaner, comprising a left half shell and a right half shell that can fit and fix each other; the side of the left half shell facing the right half shell is the left matching shell surface, and the side of the right half shell facing the left half shell is The right matching shell surface; the left half shell is provided with a number of left shell flanges and a number of left shell grooves, the left shell flange is arranged on the left matching shell surface, the left shell groove opens on the left matching shell surface, and the right half shell The shell is provided with a number of right shell flanges and a number of right shell grooves, the right shell flange is arranged on the right matching shell surface, and the right shell groove opens on the right matching shell surface; the left shell flange and the right shell groove One-to-one correspondence, the right shell flange is in one-to-one correspondence with the left shell groove, the ...

Embodiment 3

[0044] Embodiment 3: based on embodiment 1, as Figure 4 as shown,

[0045] A vacuum cleaner, including a handle as described in Embodiment 1, and also includes a casing 5, a dust cup 51, a handle hard tube 6, a dust mop 7 and a dust collection motor 8, the dust cup is provided with a first The air inlet and the first air outlet, the dust cup is provided with a filter cartridge 511 between the air inlet of the vacuum motor and the first air inlet, the main exhaust port, the first air inlet, and the first air outlet are arranged on the casing , the air inlet of the dust collection motor, the air outlet of the dust collection motor and the main exhaust port are connected in sequence, the mop chamber 7a is provided inside the mop for dust collection, and the bottom suction port 7b connected with the mop chamber is provided on the mop for dust collection and communicated with the mop chamber The upper air outlet pipe 71, the upper air outlet pipe is clamped and communicated with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com