A bearing cylinder and its processing technology

A processing technology and load-bearing cylinder technology, applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the problems of re-decomposition of parts, residual parts of parts, and entry of iron filings, so as to reduce potential safety hazards, prevent pollution, The effect of reduced positioning requirements

Active Publication Date: 2019-10-01

HUNAN SOUTH GENERAL AVIATION ENGINE CO LTD

View PDF6 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

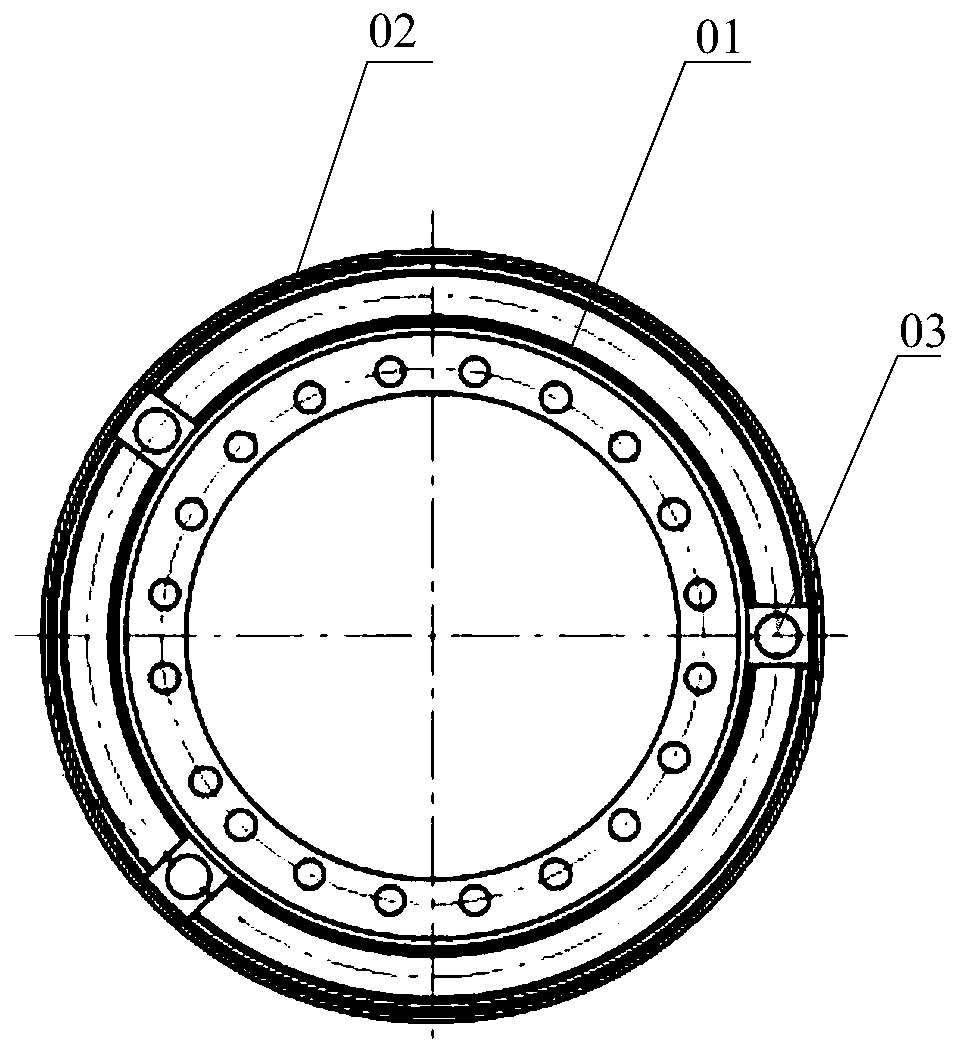

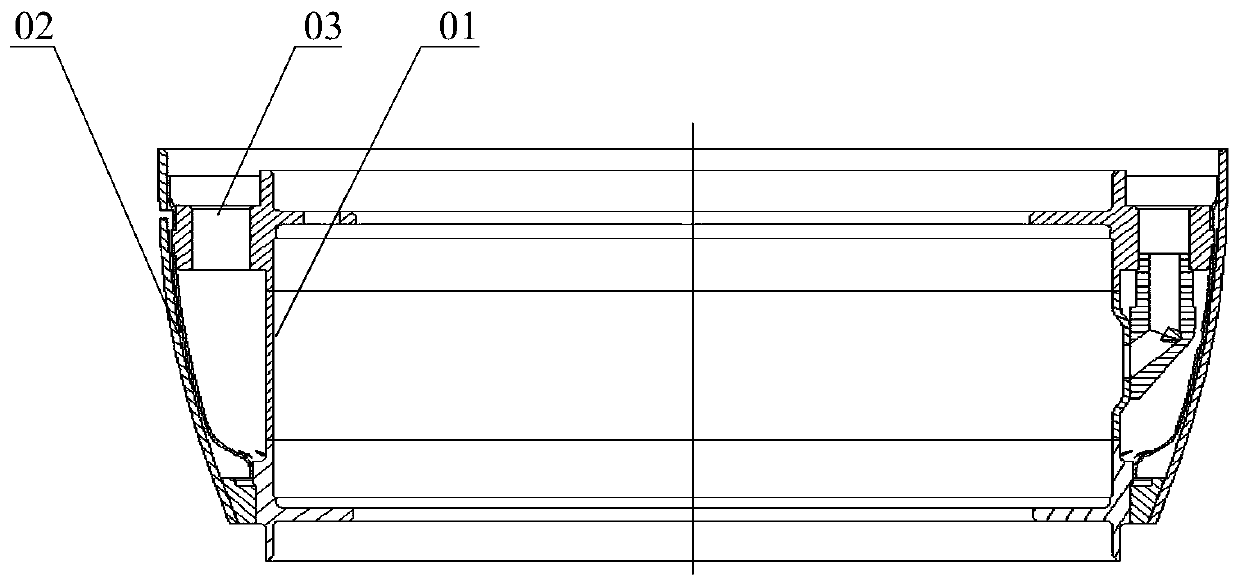

However, it can be seen from the sectional view of the assembly hole of the part (Fig. 2) that the assembly hole 03 is directly connected to the inner cavity of the part, and the assembly hole 03 is processed by digital milling, so it is inevitable that there will be Iron filings will enter the inner cavity of the part along with the coolant, and it is difficult to remove it later, resulting in excess residue inside the part

This type of part is currently a relatively critical part in the development of new engines. It has previously occurred that this type of part has caused the entire part to be re-disassembled due to the existence of excess material in the inner cavity of the part, which has caused major safety hazards during the use of the engine.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

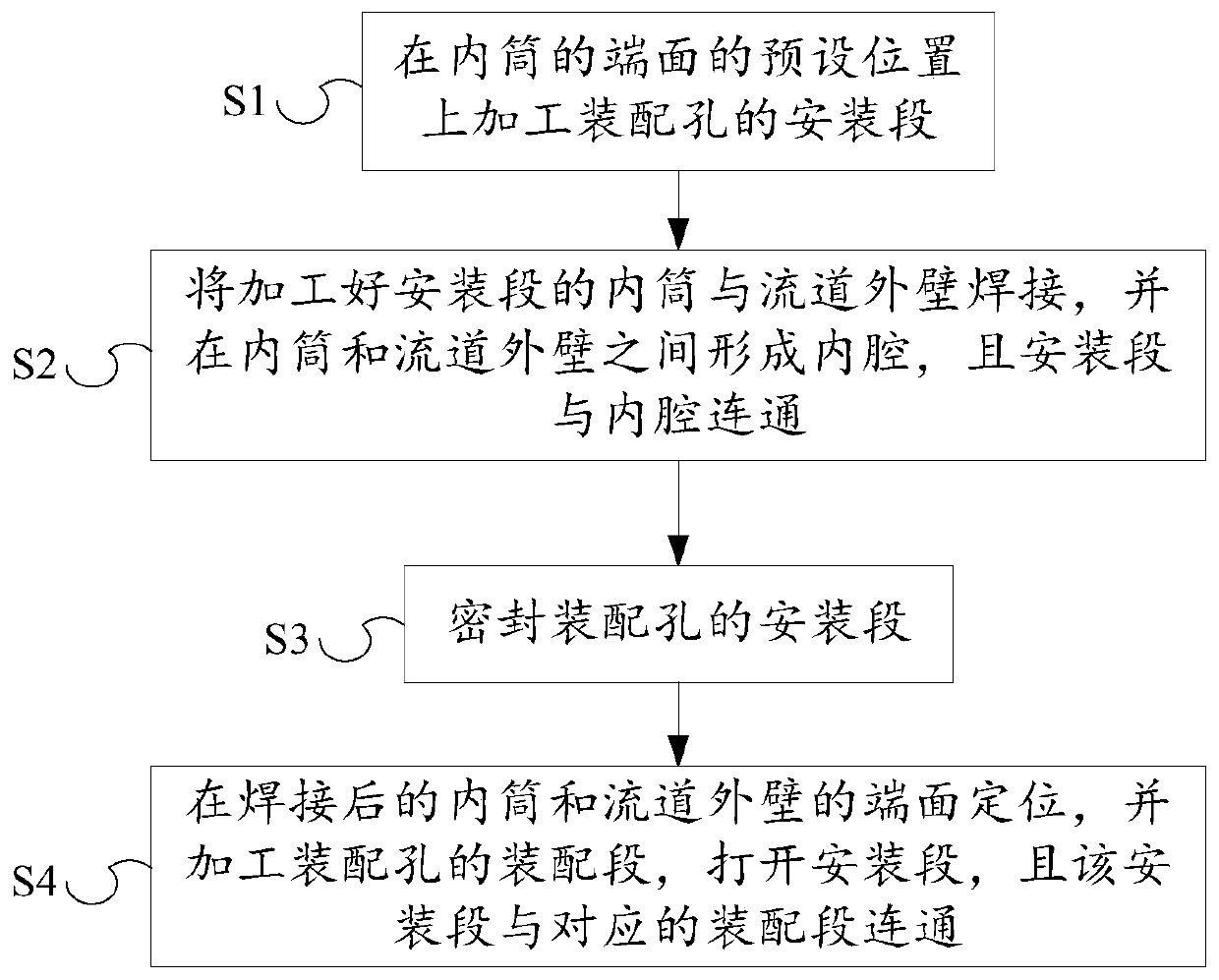

The invention discloses a processing technology of a load-bearing cylinder. During processing, an installation section of an assembly hole is processed on an end face of the inner cylinder, the innercylinder is welded with an outer wall of a runner, the installation section of the assembly hole is sealed, and the assembly section of the assembly hole is processed. As that mount section is in communication with the lumen, Therefore, the positioning requirement of the mounting section is reduced, and when the mounting section is processed, the mounting section can be sealed, thereby blocking the communication between the mounting section and the inner cavity, preventing iron chips and other impurities from falling into the inner cavity, thereby fundamentally preventing the pollution of theinner cavity, and greatly reducing the safety hidden danger existing in the use process of the engine. The invention also discloses a load-bearing cylinder with the above-mentioned processing technology.

Description

technical field The invention relates to the technical field of engines, in particular to a processing technology of a load-bearing cylinder and a load-bearing cylinder adopting the processing technology. Background technique As shown in Figure 1, the load-bearing cylinder parts need to be ventilated, so they are welded through an outer wall of the flow channel 02 and an inner cylinder 01 during design, and an inner cavity is left between the two to ensure that the air flow can pass through smoothly . In the actual processing process, the three assembly holes 03 on the large end face connected to the inner cavity need to be positioned with other components during subsequent assembly, so there is a requirement for position accuracy, so the three assembly holes on the end face 03 must be processed after the outer wall of the flow channel 02 and the inner cylinder 01 are welded. However, it can be seen from the sectional view of the assembly hole of the part (Fig. 2) that th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B23P15/00F02B77/08F02B77/00

Inventor 王道梁微子赵李军谢磊徐宇超杨文彪邹吉亮黄靖姚珍军潘忠

Owner HUNAN SOUTH GENERAL AVIATION ENGINE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com