External thread detection method based on machine vision and real-time detection system

A real-time detection and detection method technology, applied in the direction of instruments, measuring devices, image data processing, etc., can solve the problems of Hough transformation with large calculation amount and small linear parameter range, and achieve reduced calculation amount, good adaptability, and low positioning requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

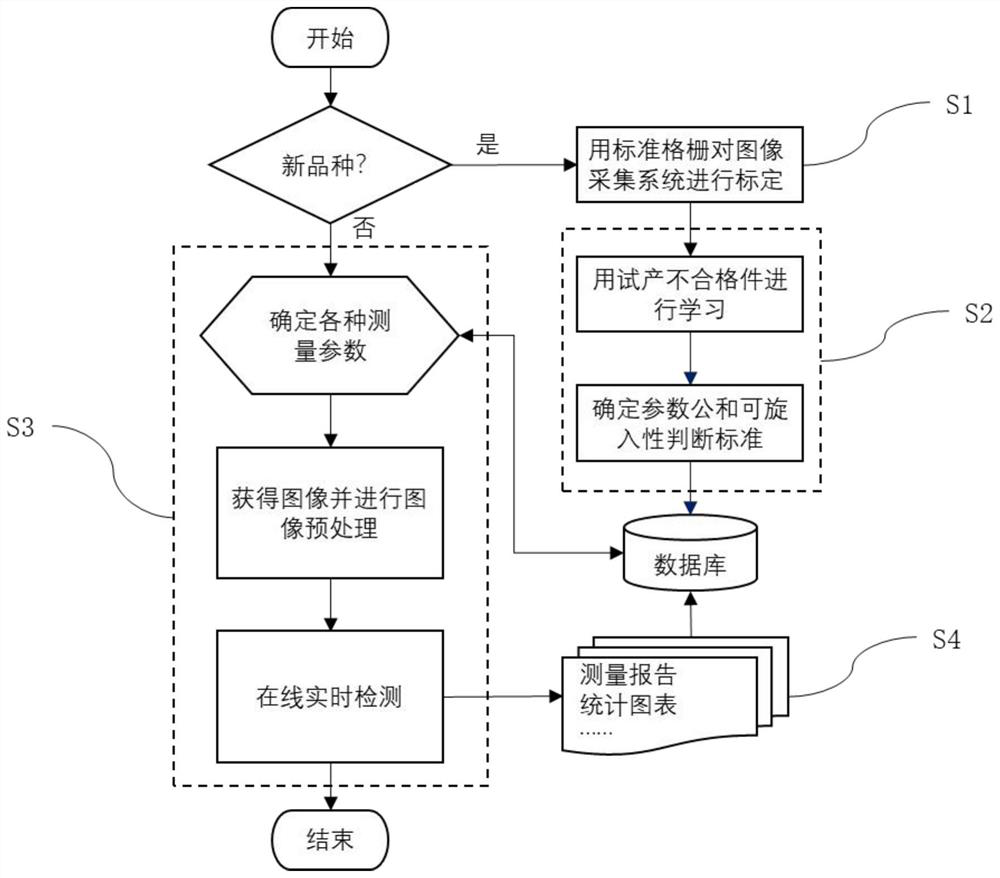

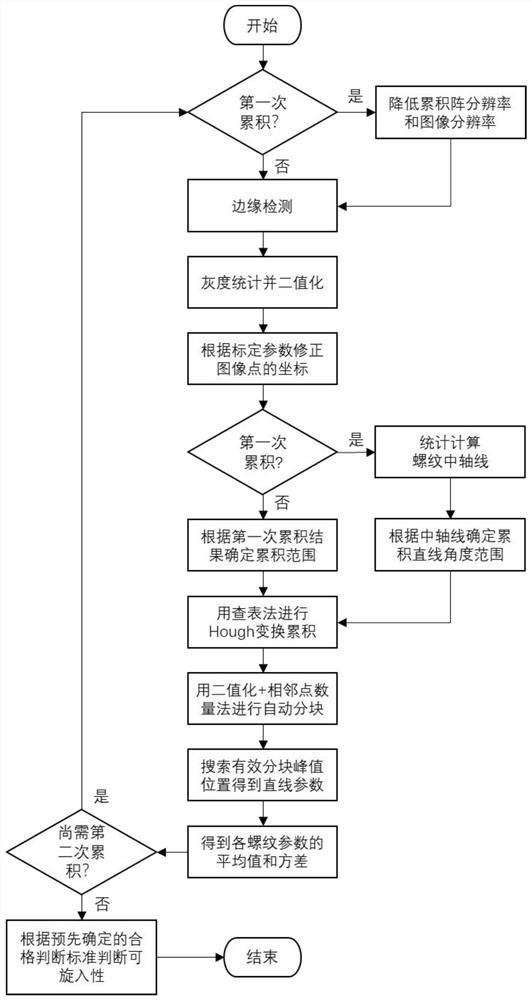

[0051] The present embodiment is a machine vision-based external thread detection method, wherein only one Hough transform accumulation is performed, and the main steps include:

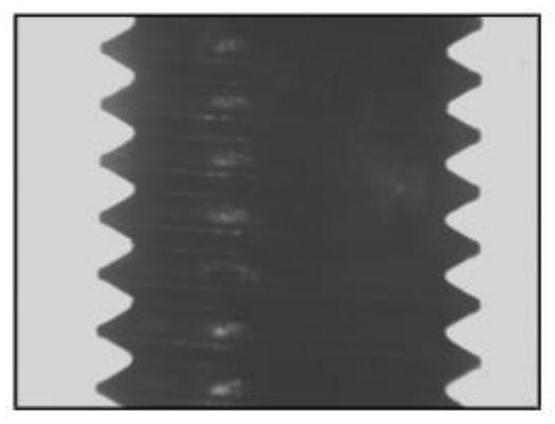

[0052] S1. Use parallel light pipe backlight and camera to obtain thread image, the thread axis is horizontal, but does not require a fixed direction, it can be realized by a simpler device, the camera is vertical, and the obtained image is partially as follows image 3 shown;

[0053] S1.1 Use the machine vision grid calibration plate to calibrate the image system: place the appropriate size grid plate in the corresponding horizontal position of the thread axis, and adjust the vertical and horizontal axes of the grid plate to coincide with the visual field axis;

[0054] S1.2 Obtain the image, and re-adjust the position of the grid plate if necessary; perform edge detection, statistical grayscale, and binarization; use high-resolution Hough transform to obtain straight line information, and calculat...

Embodiment 2

[0083] This embodiment is a case where two advanced Hough transform accumulations are performed. The main steps are similar to those of the first embodiment, and only the key steps of the advanced accumulation will be described below. More advanced accumulations can be made if necessary, but with diminishing marginal benefits.

[0084] The calculation is carried out according to the first embodiment, but the accumulation matrix with lower resolution is used to reduce the calculation amount. A lower resolution image can also be used at the same time to further reduce the amount of computation, but the effect is not as pronounced as reducing the resolution of the accumulation matrix. The resolution of the parameter ρ is taken as 1 pixel, the size of the θ accumulation matrix is 0.2 degrees (respectively reduced by 10 times and 4 times), and when the accumulation range of θ is relaxed to 16 degrees, the cumulative matrix size becomes 2472*80, compared to In case 1, the cumula...

Embodiment 3

[0088] Corresponding to the first embodiment, this embodiment is a real-time detection system for external threads based on machine vision, including an image preprocessing and calibration module, which calibrates image size and distortion; a system learning and screwability judgment standard generation module; real-time detection module, obtain external thread size information and judge its screwability; test report and process control chart generation module.

[0089] The specific functions of the modules in this embodiment correspond to the method steps in the first embodiment, and are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com