Keyway machining device for rudder hole of rudder

A technology for processing devices and rudder stock holes, applied to metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of large floor area, difficulty in switching sites, and huge keyway processing equipment, and achieve reasonable design and structure compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

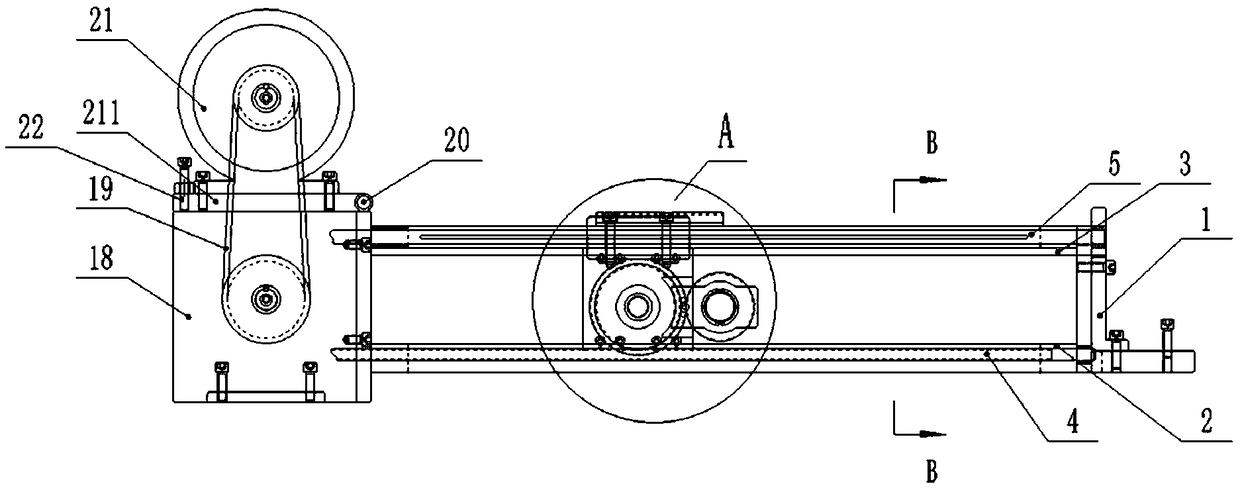

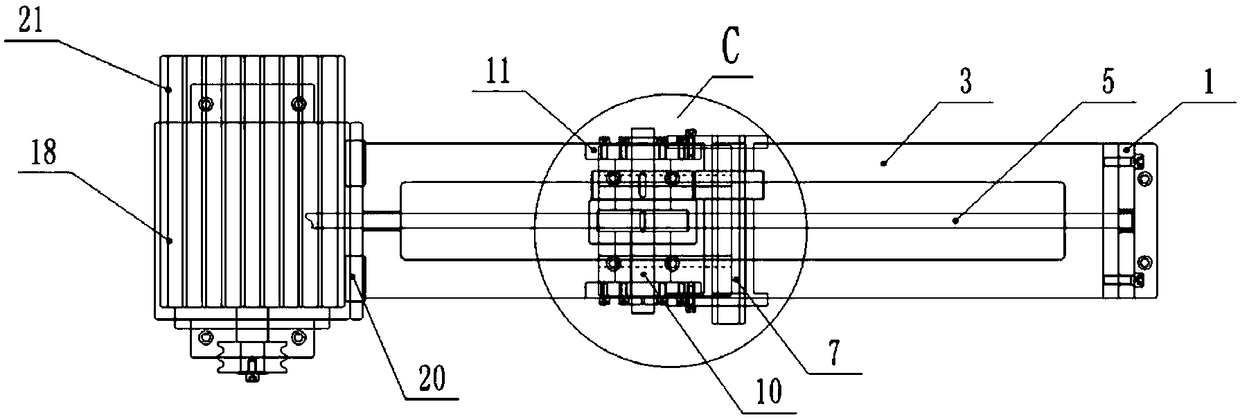

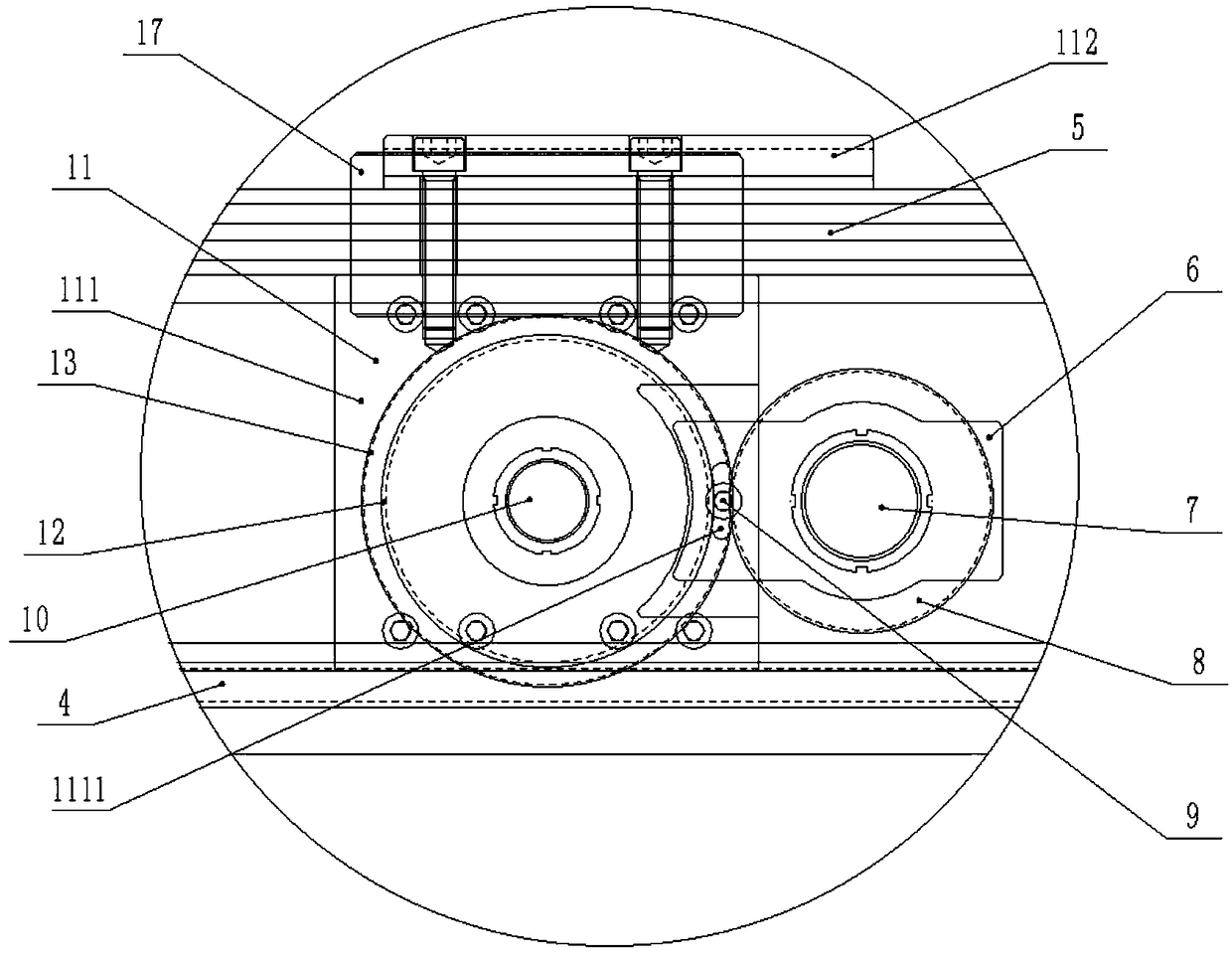

[0030] Such as figure 1 , figure 2 As shown, the keyway processing device for the rudder stock hole of a ship rudder according to the embodiment of the present invention includes a motor 21 and a reduction box 18 connected by transmission, the motor 21 is located above the reduction box 18, and the motor 21 and the reduction box 18 pass through the belt 19 transmission connection, the base 211 of the motor 21 is movably installed on the upper right corner of the reduction box 18 through the hinge 20, and the adjustment screw 22 is rotated on the left side of the base 211; The right end of the polished rod 5 and the screw rod 4 is fixed on the right side plate 1 and is equipped with a copper sleeve, the transition wheel 17 is sleeved on the polished rod 5, and the polished rod 5 is processed with a long groove 51 ( Figure 4 shown), the key is placed in the long groove 51, and the polished rod 5 drives the transition wheel 17 to rotate at the same speed through the key; Dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com