On-line fixed carbon system and on-line fixed carbon evaluation method for movable bed device catalyst, and movable bed device

A catalyst and moving bed technology, applied in chemical instruments and methods, measuring devices, chemical analysis by combustion, etc., can solve the problems of low automation and efficiency, inability to monitor performance in real time, asynchronous catalyst analysis and production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

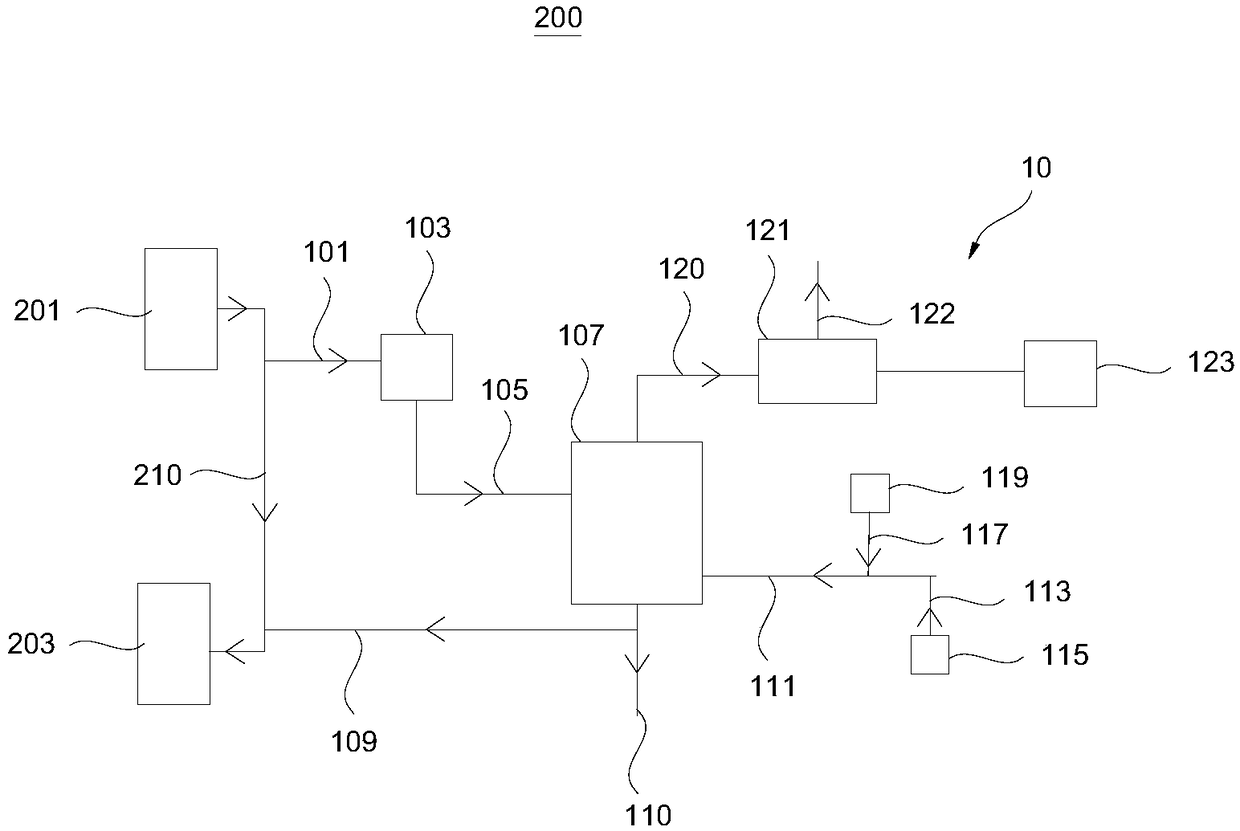

[0047] Please refer to attached figure 1 , the present embodiment provides an online carbon determination system 10 for the catalyst of the moving bed device 200, which includes:

[0048] The first catalyst delivery pipe 101, the catalyst quantitative device 103, the second catalyst delivery pipe 105, the coke measurement reactor 107, the coke flue gas delivery pipe 120, the flue gas analyzer 121, the catalyst discharge pipe 110, and the third catalyst delivery Pipe 109, gas delivery pipe 111, material level gauge and flue gas discharge pipe 122. The online carbon determination system 10 can detect the amount of carbon deposition of the catalyst in the moving bed device 200 online and in real time, so as to determine the activity state of the catalyst in the moving bed device 200 .

[0049] Further, the discharge end of the first catalyst delivery pipe 101 is connected with the catalyst quantitative device 103, and the feed end of the first catalyst delivery pipe 101 is used ...

no. 2 example

[0067] This embodiment provides a moving bed device 200, which includes the online carbon determination system 10 provided in the first embodiment, please refer to the attached figure 1 , figure 1 The arrows in are the flow direction of the catalyst or the flow direction of the flue gas.

[0068] Specifically, the mobile device includes a reactor 201 and a regenerator 203 , and in this embodiment, a catalyst external circulation pipe 210 is provided between the reactor 201 and the regenerator 203 . The feed end of the catalyst external circulation pipe 210 is connected to the reactor 201 , and the discharge end of the catalyst external circulation pipe 210 is connected to the regenerator 203 . A small amount of catalyst is taken out from the reactor 201, and is continuously and stably transported to the regenerator 203 through the catalyst external circulation pipe 210 when not analyzing and sampling. The catalyst external circulation pipe 210 establishes a small circulation ...

no. 3 example

[0073] This embodiment provides a method for using the moving bed device 200 provided in the second embodiment to perform online carbon determination evaluation, and the specific steps are as follows:

[0074] System preparation:

[0075] Open the data processing terminal 123, preheat the flue gas analyzer 121 so that the flue gas analyzer 121 enters and maintains the ready state; open the nitrogen gas flow meter on the nitrogen gas delivery pipe 113 in the gas delivery pipe 111, and purge the reaction test system;

[0076] Catalyst collection and filling:

[0077] The catalyst is delivered intermittently or regularly from the catalyst external circulation pipe 210 of the moving bed device 200 through the first catalyst delivery pipe 101 to the catalyst quantitative device 103 for quantification. The last 3kg of catalyst enters into the coke measurement reactor 107 through the second catalyst delivery pipe 105, and carries out coke regeneration;

[0078] Scorch measurement r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com