Grabbing mechanism used for sectional material traction and grabbing method thereof

A profile and grasping technology, applied in the directions of manipulators, chucks, manufacturing tools, etc., can solve the problems of reducing the versatility and practicability of traction equipment, increasing the production and processing costs of enterprises, and achieving strong practicability, improving balance stability, Universal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

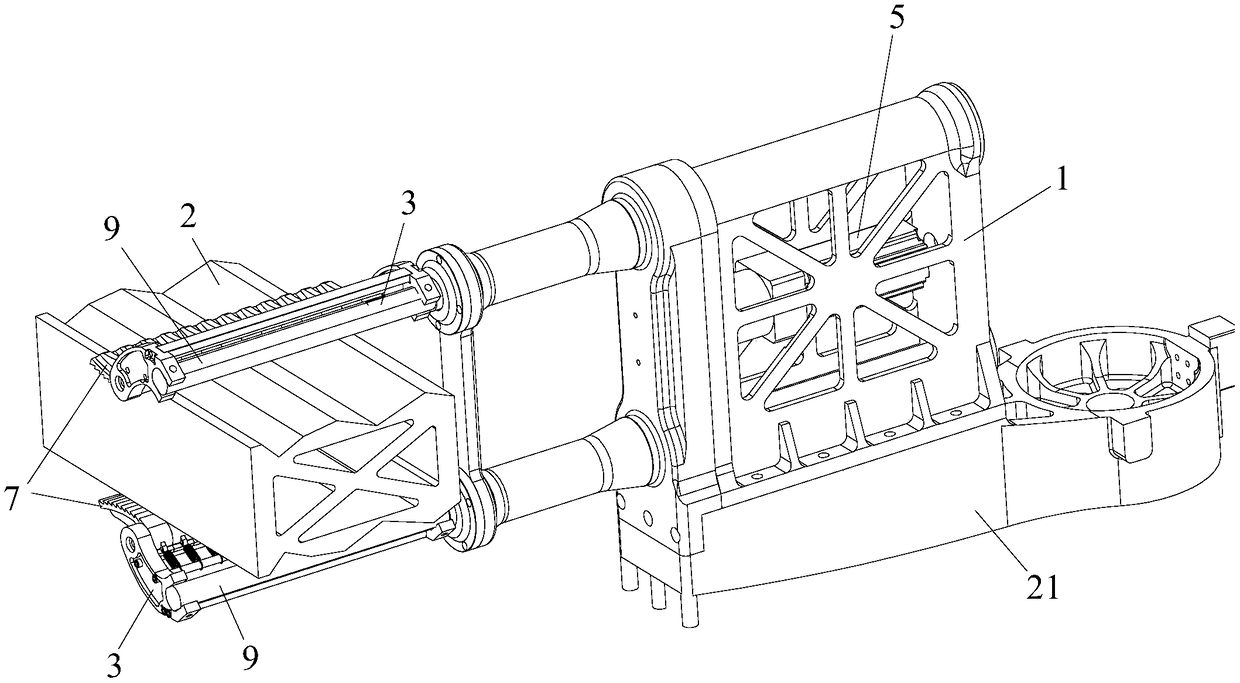

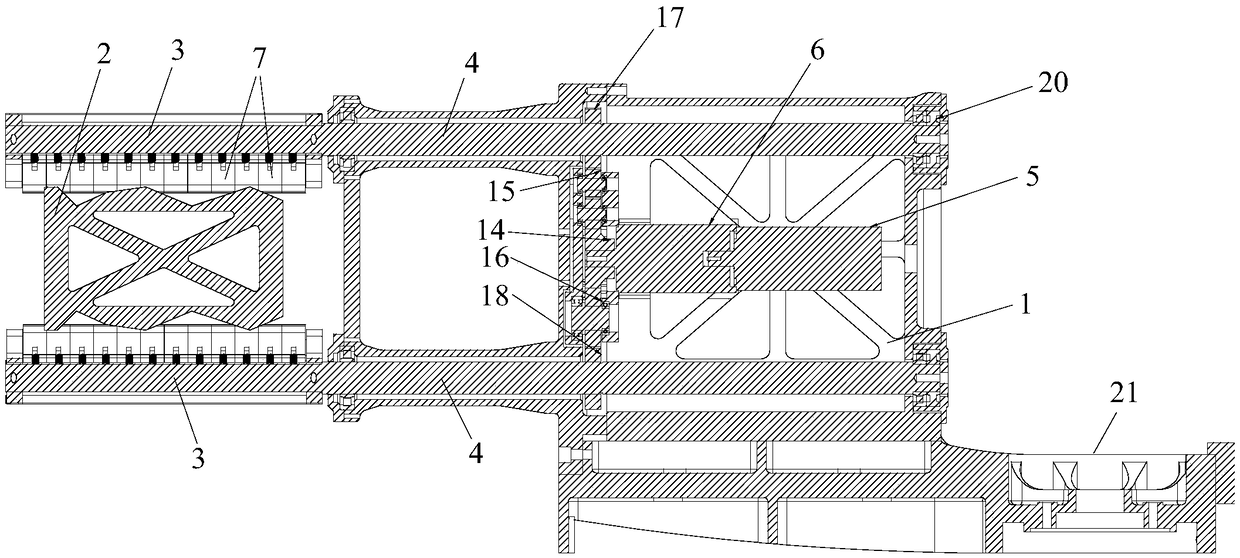

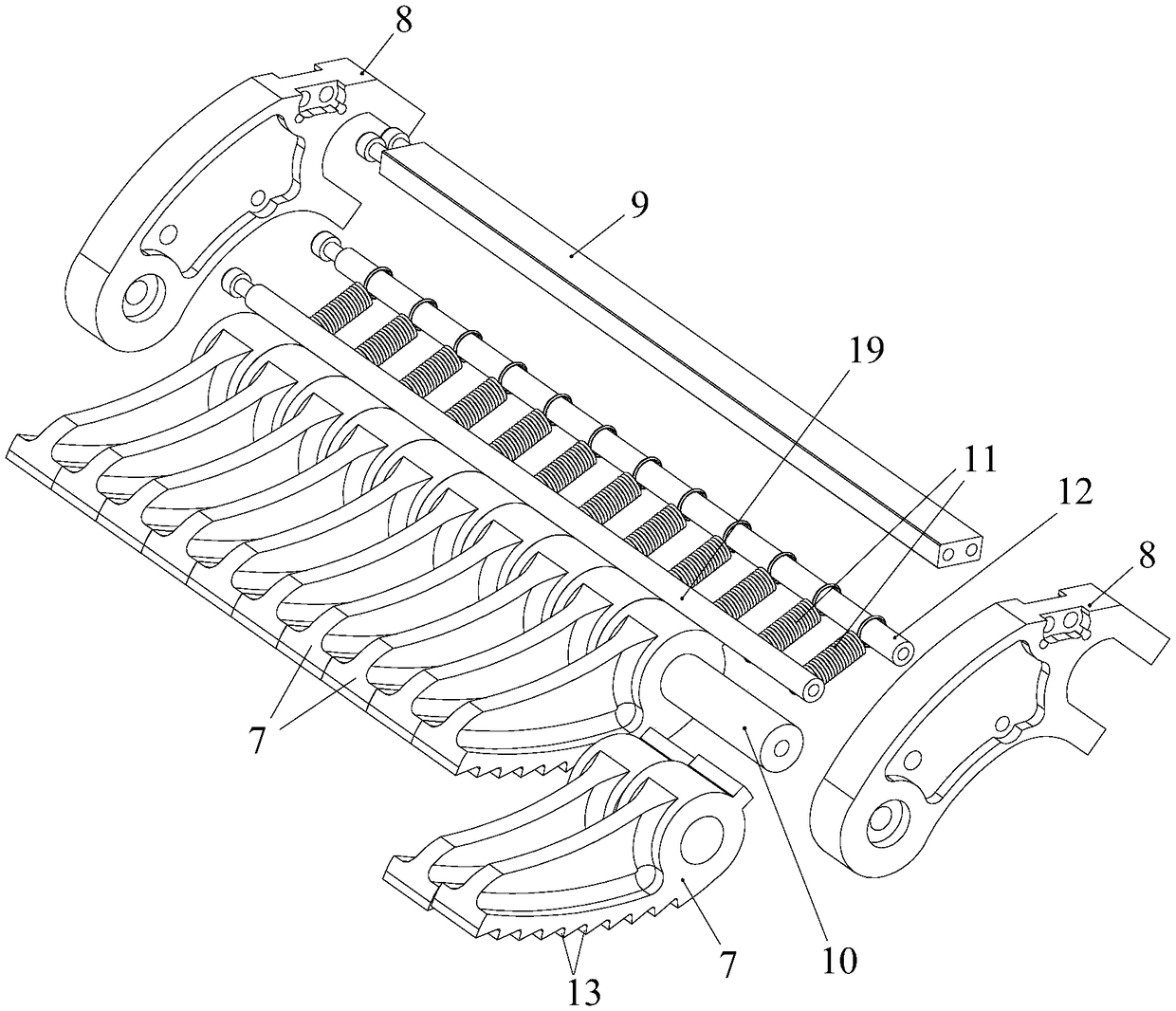

[0029] like Figure 1 to Figure 4 As shown, a gripping mechanism for profile traction of the present invention includes an arm 21, a power box 1 connected to the arm 21, a drive component and a transmission module arranged in the power box 1, and the profile 2 is grasped respectively. Two gripper modules 3 and two rotating shafts 4 pierced in the power box 1, wherein the driving part is connected by a torque motor 5 and a reducer 6; the transmission module is connected to the The two gripper modules 3 are connected, and the two gripper modules 3 are set up and down oppositely in a mirror-symmetrical manner. The driving part is connected with the transmission module. When working, the driving part drives the two rotating shafts 4 to rotate in reverse through the transmission module to drive the two mirror-symmetric gripper modules 3 to rotate outwards in reverse to realize the unloading of the profile 2, or The grasping of the profile 2 is achieved by driving the two mirror-sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com