Steel strip punching-off device

A steel belt and punch technology, applied in the field of machining automation, can solve the problems of easy sliding and displacement of the steel belt, unguaranteed accuracy, low efficiency of manual punching, etc., saving manpower, high work efficiency, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

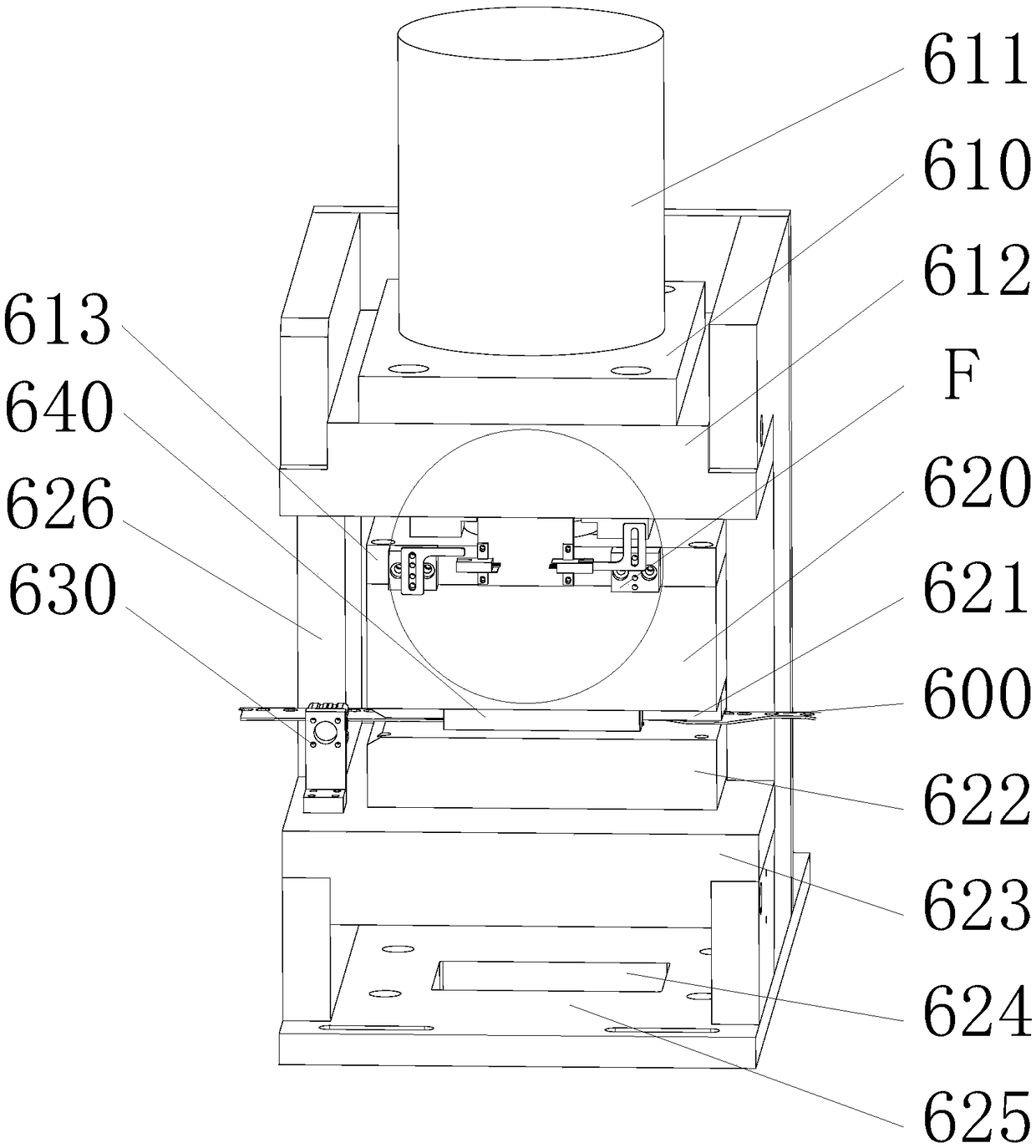

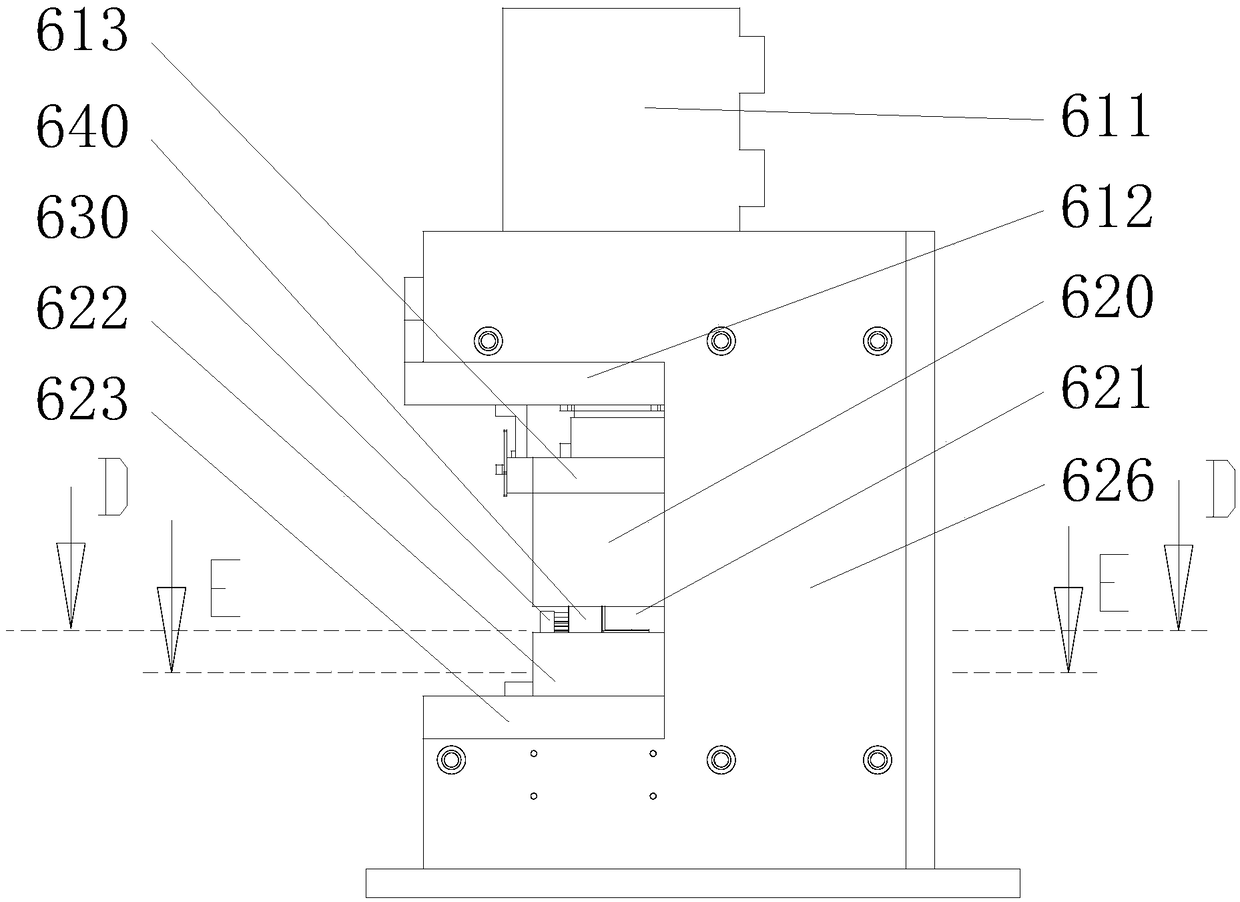

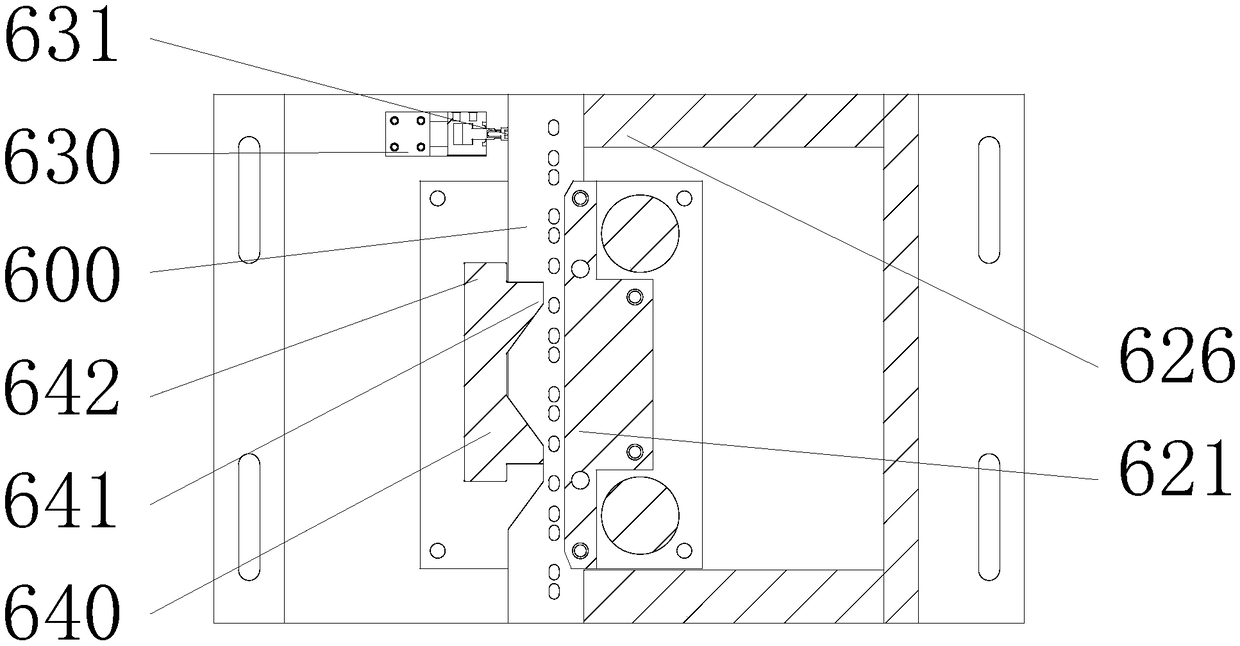

[0029] refer to Figure 1 ~ Figure 4 As shown, it is a steel strip punching unit, including punching unit upper fixing parts 621 and punching unit lower fixing parts 622 respectively arranged on the upper and lower sides of the steel strip, and the punching unit upper fixing parts 621 press the steel strip. On one side, the other side of the steel strip is provided with a stamping unit upper die set 640, and the punching unit upper die set 640 moves up and down under the action of the punching unit drive source 611 to stamp the steel strip. The unit upper die group 640 includes punching into a unit rectangle upper die 642, the downward projection surface of the punching into a unit rectangle upper die 642 is not on the steel strip, and two punched into unit rectangle upper dies 642 are distributed on one side. Unit trapezoidal upper die 641, the downward projection surface of the punching unit trapezoidal upper die 641 is on the steel belt, and the lower fixing part 622 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com