Automatic IC burning machine

A technology of machinery and programming seat, which is applied in the field of automatic IC programming machinery, which can solve the problems of many operations, mixing of unprogrammed ICs, and being easily affected by human static electricity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following are only preferred embodiments of the present invention, and are not intended to limit the protection scope of the present invention.

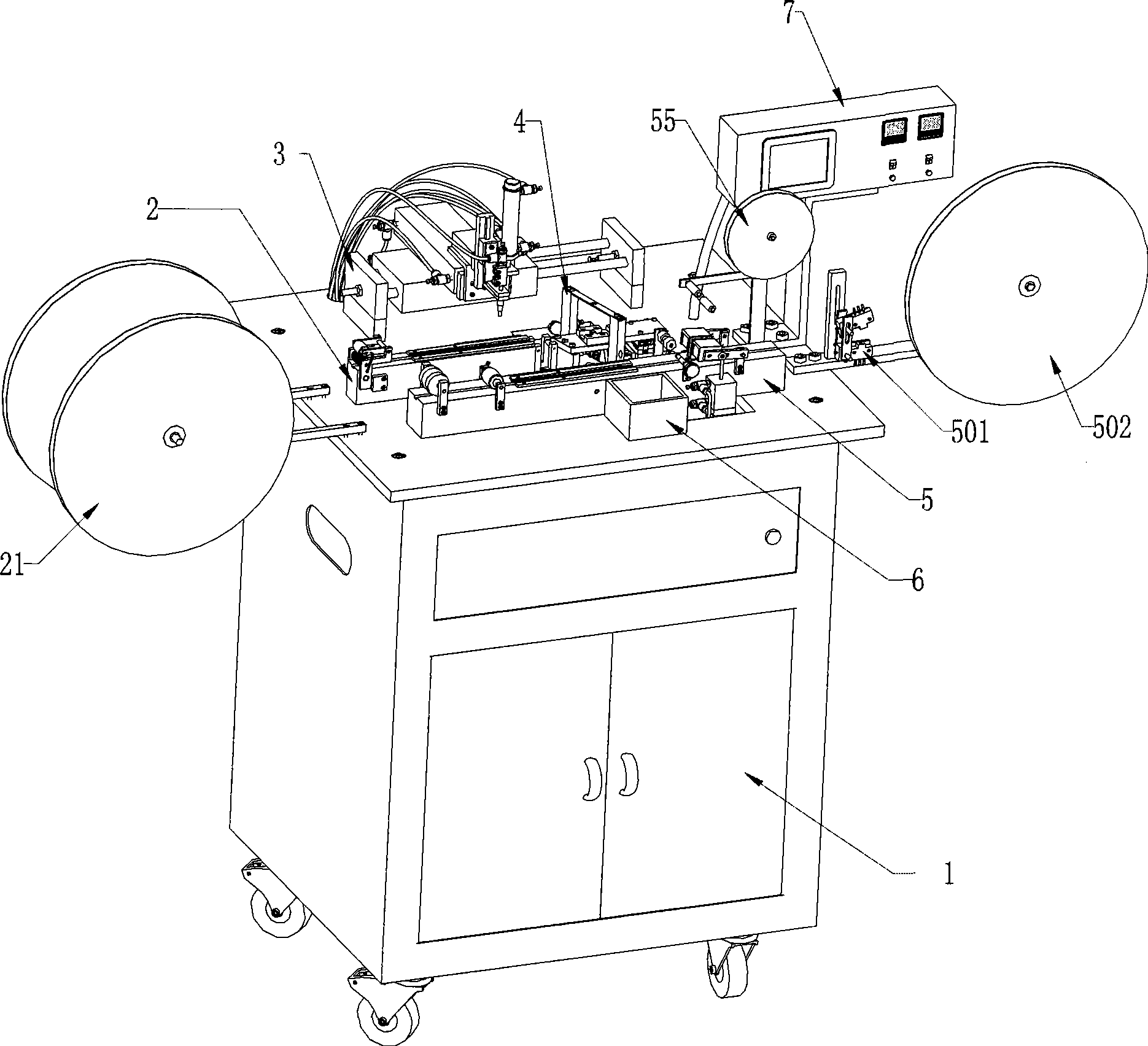

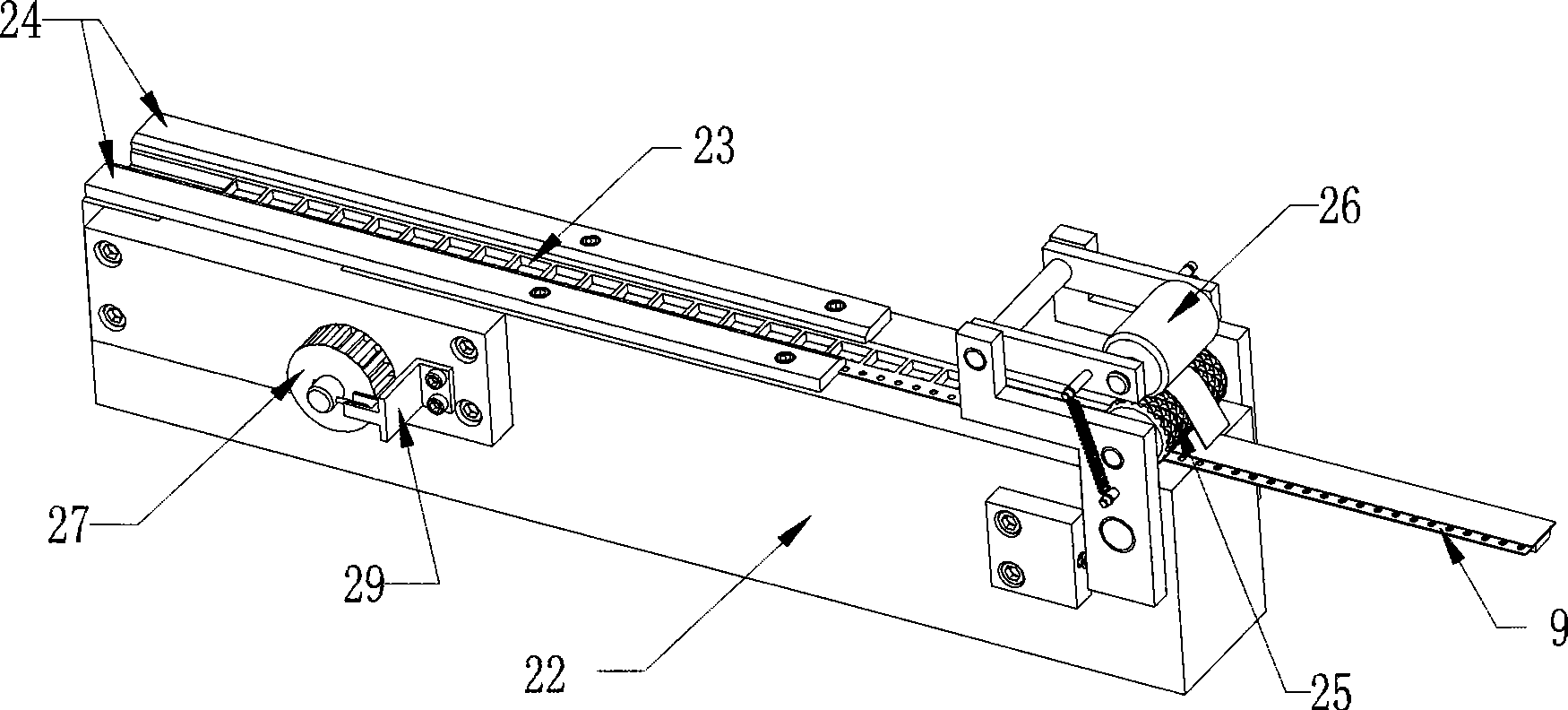

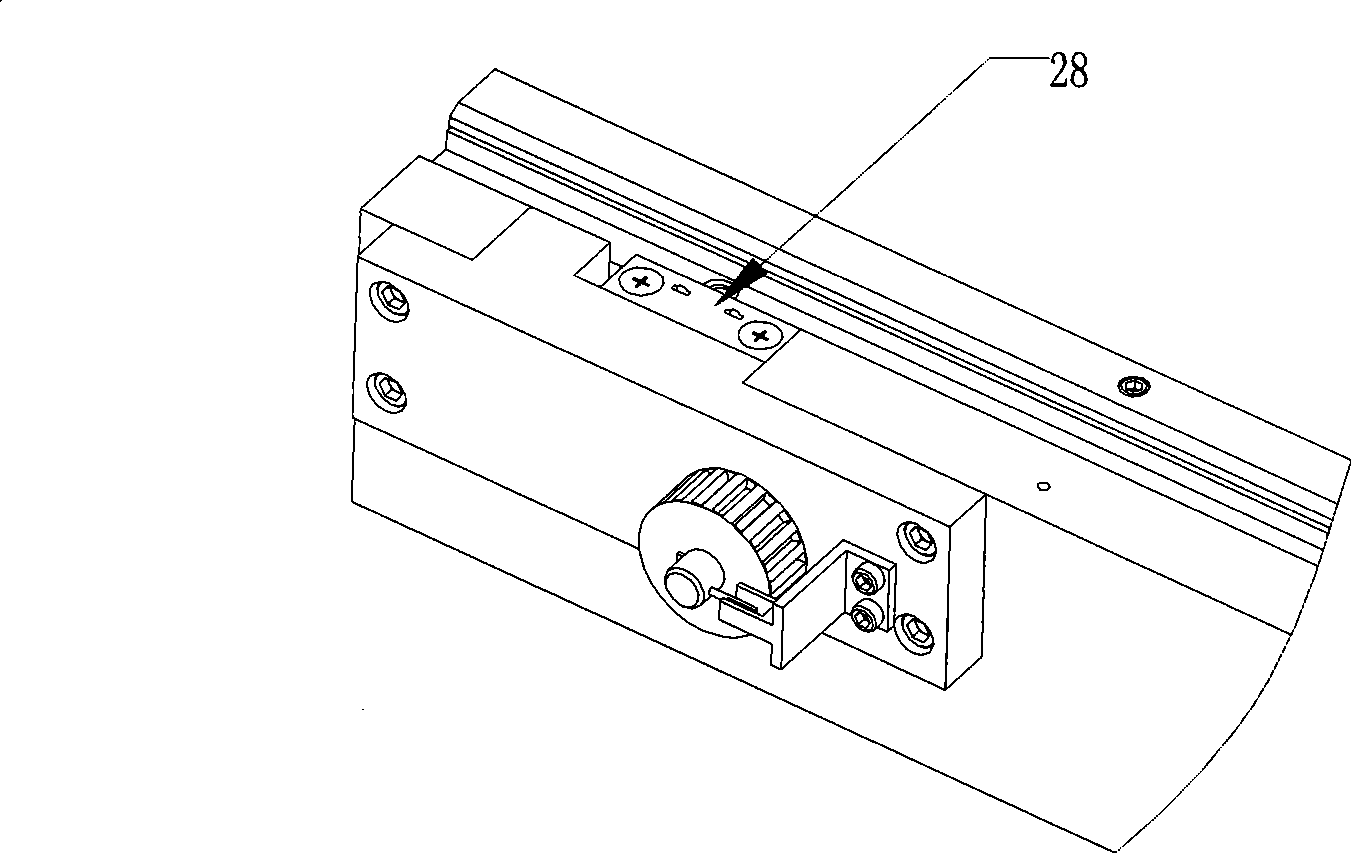

[0023] See Figure 1-7 As shown, a kind of automation IC burner machine that the present invention provides, it comprises: Stripping feeding mechanism 2, conveying suction mechanism 3, burning device 4, packaging device 5 and electric control cabinet 1, described stripping feeding mechanism 2. The conveying and absorbing mechanism 3, the programming device 4 and the packaging device 5 are installed on the platform on the upper surface of the electric control cabinet 1, and the stripping and feeding mechanism 2, the conveying and absorbing mechanism 3, the programming device 4 and the packaging device 5 are arranged on the electric control cabinet 1. The control pneumatic device of the PLC control panel in the control cabinet 1 is realized. The stripping and feeding mechanism 2 transfers the packaged IC material roll 21 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com