Adjustable valve plate stamping die

A stamping die, adjustable technology, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of rising production costs, waste of time, inconvenient maintenance, etc., to achieve the effect of wasting manpower and material resources and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

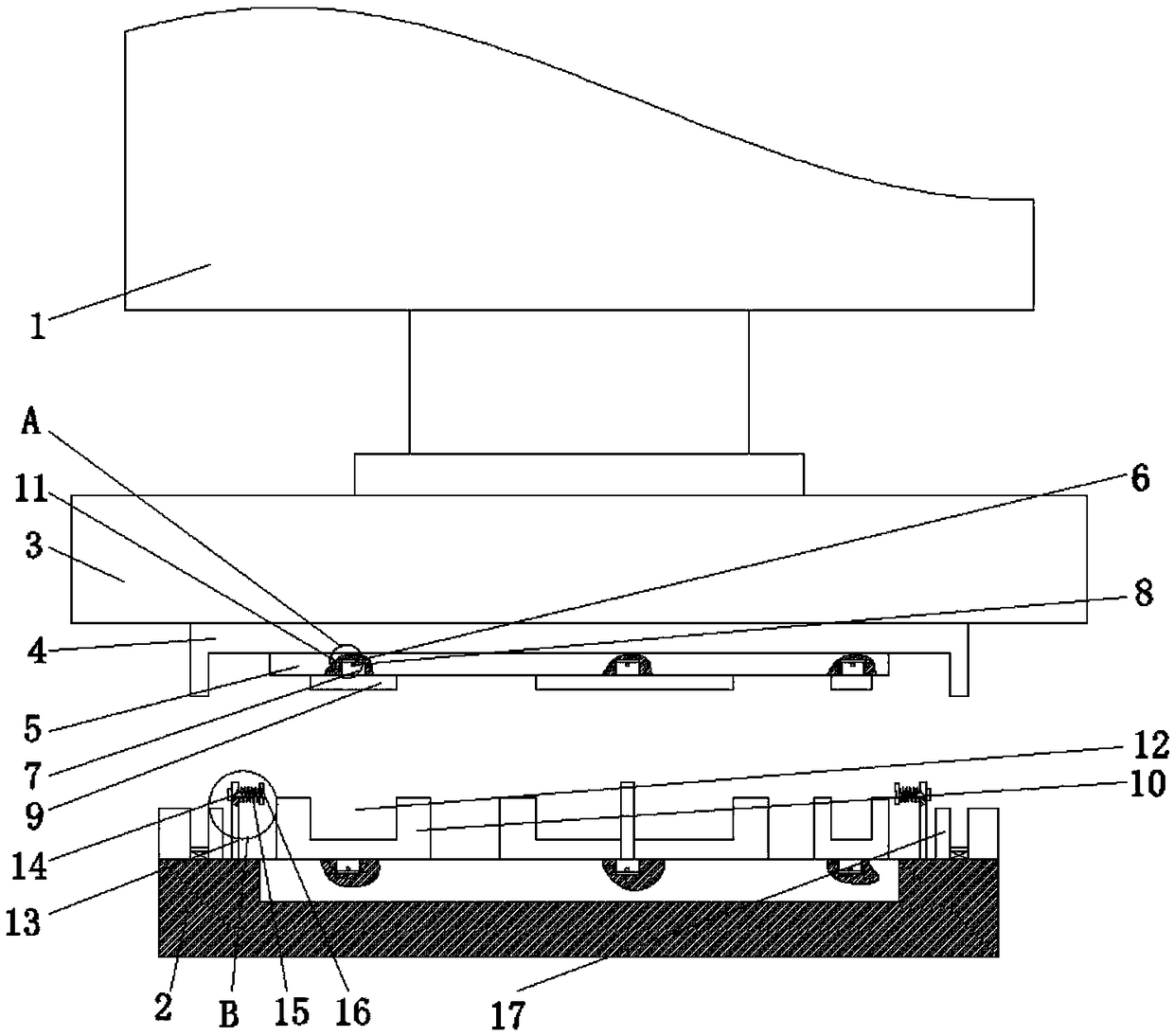

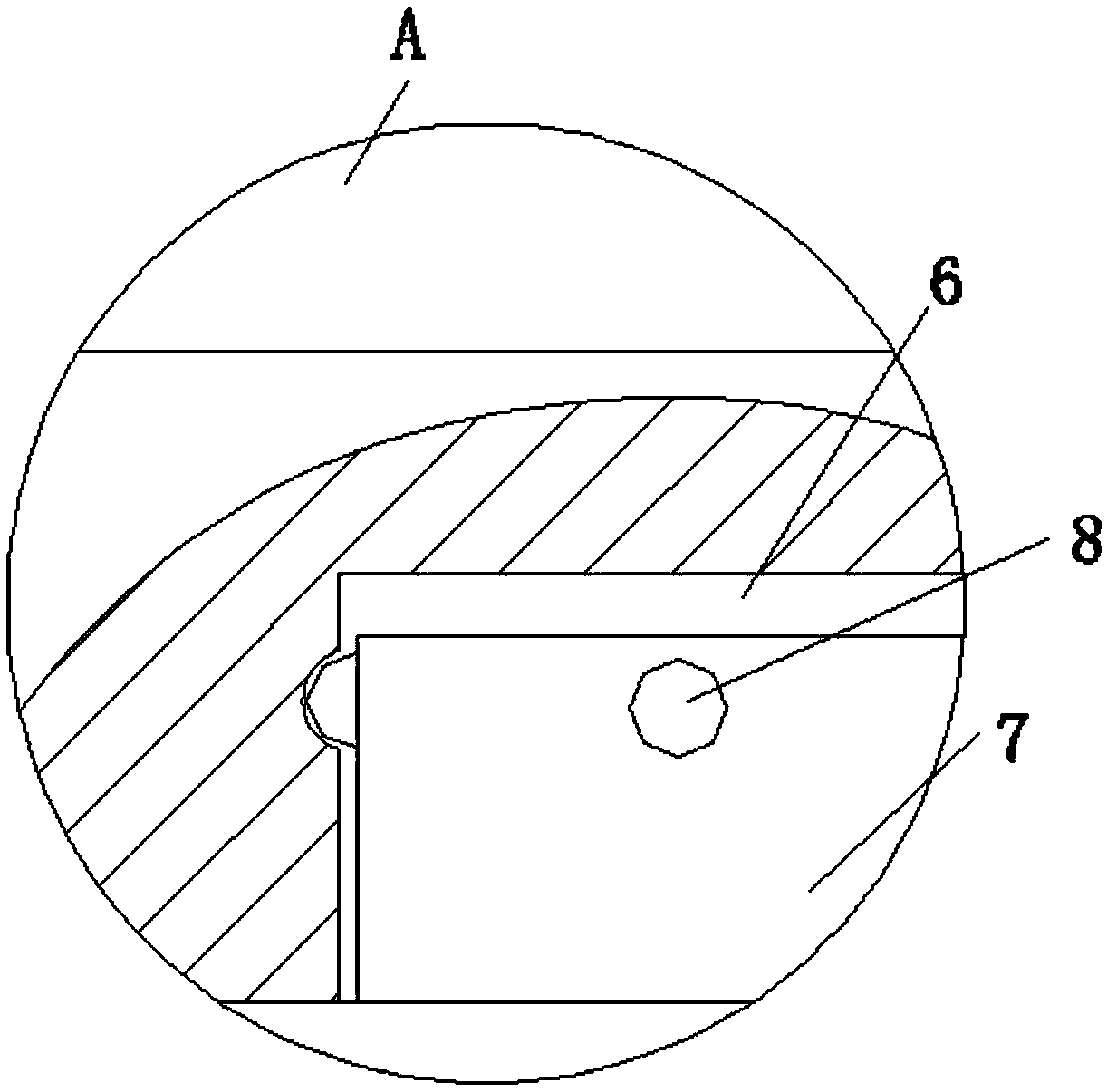

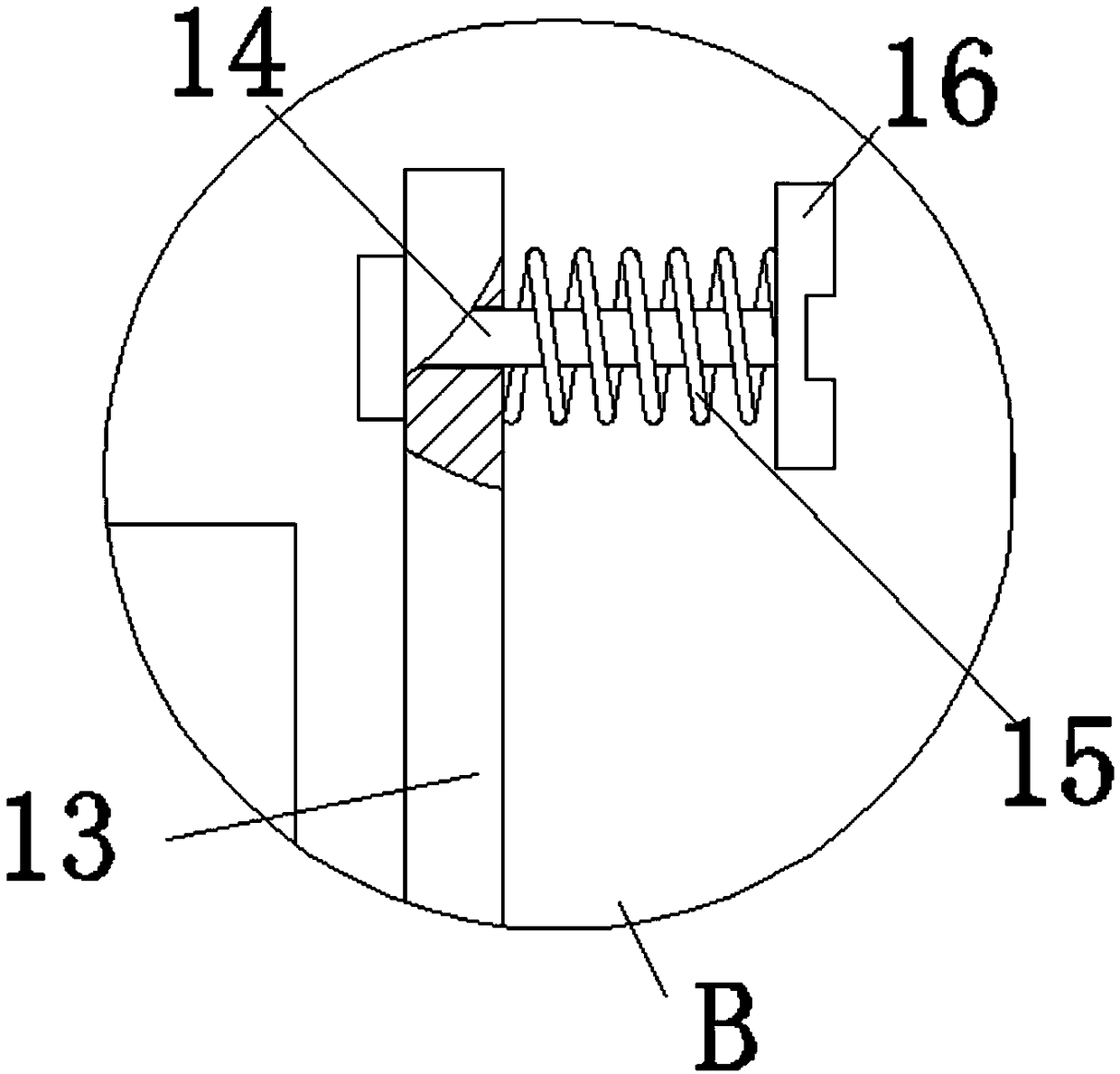

[0018] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below in conjunction with specific embodiments.

[0019] Such as Figure 1-4 As shown, an adjustable valve sheet stamping die, the adjustable valve sheet stamping die, includes a punching power seat 1, a base 2. The punching power seat 1 is provided with a hydraulic power body 3 in the middle of one side close to the base 2, and The side of the power body 3 close to the base 2 is provided with a limited mold base 4, and the inner surface of the limited mold base 4 close to the base 2 and the top inner surface of the base 2 are movably connected with a detachable mold base 5 at a mutually symmetrical position.

[0020] The present invention relates to an adjustable valve sheet stamping die. The bayonet bead and the embedding groove are movably connected through the bayonet bead provided on the shaft. The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com