Coated sand mold loading and positioning installation template

A technology for positioning, installing and installing templates, which is applied in the directions of manufacturing tools, casting and molding equipment, and parts of molding machines. The effect of manpower and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

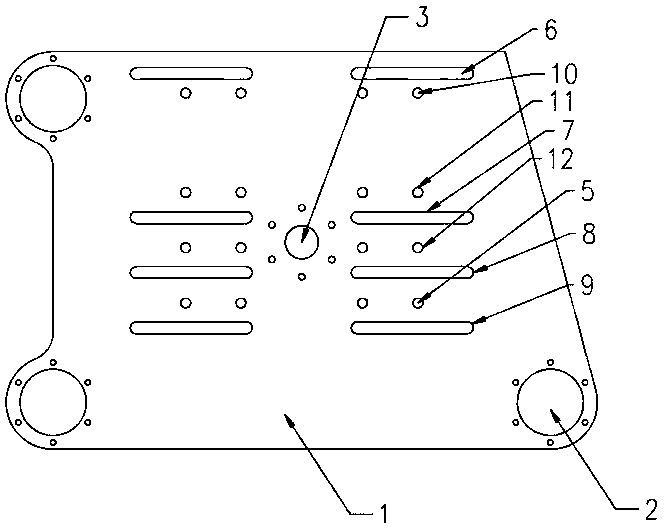

[0022] Embodiment 1: as figure 1 and 2 The shown coated sand mold clamping and positioning installation template includes a body 1 of the installation template, guide holes 2 are provided around the body 1, a fixing hole 3 is provided in the middle of the body 1, and the body 1 on both sides of the fixing hole 3 There are strip-shaped channel groups and circular channel groups arranged symmetrically on the upper part. The strip-shaped tunnel group includes a first strip-shaped tunnel 6, a second strip-shaped tunnel 7, a third strip-shaped tunnel 8, and a fourth strip-shaped tunnel 9 arranged sequentially from top to bottom on the body 1; the circular tunnel The group includes two first circular tunnels 10 arranged side by side below the first strip-shaped tunnel 6, two second circular tunnels 11 arranged side by side above the second strip-shaped tunnel 7, and arranged side by side at the third strip-shaped tunnel 8 The two upper third circular holes 12 and the two fourth ci...

Embodiment 2

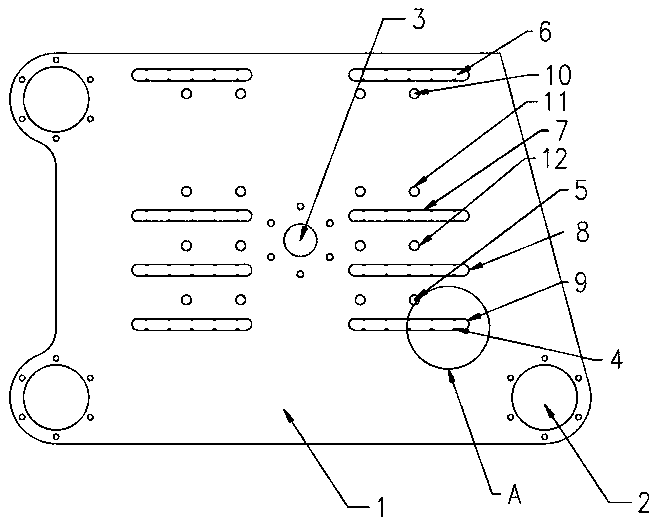

[0025] Embodiment 2: be optimal embodiment of the present invention, as figure 2 , 3 4. The coated sand mold clamping and positioning installation template shown in 4 includes a body 1 of the installation template. Guide holes 2 are arranged around the body 1, and a fixing hole 3 is arranged in the middle of the body 1. The fixing holes 3 on both sides of the fixing hole 3 The main body 1 is symmetrically provided with a strip-shaped channel group and a circular channel group. The strip-shaped tunnel group includes a first strip-shaped tunnel 6, a second strip-shaped tunnel 7, a third strip-shaped tunnel 8, and a fourth strip-shaped tunnel 9 arranged sequentially from top to bottom on the body 1; the circular tunnel The group includes two first circular tunnels 10 arranged side by side below the first strip-shaped tunnel 6, two second circular tunnels 11 arranged side by side above the second strip-shaped tunnel 7, and arranged side by side at the third strip-shaped tunnel 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com