External combustion engine and method of operation thereof

An engine and external combustion technology, applied to combustion engines, engine components, machines/engines, etc., can solve problems such as high fuel quality requirements, insufficient fuel combustion, high material requirements, etc., to reduce engine structure, improve efficiency, The effect of high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Now in conjunction with the accompanying drawings, the present invention will be further described by taking specific implementation as an example.

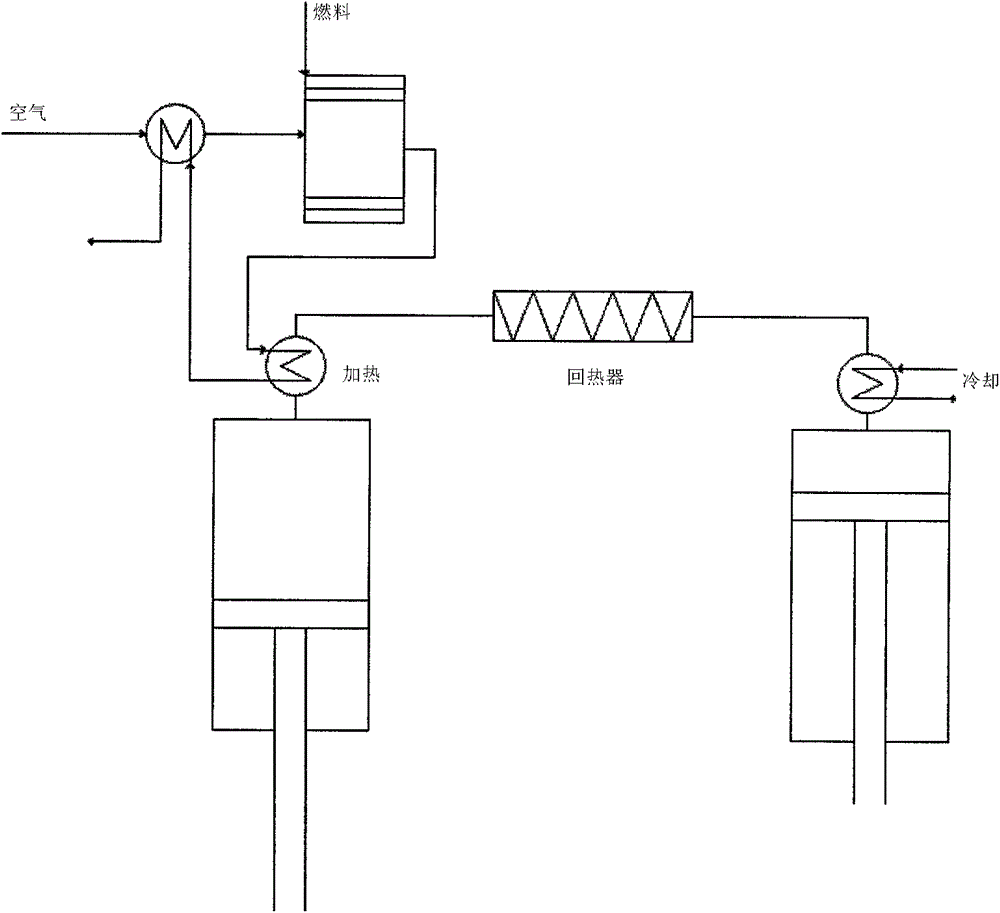

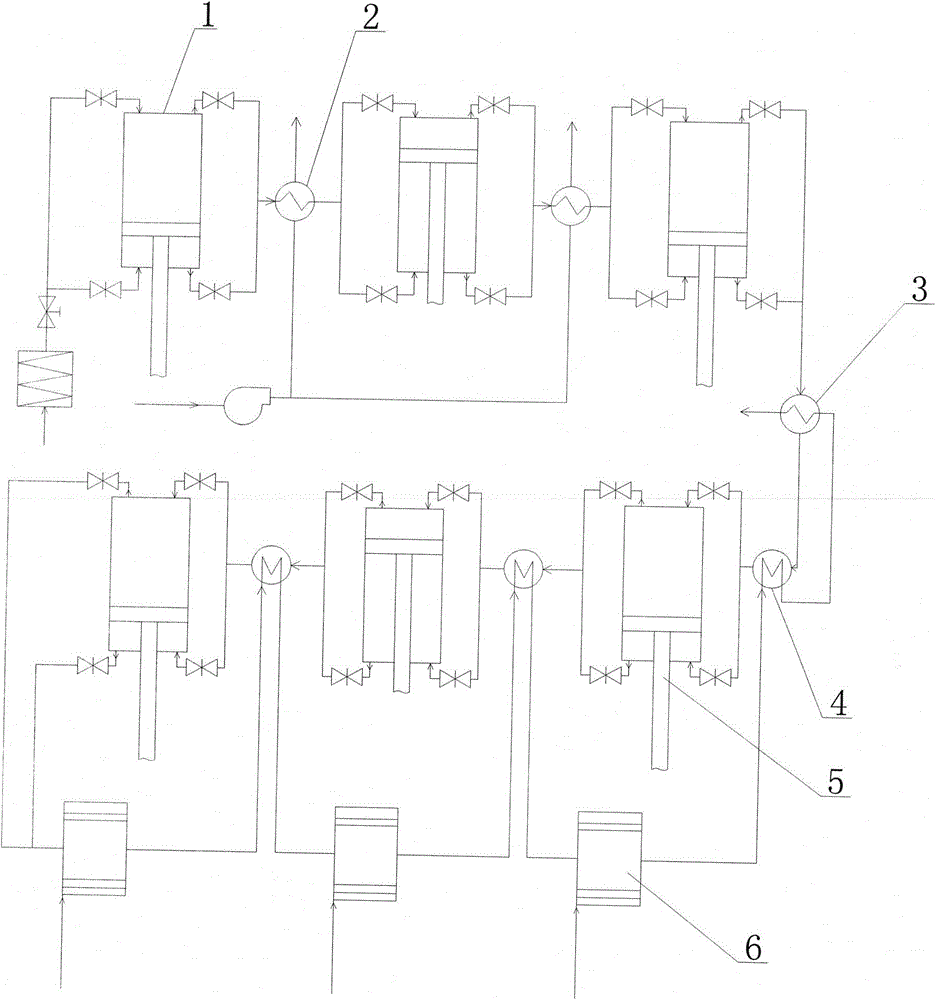

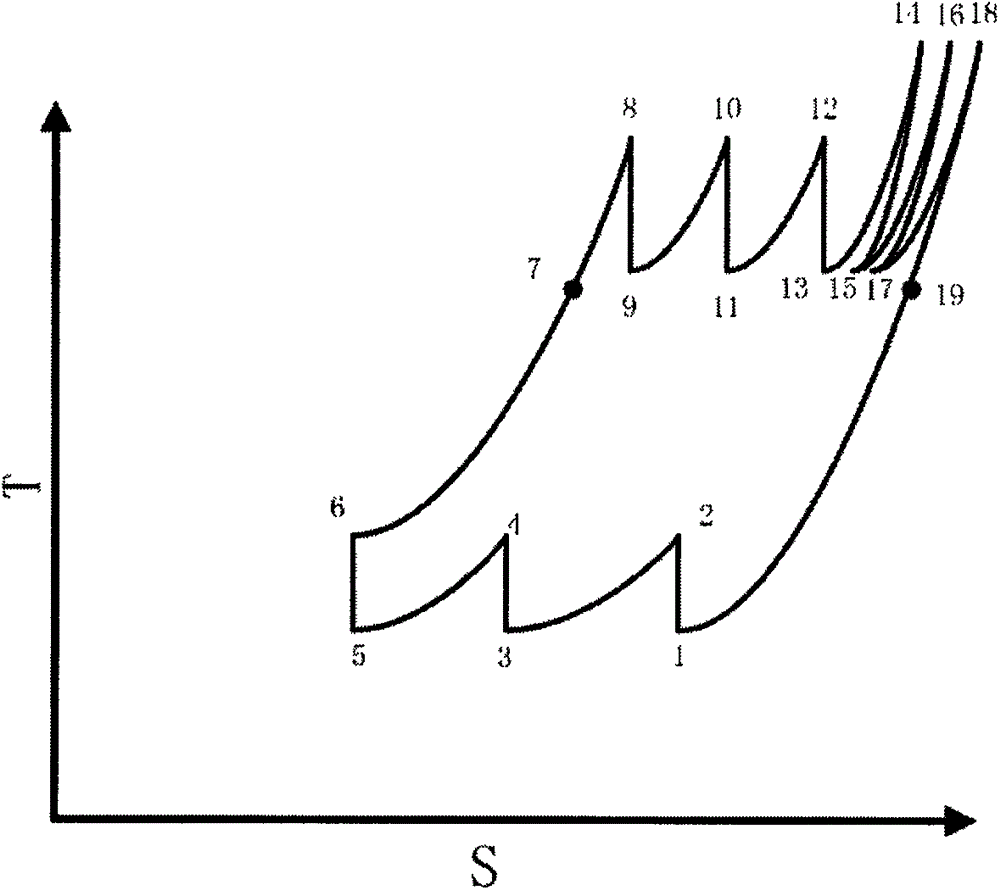

[0032] Such as figure 1 As shown, the external combustion engine mainly includes three double-acting compressors, two coolers, one recuperator, three double-acting expanders, three heaters, three combustion chambers, air valves and air filters , the specific structural connection is: three double-acting compressors are connected in series, and a cooler is installed between two adjacent double-acting compressors, and two pipes come out from the exhaust ports at both ends of the cylinder of the first-stage double-acting compressor. The pipelines are merged and connected to the inlet of the cold fluid side of the primary cooler, and the pipeline at the outlet of the cold fluid side of the cooler is divided into two circuits again to connect to the two air inlets at both ends of the cylinder of the secondary double-acting com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com