Machining clamp of automobile interior trim part

A technology of automotive interior parts and fixtures, which is applied in the direction of manufacturing tools and workpiece clamping devices, can solve the problems of inconvenient processing, low work efficiency, and low precision, and achieve reduced design and production costs, safe and stable clamping, and Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

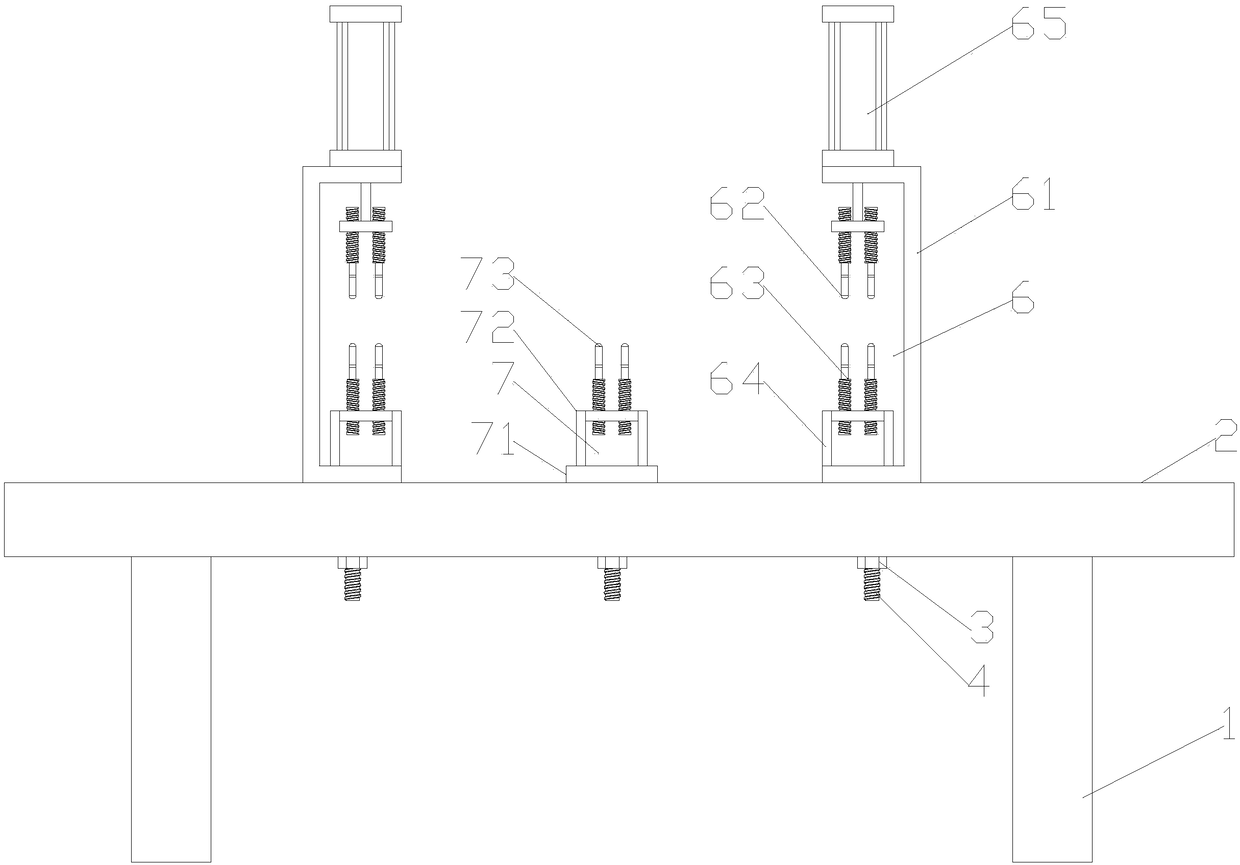

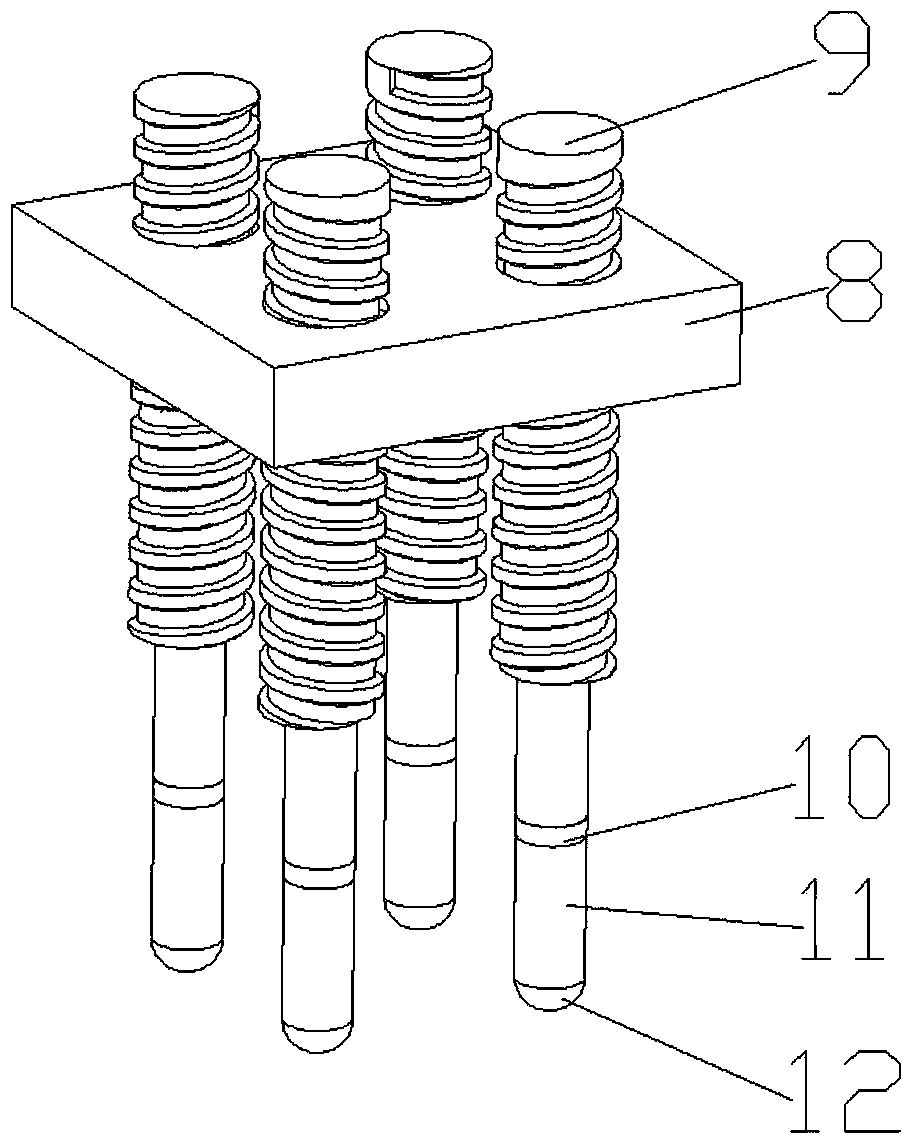

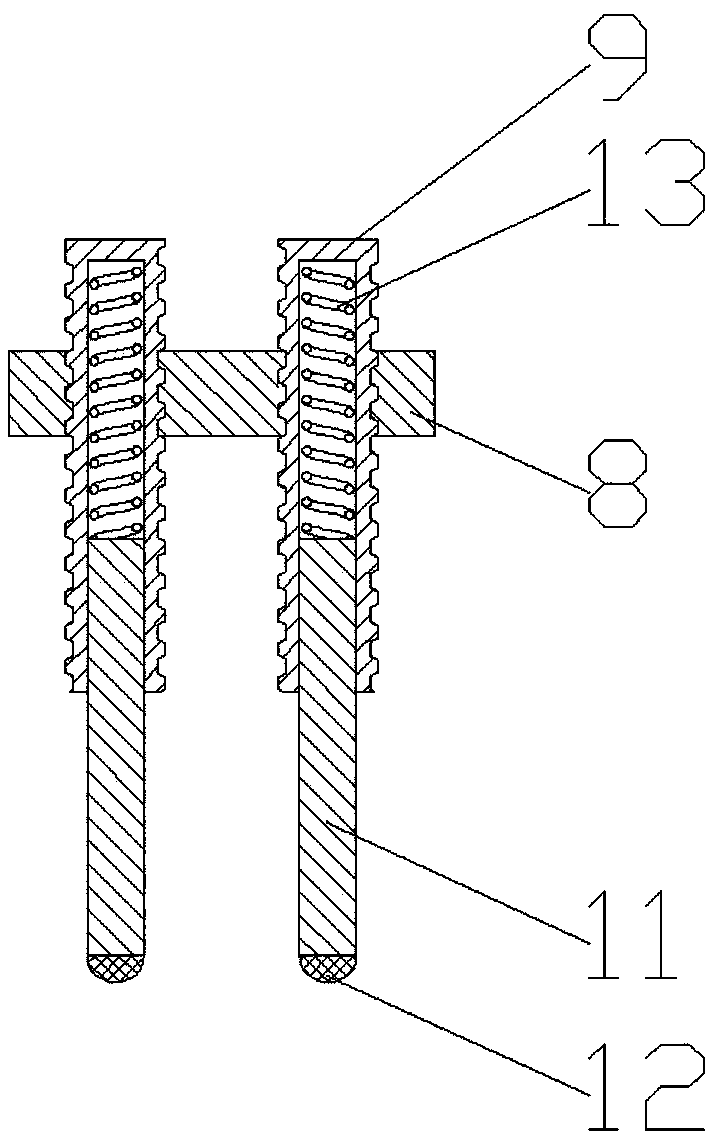

[0027] Select a certain number of clamping units 6 according to the outer contour of the interior trim, so that they are distributed along the outer contour, insert the fixing screw 4 of the clamping unit 6 into the fixing hole 5, and tighten and fix the bottom with the locking bolt 3, for For interior parts with a large area, select a certain number of support units 7 at the lower end of the middle part of the interior part, insert the fixing screw 4 of the support unit 7 into the fixing hole 5, and tighten the bottom with the locking bolt 3 to fix the interior part. Place it on the upper end of the support device 1 63, turn the hollow screw 9 of the clamping device 62 to make it rotate upwards, move the hollow screw 9 to the upper position first, and start the cylinder 65 to extend the clamping device 62 downward until the piston When the rod reaches the longest position, turn the four hollow screw rods 9 on the clamping device 62, so that the hollow screw rods 9 on the clamp...

Embodiment 2

[0029] Such as Figure 4 As shown, there are four clamping units 6 and two supporting units 7. This combination method is used when processing rectangular interior parts. For example, when drilling the inner roof of a car, the four sides of the inner roof of the car have a certain inclination angle. , the four vertices of the inner roof of the car are respectively placed between the support device one 63 and the clamping device 62, and the middle part of the inner roof of the car is supported by the support unit 7, so that the inner roof of the car will not sag like the bottom when the punching operation is carried out.

Embodiment 3

[0031] Such as Figure 5 As shown, there are three clamping units 6 and one supporting unit 7. This combination method is used when processing the interior trim of the triangle shape. For example, when processing the interior trim panel of the left front door of the car, the three Two corners are respectively put into the supporting device one 63, and the control cylinder 65 clamps the left front door trim panel with the clamping device 62, and the center of the left front door trim panel is supported by the support unit 7, so that the middle part will not be affected by the process when it is processed. The force bends the deformation downward.

[0032]Based on the above, the clamping unit 6 and the supporting unit 7 of the present invention can be used in any number of combinations, suitable for interior components of different sizes and shapes, and the scope of application is wider than that of special clamps. Reduce the design and production cost of special fixtures, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com