Dumper lifting hydraulic cylinder simulation working condition test device

A test device and technology of hydraulic cylinders, applied in the field of hydraulic cylinders, can solve the problems of disassembly, return to the factory, high repair costs, car crashes, failure to verify the performance of hydraulic cylinders, etc., and achieve low design and production costs, simple principles and structures. , the effect of avoiding collision damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following is a specific embodiment of the present invention, and the present invention will be further described in conjunction with the accompanying drawings.

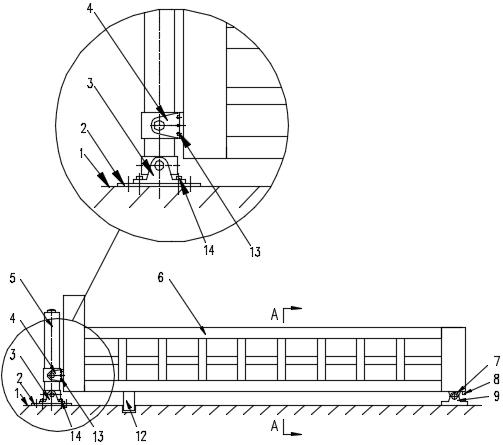

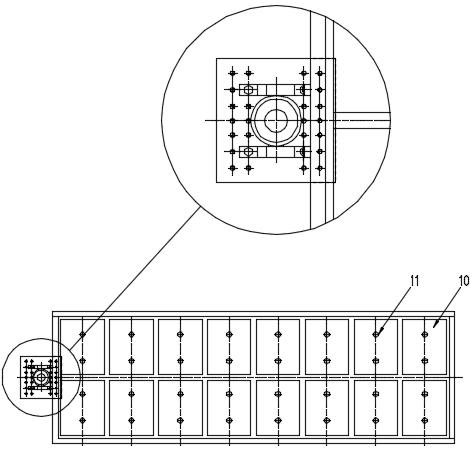

[0023] combine Figure 1 to Figure 4 As shown, a dump truck lifting hydraulic cylinder simulated working condition test device, including the tested hydraulic cylinder 5, a simulated installation stand and a loading device.

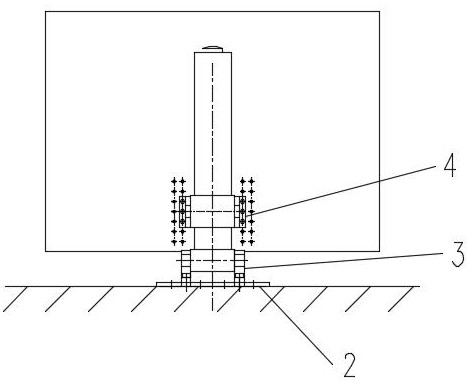

[0024] The simulated installation stand includes a foundation 1 and a loading compartment 6 . The fixed base plate 2 is fixed on the foundation 1 by anchor bolts, and a plurality of rectangularly distributed threaded holes are opened on the fixed base plate 2, and the threaded holes of the fixed base plate 2 are connected with a support I3. Support I3 is hinged with the pin shaft of cylinder 5 of the tested hydraulic cylinder. The front end of the loading compartment 6 is provided with a plurality of threaded holes distributed in a rectangular shape, and the threaded holes at the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com