Spliced type door-window system

A splicing type, door and window technology, applied in the installation of window glass, sealing devices, etc., can solve the problems of inconvenient installation, high design and production costs, and many types of material preparation, so as to achieve less material preparation, save design and production costs, and improve airtightness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

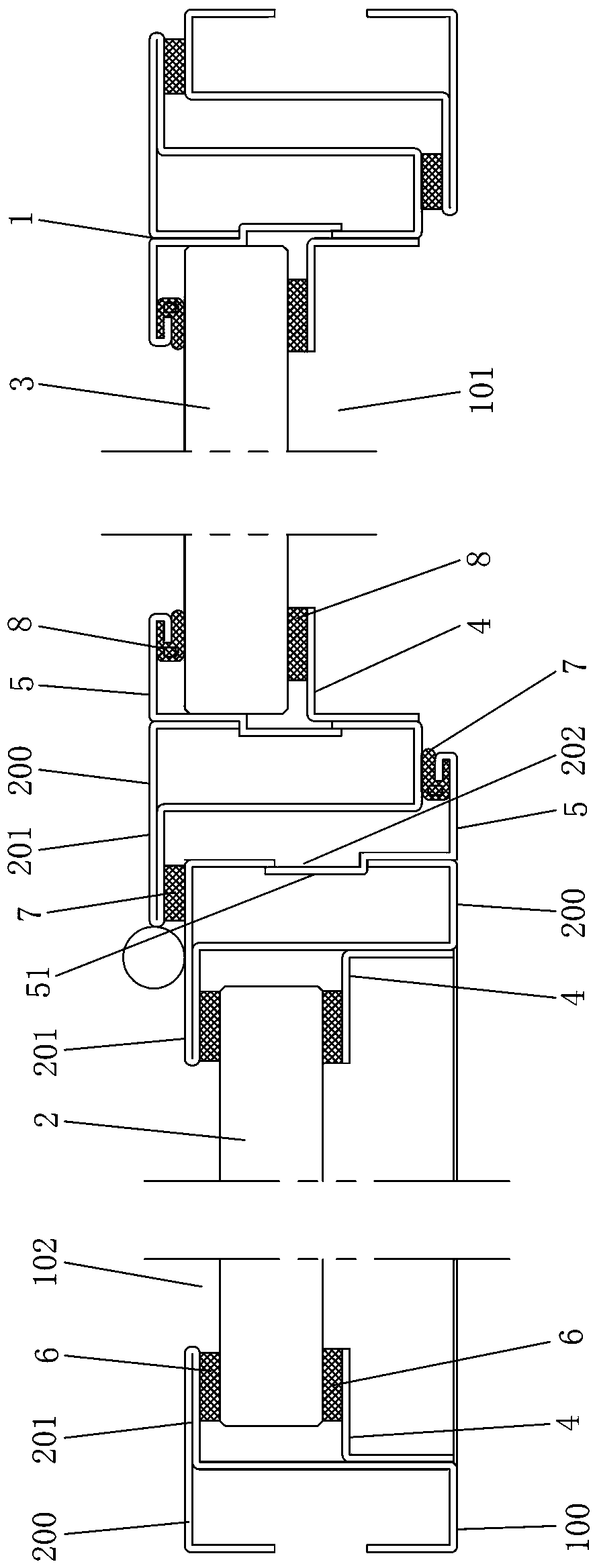

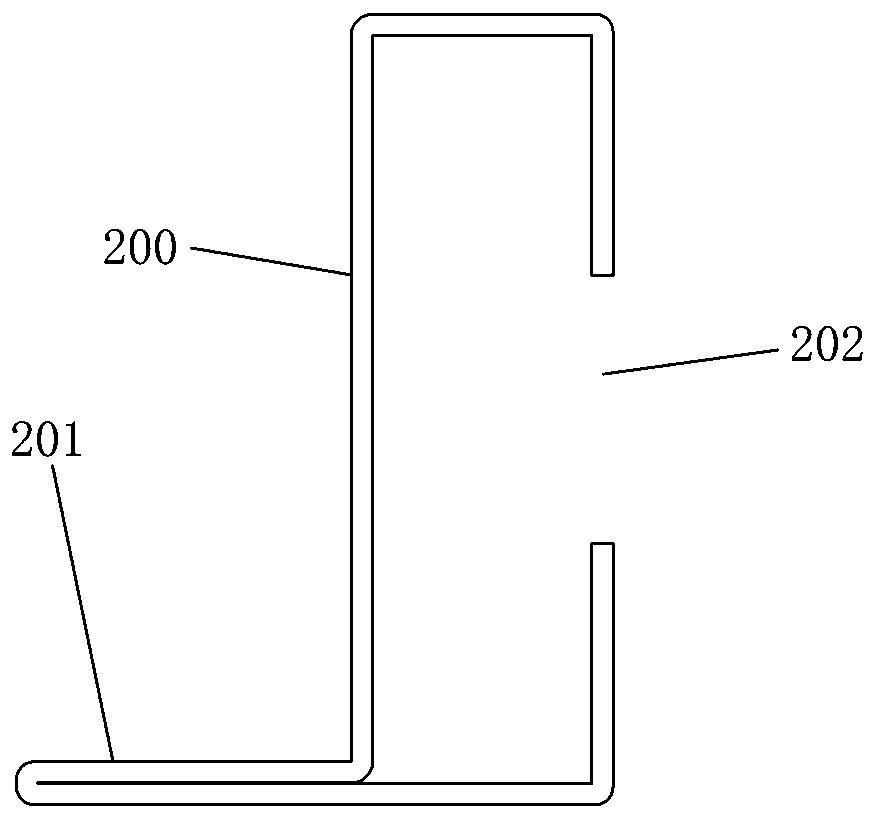

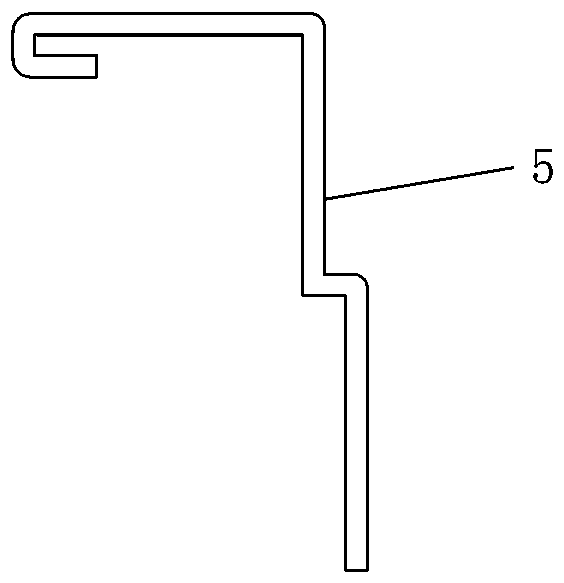

[0021] Such as Figure 1 to Figure 3 As shown, the splicing type door and window system of this embodiment includes a skeleton 100, the skeleton 100 has more than one fan frame 101 and more than one fixed frame 102, the window sashes 1 that can be opened are installed in the fan frame 101, and the second frame is installed in the fixed frame 102. A glass plate 2, the window sash 1 includes a frame body and a second glass plate 3 installed in the frame body, the frame body of the window sash 1 and the skeleton 100 are connected by a load-bearing beam 200, and one side of the load-bearing beam 200 is provided with a rib 201, the rib 201 of the load-bearing beam 200 connected to the frame of the sash 1 extends to the outside of the sash 1 and blocks the gap between the sash 1 and the frame 101 when the sash 1 is closed, and the load-bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com