A preparation device for integrated packaging adhesive film photovoltaic glass

A technology of encapsulating adhesive film and photovoltaic glass, which is applied in photovoltaic power generation, semiconductor devices, electrical components, etc., can solve the long-term or short-term reliability impact of components, increase the production cycle of crystalline silicon solar cell components, increase the repetitive operation of employees, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

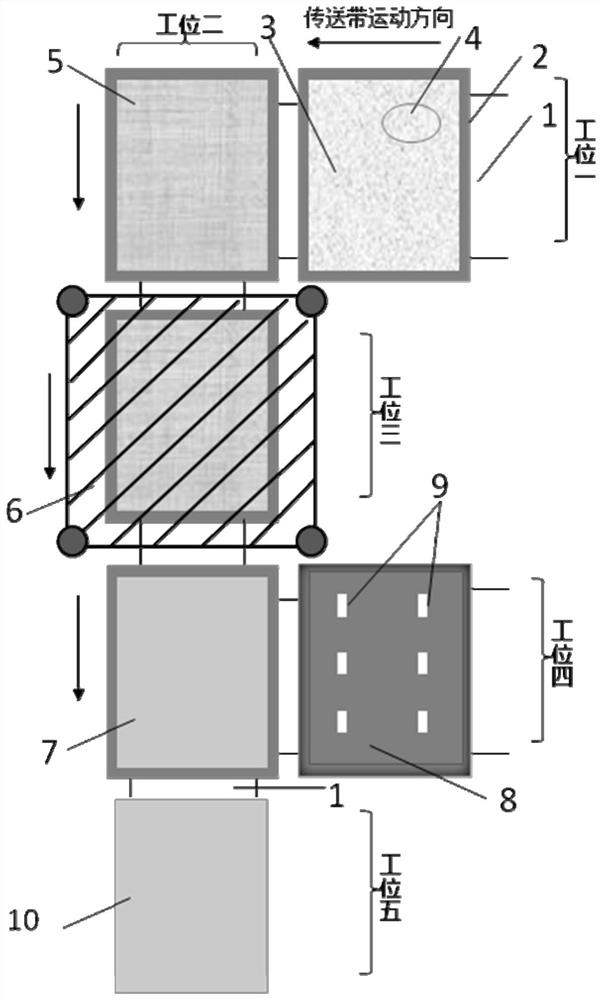

[0044] The preparation method of the integrated encapsulation adhesive film photovoltaic glass provided in this embodiment includes the following steps: selecting photovoltaic glass, laying an encapsulation adhesive film raw material on the photovoltaic glass, setting an anti-adhesive layer on the encapsulation adhesive film raw material, and then Using a flat vulcanizer, press at a preset temperature and pressure for a preset time and then remove the anti-adhesive layer to obtain an integrated packaged thin-film photovoltaic glass.

[0045] The packaging film raw material is the resin particles and additives disclosed in the patent CN 102115642 A, specifically the EVA packaging film raw material.

[0046] The preset temperature is 105° C., the preset pressure is 300 mbar, and the preset time is 3 minutes.

[0047] The laying amount of packaging film raw material is 420g / m 2 .

[0048] The anti-sticking cloth is Teflon high-temperature anti-sticking cloth.

Embodiment 2

[0050] The preparation method of the integrated encapsulation adhesive film photovoltaic glass provided in this embodiment includes the following steps: selecting photovoltaic glass, laying an encapsulation adhesive film raw material on the photovoltaic glass, setting an anti-adhesive layer on the encapsulation adhesive film raw material, and then Using a flat vulcanizer, press at a preset temperature and pressure for a preset time and then remove the anti-adhesive layer to obtain an integrated packaged thin-film photovoltaic glass.

[0051] The encapsulating film raw material can refer to the raw materials disclosed in CN 109705773 A and CN_108795124_A patents, specifically polyolefin POE.

[0052] The preset temperature is 120° C., the preset pressure is 400 mbar, and the preset time is 4 minutes.

[0053] The laying amount of encapsulation film raw material is 500g / m 2 .

[0054] The anti-sticking cloth is a special high-temperature anti-sticking cloth for commercially avai...

Embodiment 3

[0056] The preparation method of the integrated encapsulation adhesive film photovoltaic glass provided in this embodiment includes the following steps: selecting photovoltaic glass, laying an encapsulation adhesive film raw material on the photovoltaic glass, setting an anti-adhesive layer on the encapsulation adhesive film raw material, and then Using a flat vulcanizer, press at a preset temperature and pressure for a preset time and then remove the anti-adhesive layer to obtain an integrated packaged thin-film photovoltaic glass.

[0057] For Borealis Quentys polyolefin encapsulation film BPO8828F, the preset temperature is 145°C, the preset pressure is 700mbar, and the preset time is 3min.

[0058] The laying amount of encapsulation film raw material is 460g / m 2 .

[0059] The anti-adhesive layer is not bonded to the packaging film raw material, and the anti-adhesive layer is an anti-adhesive film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com