Quake-proof anti-noise passenger car floor

A passenger car floor and floor technology, which is applied to vehicle components, superstructure, superstructure sub-assembly, etc., can solve the problems of long-distance bus ride comfort, lack of floor sound-absorbing function design, and high noise on the bus floor, so as to improve comfort performance, reduce the overall noise, improve the effect of sound absorption and noise prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

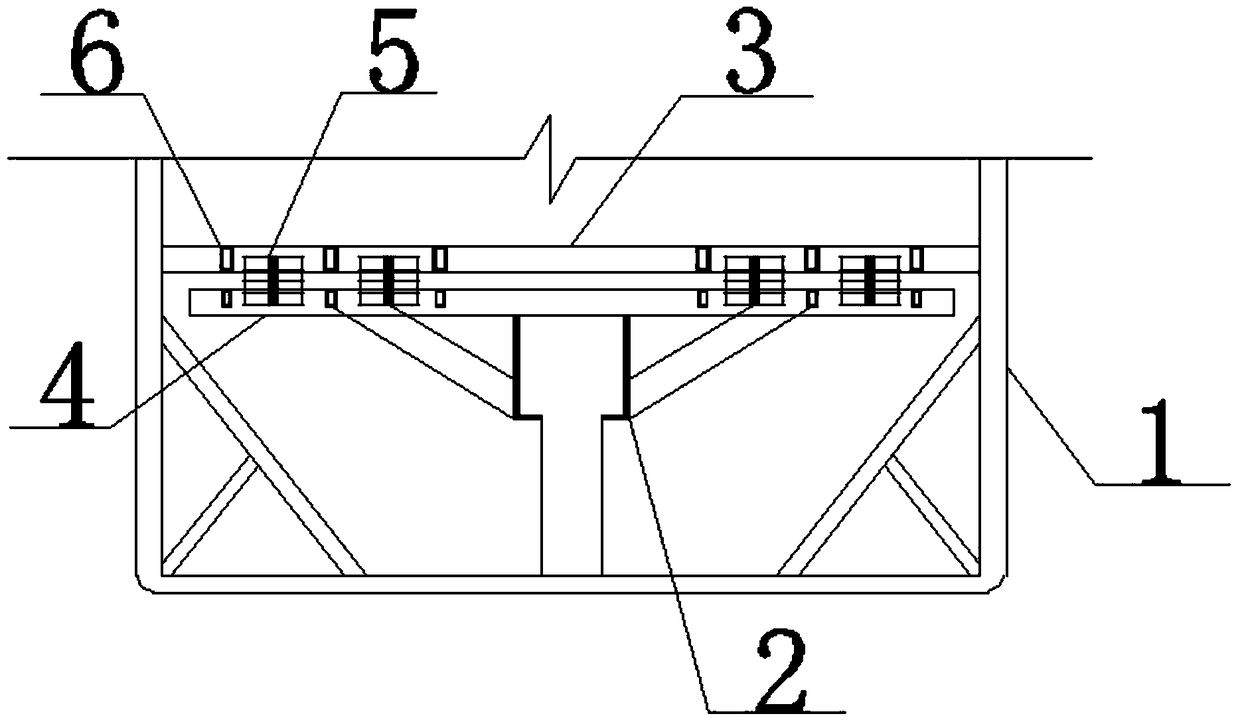

[0027] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 Shown, it has shown an embodiment of the present invention, the shockproof and noise-proof passenger car floor of the present invention, as figure 1 As shown, inside the passenger car compartment 1, the passenger car floor and the passenger car compartment 1 are supported and connected by the bracket 2. The bracket 2 is composed of a plurality of steel pipe brackets with triangular structures, forming a triangular structure with multiple supports, which strengthens the connection between the passenger car compartment 1 and the passenger car compartment 1. The firmness of the connection between the passenger car floors.

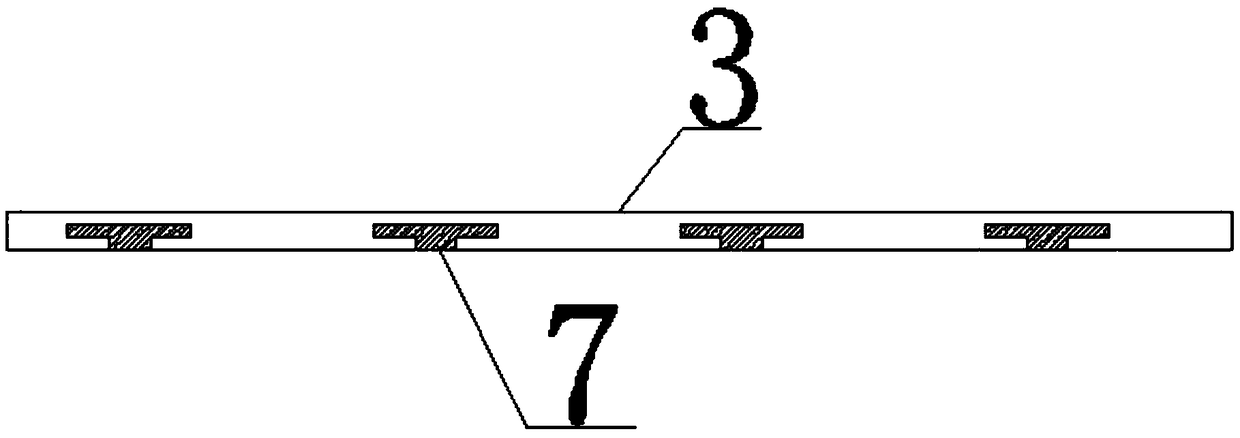

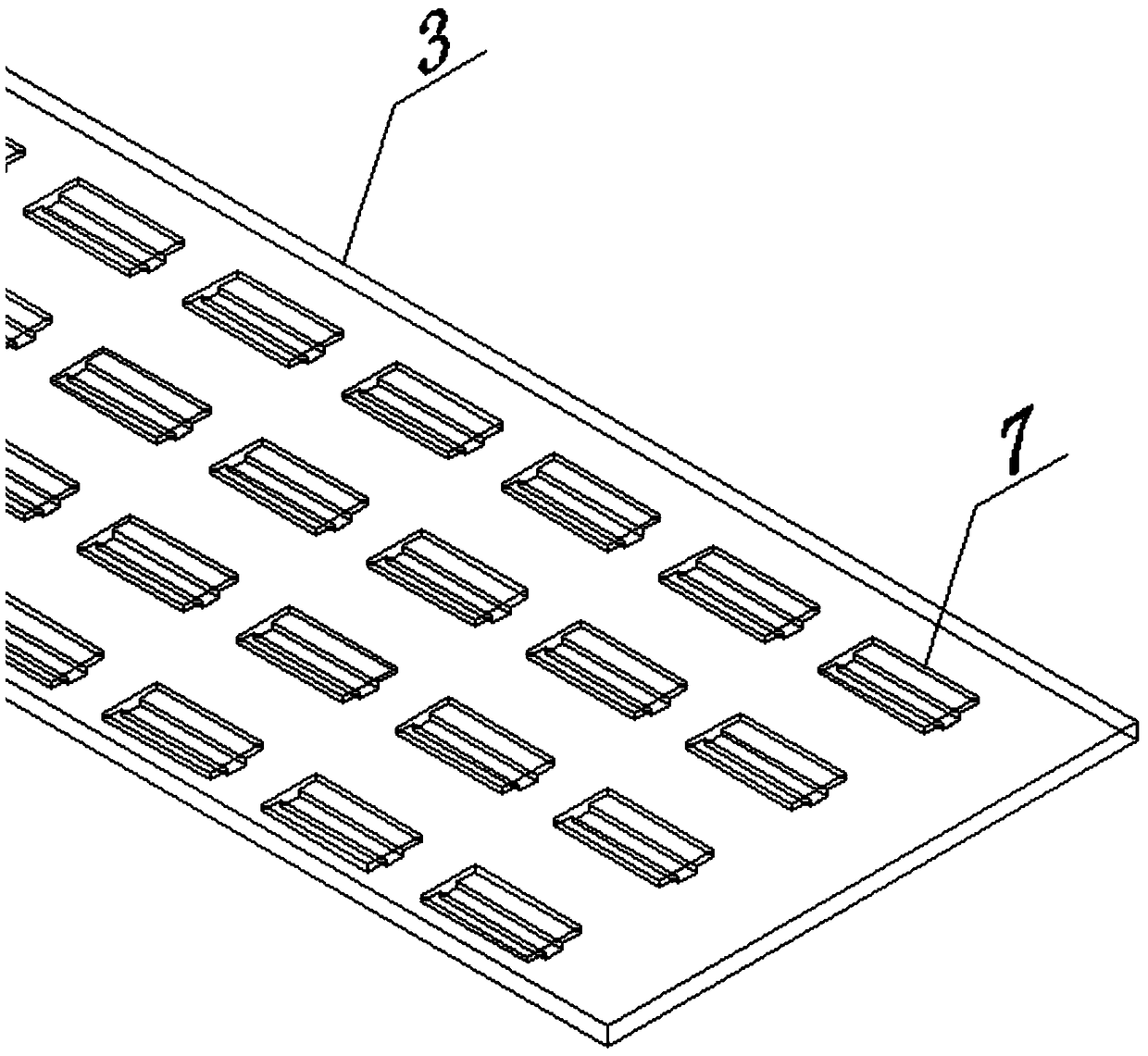

[0028] The above passenger car floor comprises two layers, respectively the upper floor 3 and the lower floor 4, the upper floor 3 and the lower floor 4 are connected by a connector 5, the connector 5 is made of rubber, while ensuring the connection strength, the rubber The connecting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com