Threshing engine

A technology of engine and casing, applied in the field of threshing engines, can solve the problems of shortening the service life of the engine, not having the anti-collision function, and the engine not having the anti-shock function, etc., and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

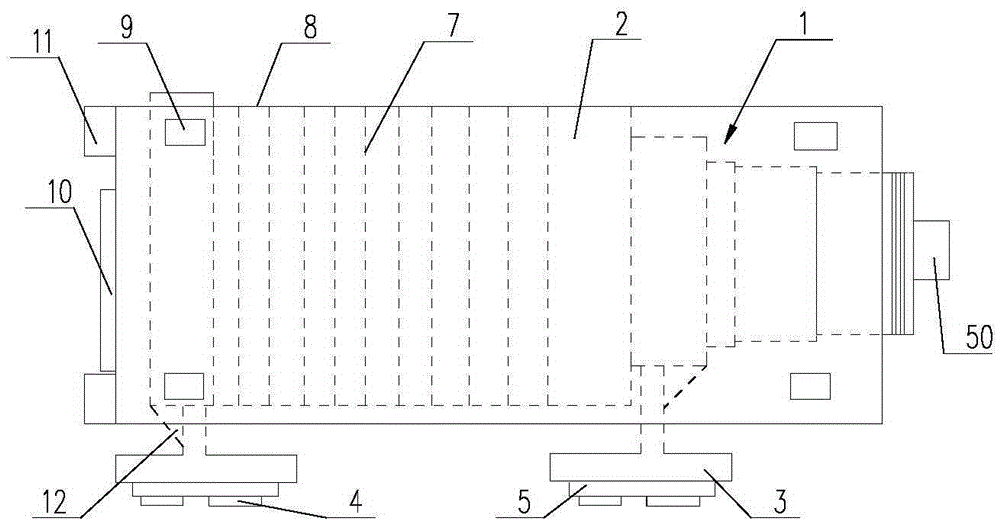

[0026] Such as Figure 1-Figure 4 Shown, a kind of engine for threshing, comprises engine 1 and engine case 2, and four supporting feet 3 are arranged on the bottom of engine case 2; Made of stainless steel.

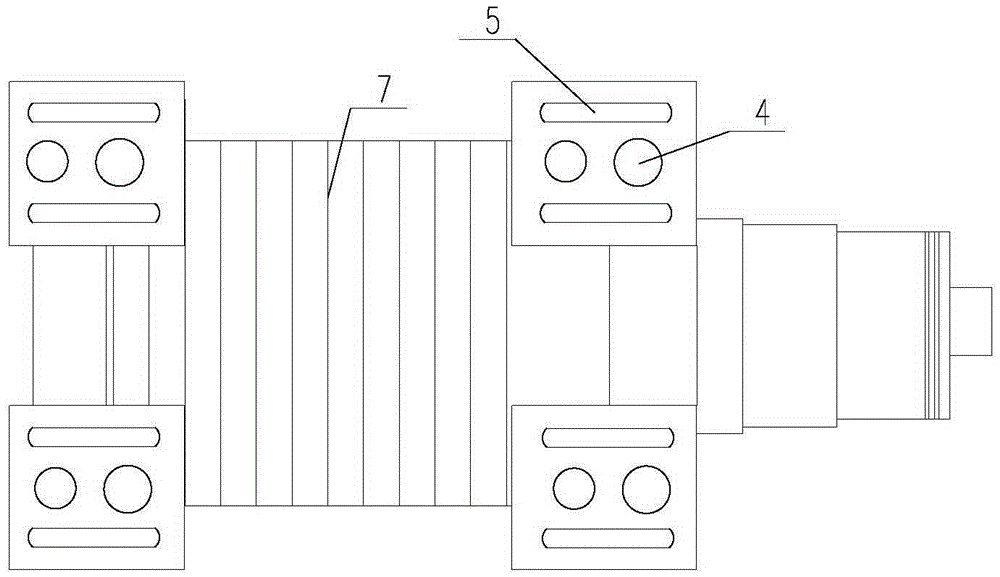

[0027] Each supporting foot 3 is provided with two mutually parallel elongated engine adjustment holes 5; each engine adjustment hole 5 protrudes downward;

[0028] The bottom of each supporting foot 3 is provided with two buffer pads 4, and the two buffer pads 4 on each supporting foot 3 are one large and one small.

[0029] The buffer pad 4 is arranged between the two engine adjustment holes 5, and the height of each buffer pad 4 is higher than the height of the engine adjustment hole 5;

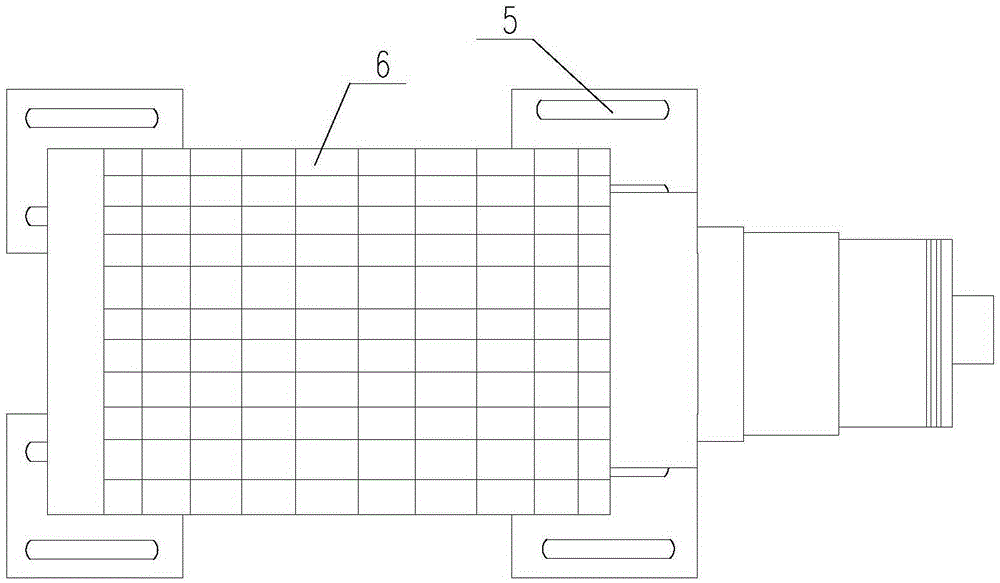

[0030] The top of the engine casing 2 is provided with a mesh-shaped heat dissipation net 6; the two sides, the rear end and the bottom of the engine casing 2 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com