Bamboo fiber and acrylic fiber blending air vortex spinning product and weaving method for same

A technology of acrylic fiber and vortex spinning, which is applied in the direction of textiles, papermaking, and yarn, and can solve the problems of poor pilling, hard vortex spinning, low strength of bamboo fiber, and poor wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solution of the present invention will be further described below through specific examples.

[0034] Spinning process:

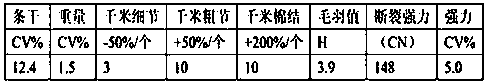

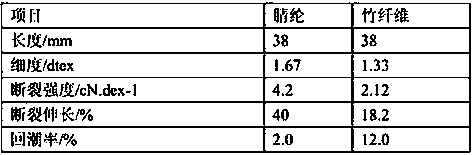

[0035] Table 1: Raw material performance indicators

[0036] 1. Process flow

[0037] ①Acrylic fiber: FA002 type grabbing machine → A006B type cotton mixing machine → FA106 type cotton opener → A092AST type cotton feeding machine → A076F type lapping machine → FA201B type carding machine → FA306A type drawing frame (acrylic fiber pre-drawing machine strip)

[0038] ② Bamboo fiber: FA002 type plucking machine → A006B type cotton mixing machine → FA106 type cotton opener → A092AST type cotton feeder → A076F type lapping machine → FA201B type carding machine

[0039] ①②}→FA306A draw frame (two channels)→TD8 autoleveler draw frame→Vortex870 vortex spinning machine

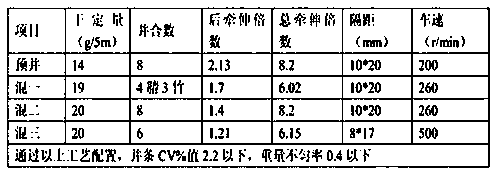

[0040] 2. Main spinning process parameters and production technical measures

[0041] Acrylic fibers have low moisture regain, fluffy fibers, easy entanglement during spinn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com