Process method for dry spinning of cotton and linen blended yarn

A process method, cotton and linen technology, applied in the directions of yarn, textile and papermaking, can solve the problems of low cost of raw linen, more linen skin and linen, inaccurate blending ratio of linen, etc. Highlight and improve the effect of fabric quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

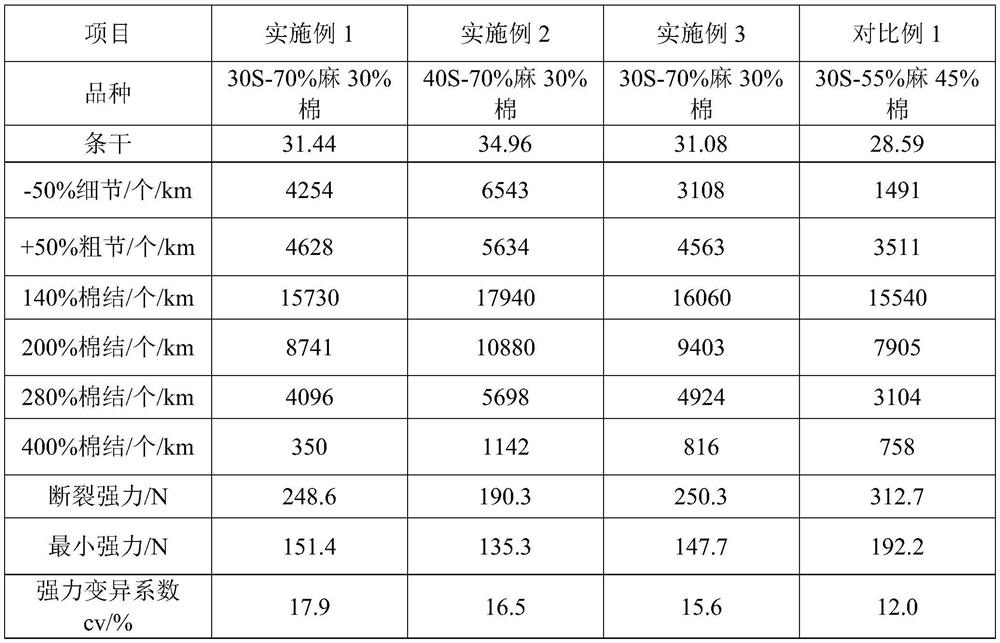

Examples

Embodiment 1

[0039] A kind of technical method of dry-spinning cotton-linen blended spinning, is prepared by the following steps:

[0040] (1) Combing hemp strips: Bleaching and degumming the raw hemp, kneading the hemp once, maintaining health for 3 days (according to 100kg flax mixed with 3kg health-care solution + 11kg water), kneading the hemp twice, cutting to 110mm, and then loosening three times, The raw hemp is spun into carded hemp sliver with a carding machine, and the determined quantity is 28g / 5m, and the health-preserving liquid is commercially available;

[0041] (2) Pure blending of hemp strips: combine hemp strips and hemp strips, and formulate a quantitative value of 22g / 5m to make the quantitative stability, optimize the quantitative ratio for the blending ratio, control the total draft ratio to 6 times, and the draft ratio in the rear area is 1.5 times, the drawing speed is 200m / min;

[0042] (3) Mixing and merging: the hemp slivers after pure merging are mixed with pur...

Embodiment 2

[0048] A kind of technical method of dry-spinning cotton-linen blended spinning, is prepared by the following steps:

[0049](1) Combing hemp strips: Bleaching and degumming the raw hemp, kneading the hemp once, maintaining health for 3 days (according to 100kg flax mixed with 3kg health-care solution + 11kg water), kneading the hemp twice, cutting to 110mm, and then loosening three times, The raw hemp is spun into carded hemp sliver with a carding machine, and the determined quantity is 28g / 5m, and the health-preserving liquid is commercially available;

[0050] (2) Pure blending of hemp strips: combine hemp strips and hemp strips, and formulate a quantitative value of 22g / 5m to make the quantitative stability, optimize the quantitative ratio for the blending ratio, control the total draft ratio to 6 times, and the draft ratio in the rear area is 1.5 times, the drawing speed is 180m / min;

[0051] (3) Mixing and merging: the hemp slivers after pure merging are mixed with pure...

Embodiment 3

[0057] A kind of technical method of dry-spinning cotton-linen blended spinning, is prepared by the following steps:

[0058] (1) Combing hemp strips: Bleaching and degumming the raw hemp, kneading the hemp once, keeping in good health for 5 days (according to 100kg of flax mixed with 3kg of health care solution + 11kg of water), kneading the hemp twice, cutting to 110mm, and then opening 3 times, The raw hemp is spun into carded hemp sliver with a carding machine, and the determined quantity is 28g / 5m, and the health-preserving liquid is commercially available;

[0059] (2) Pure blending of hemp strips: combine hemp strips and hemp strips, and formulate a quantitative value of 22g / 5m to make the quantitative stability, optimize the quantitative ratio for the blending ratio, control the total draft ratio to 6 times, and the draft ratio in the rear area is 1.5 times, the drawing speed is 200m / min;

[0060] (3) Mixing and merging: the hemp slivers after pure merging are mixed w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com