Automatic inflating airbag for petroleum pipeline overhauling

A technology for automatic inflation and petroleum pipelines, applied in the direction of pipe components, engine components, pipes/pipe joints/fittings, etc., can solve problems such as heavy workload, failure to meet actual application requirements, leakage, rupture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

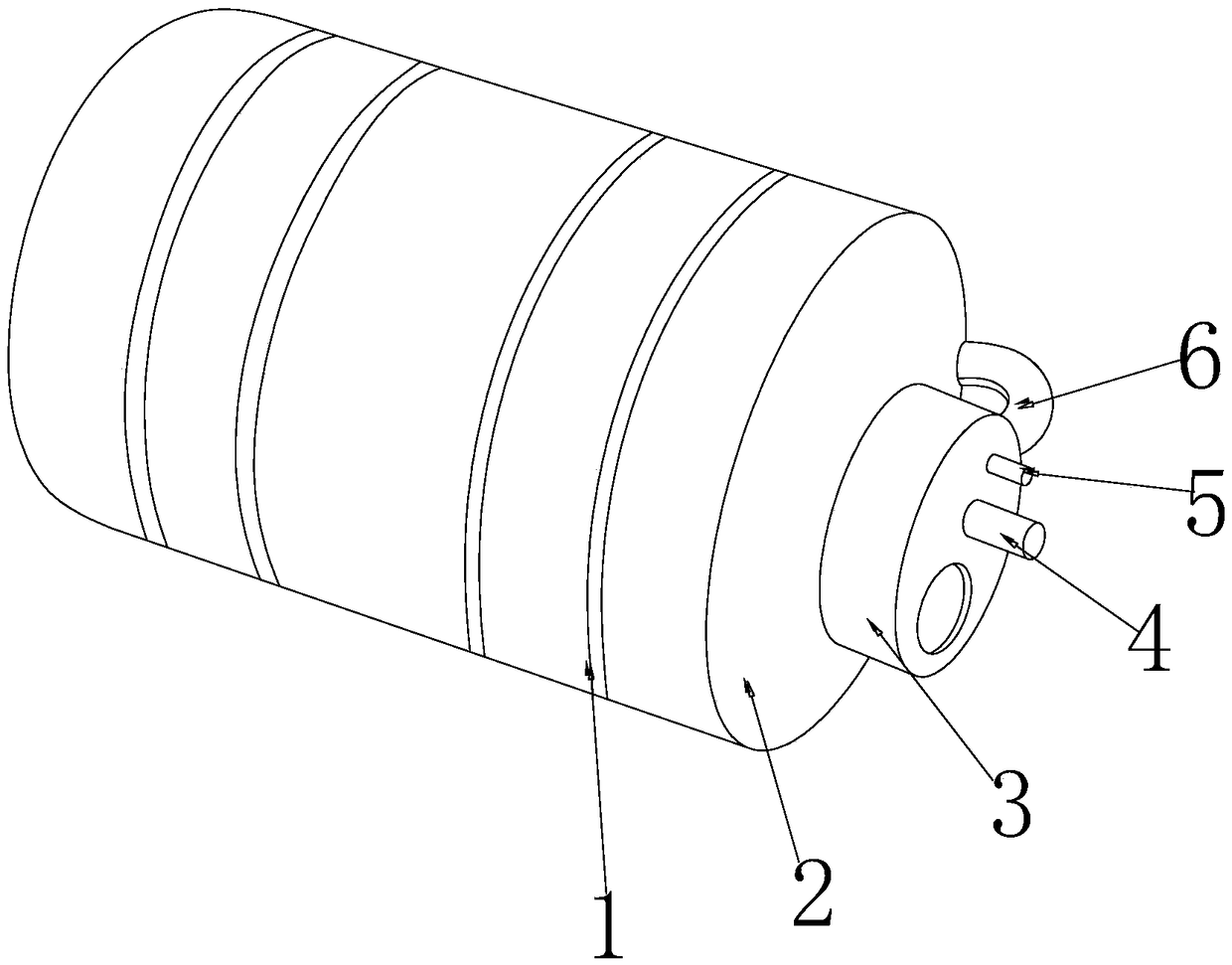

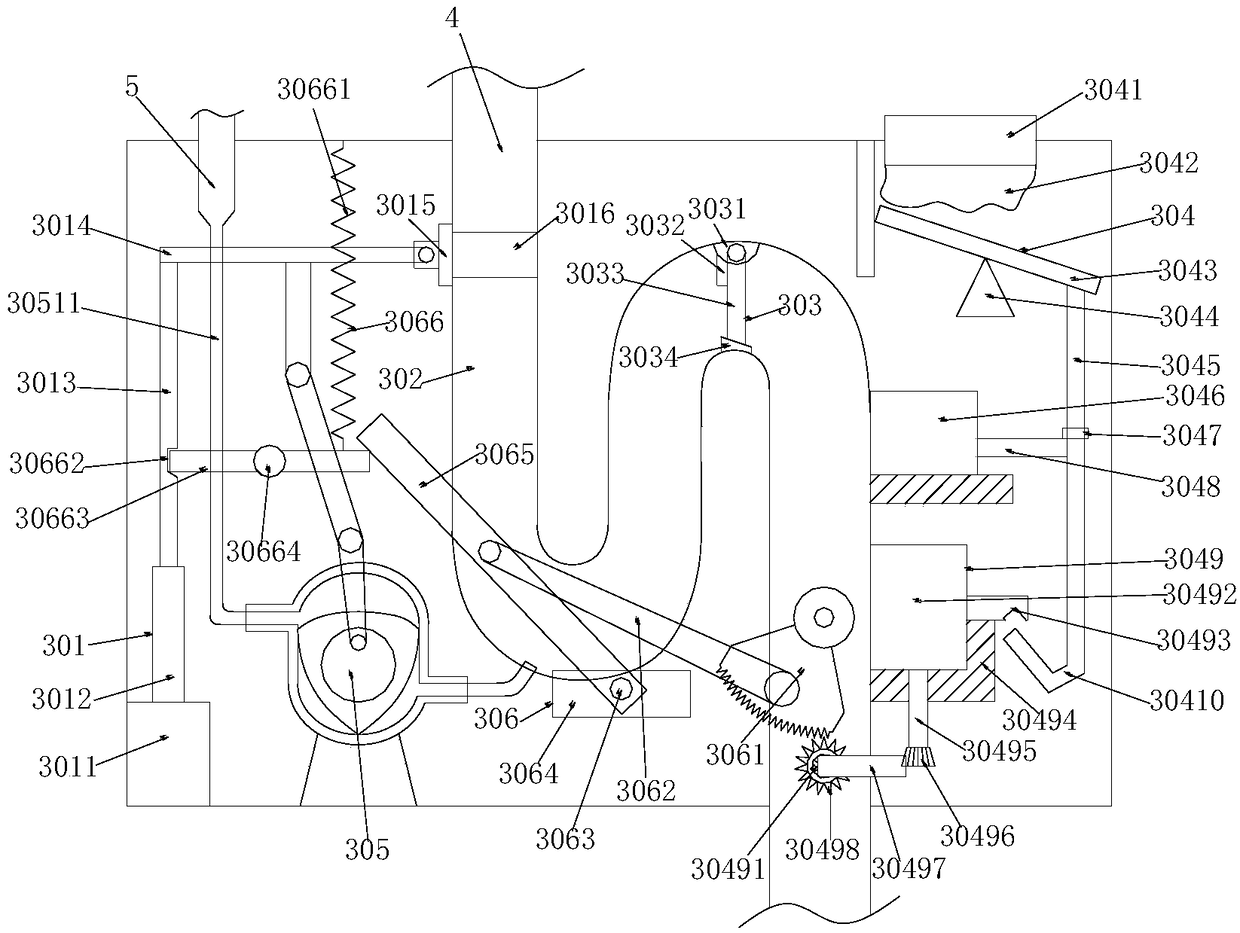

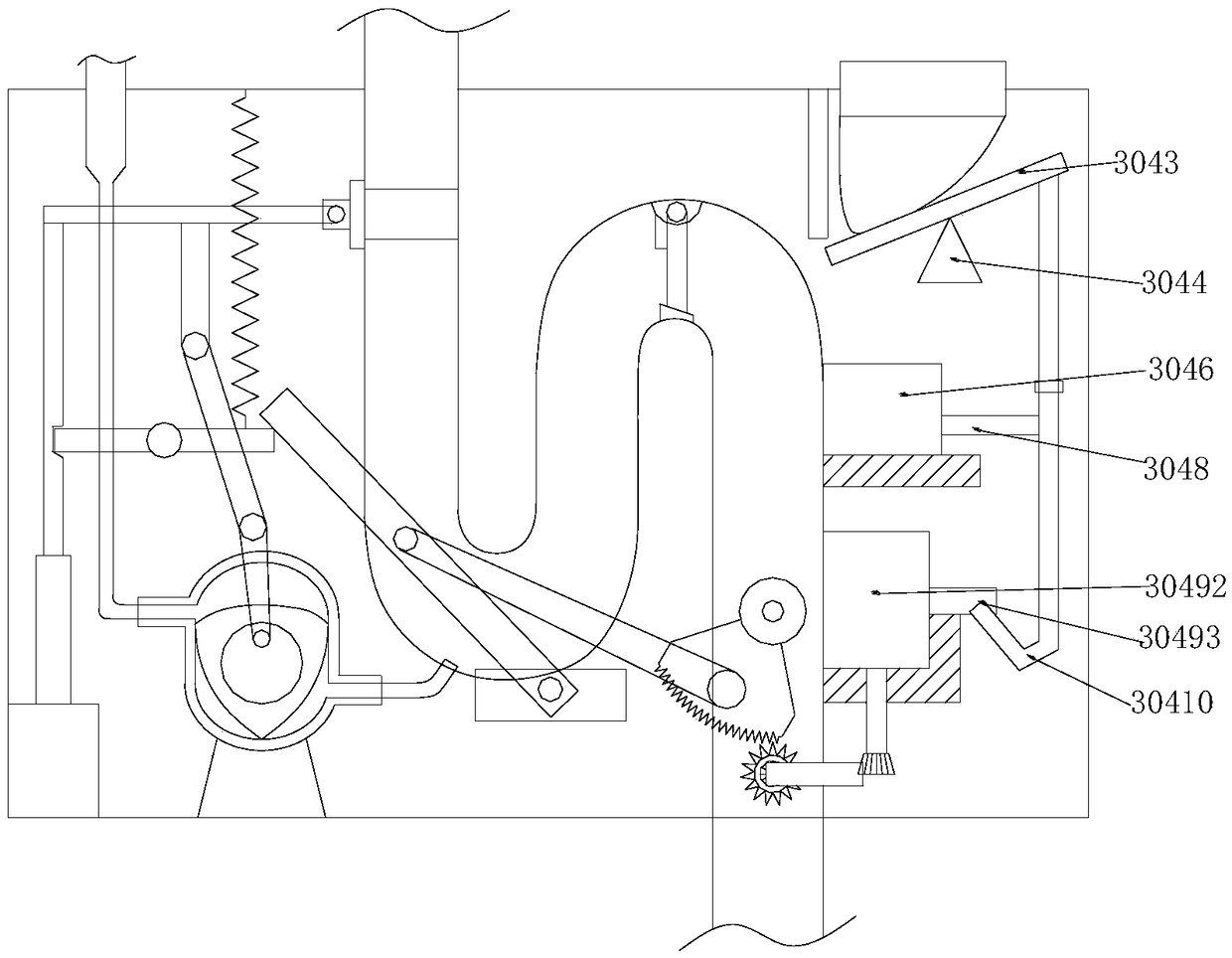

[0027] see Figure 1-Figure 6 , the present invention provides an automatic inflatable air bag for petroleum pipeline maintenance, its structure includes a friction ring 1, a casing 2, an automatic inflation device 3, a main air intake pipe 4, an auxiliary air intake pipe 5, and a tether ring 6, and the friction ring 1 is provided with Two or more are distributed equidistantly on the surface of the shell 2, the shell 2 and the friction ring 1 are set up as an integral structure, the automatic inflation device 3 is arranged on the shell 2 and communicates with the inner cavity of the shell 2, the said The end of the automatic inflation device 3 away from the shell 2 is fixedly provided with a main air intake pipe 4 and an auxiliary air intake pipe 5. The main air intake pipe 4 and the auxiliary air intake pipe 5 are all communicated with the automatic inflation device 3, and the described tether ring 6 The same end installed on the shell 2 with the automatic inflation device 3;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com