Automatic tire inflation device

An automatic inflating and tire technology, applied in measuring devices, optical devices, transportation and packaging, etc., can solve problems such as integration of inflatable and blanking, inability to realize tire feeding and automatic inflation detection, and time-consuming and labor-intensive inflation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

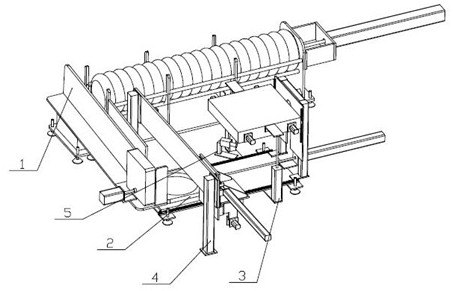

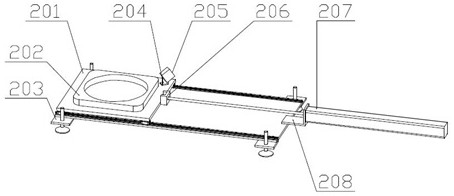

[0030] Example: such as figure 1 ,Such as figure 2 ,Such as image 3 ,Such as Figure 4 ,Such as Figure 5 ,Such as Figure 6 Shown is a tire automatic inflation device. Automatic feeding device 1, tire transport device 2, automatic inflation device 3, pneumatic tire unloading device 4, camera automatic detection device 5;

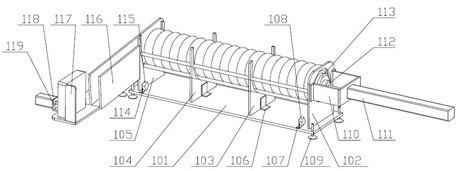

[0031] The specific structure of automatic feeding device 1 is as follows: figure 2As shown, the frame bottom plate 101, the frame front side plate 102, the frame middle side plate 103, the frame auxiliary side plate 104, the frame rear side plate 105, the fixed bracket 106, the full material sensor bracket 107, the full material sensor 108. Equipment feet 109, feed propulsion cylinder bracket 110, feed propulsion cylinder 111, feed propulsion cylinder connection block 112, tire propulsion block 113, material shortage sensor bracket 114, material shortage sensor 115, tire inclined conveying track 116, Tire baffle 117, feeding propulsion cylinder 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com