A self-filling gas extraction device

A self-filling and self-filling technology, which is applied in the direction of variable-capacity pump components, liquid variable-capacity machinery, pump components, etc., can solve the problems of ear washing balls, small double balls, easy to lose, easy to leak, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

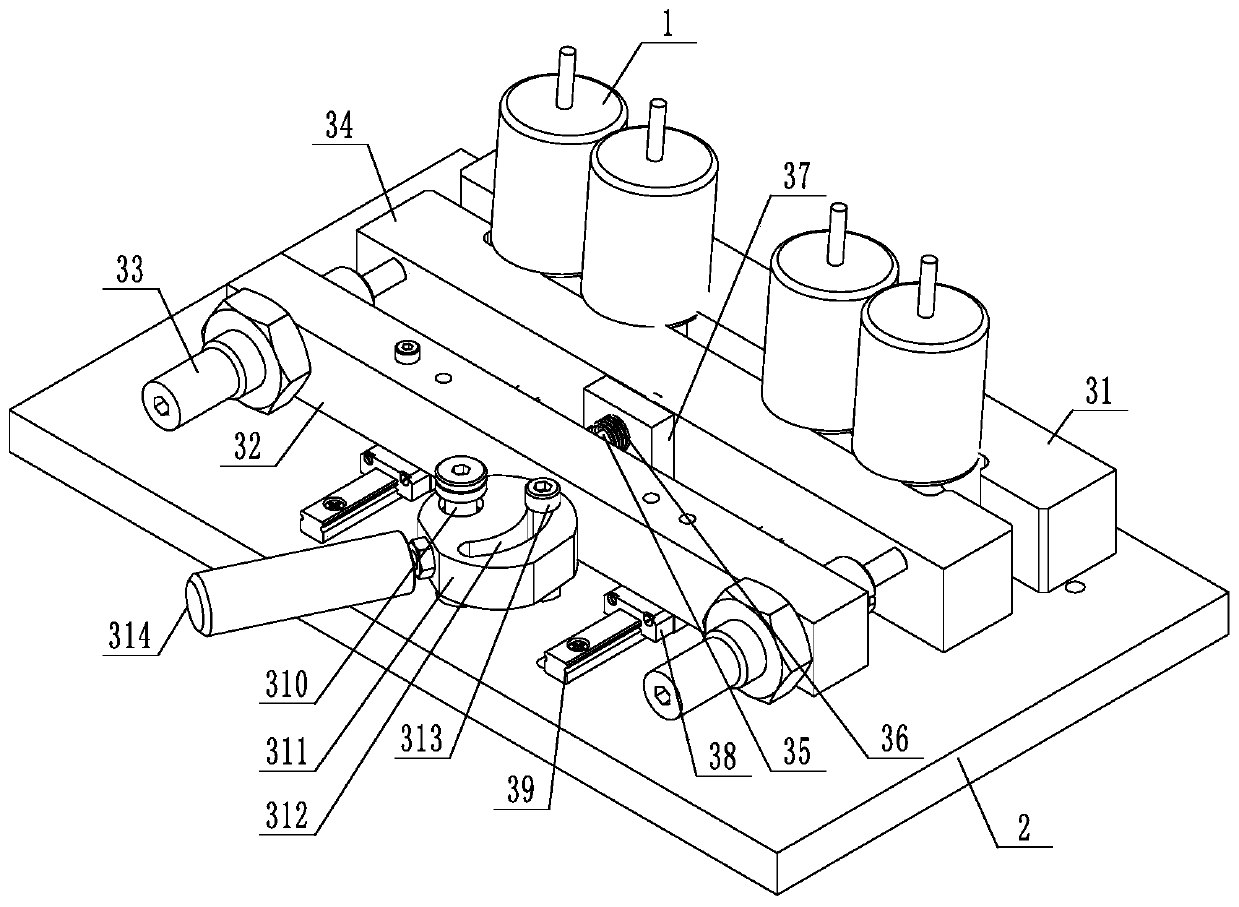

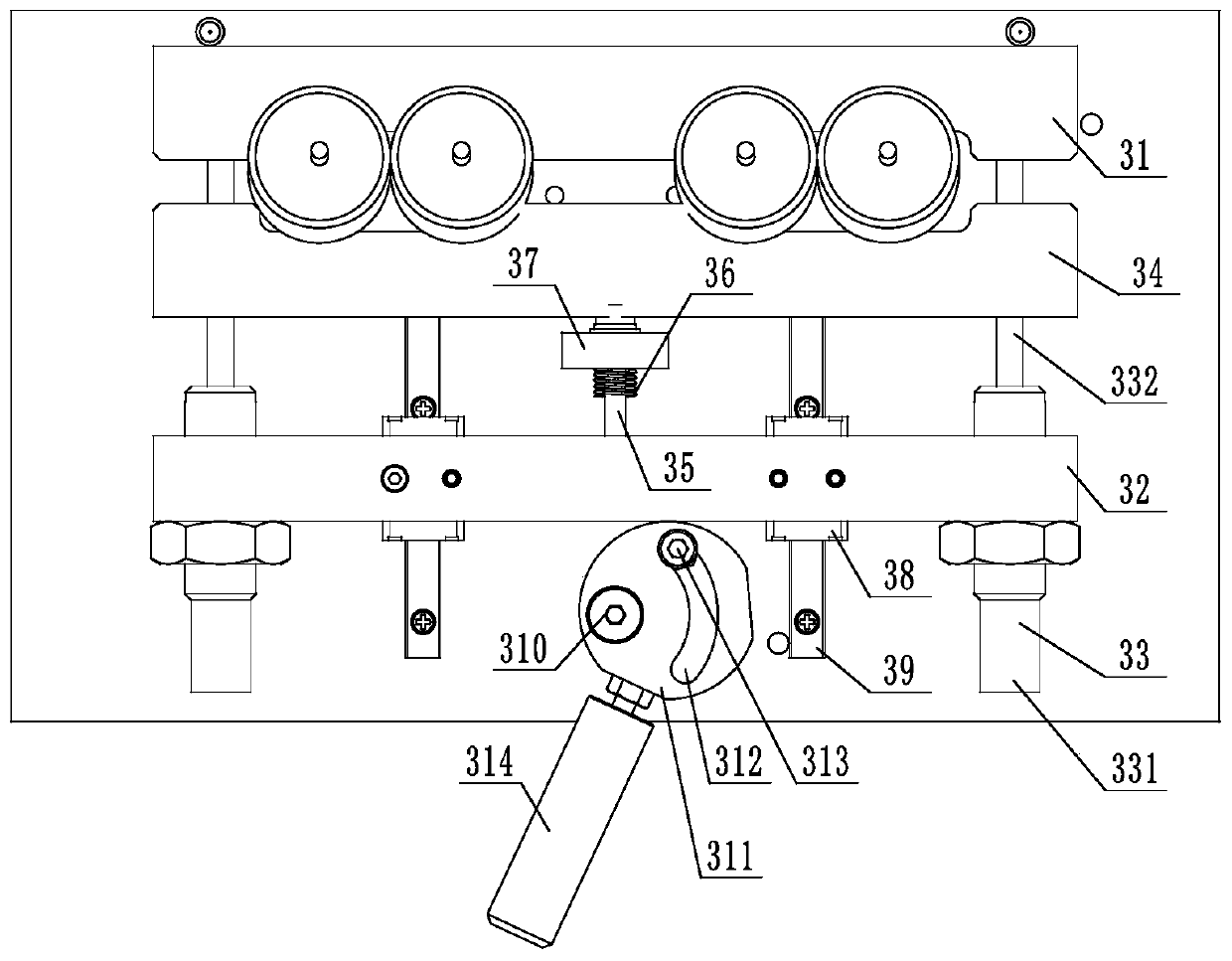

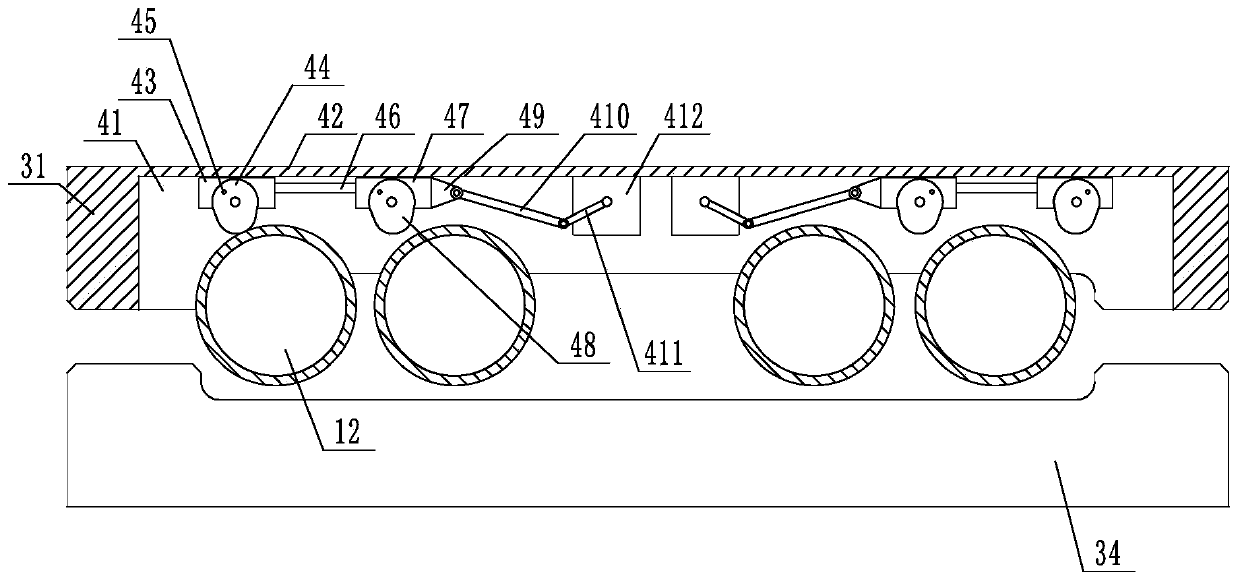

[0031] Such as Figure 1 to Figure 5 As shown, a self-inflating gas extraction device includes an inflatable bag 1, and the inflatable bag includes a bag body 14 and an inflation mechanism 12 connected by a hose 13,

[0032] The bag body 14 is made of aluminum foil, and the back side of the bag body 14 is provided with an air outlet pipe 15 . An air intake pipe 11 is connected to the inflatable mechanism, and a front check valve 16 is arranged in the air intake pipe. It can flow out of the bag from the outlet pipe. The air inlet pipe and the air outlet pipe can be closed with clips to ensure that the gas collected inside does not leak.

[0033] The inflation mechanism can spring up by itself, and the inflation mechanism can be a hollow rubber ball.

[0034] The working method is to bring the self-filling gas collection bag to the sampling site, use the clip to clamp the air bag outlet pipe, and press the inflation mechanism repeatedly. The field gas enters the inflation mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com