True triaxial seepage test device under action of surrounding rock or soil

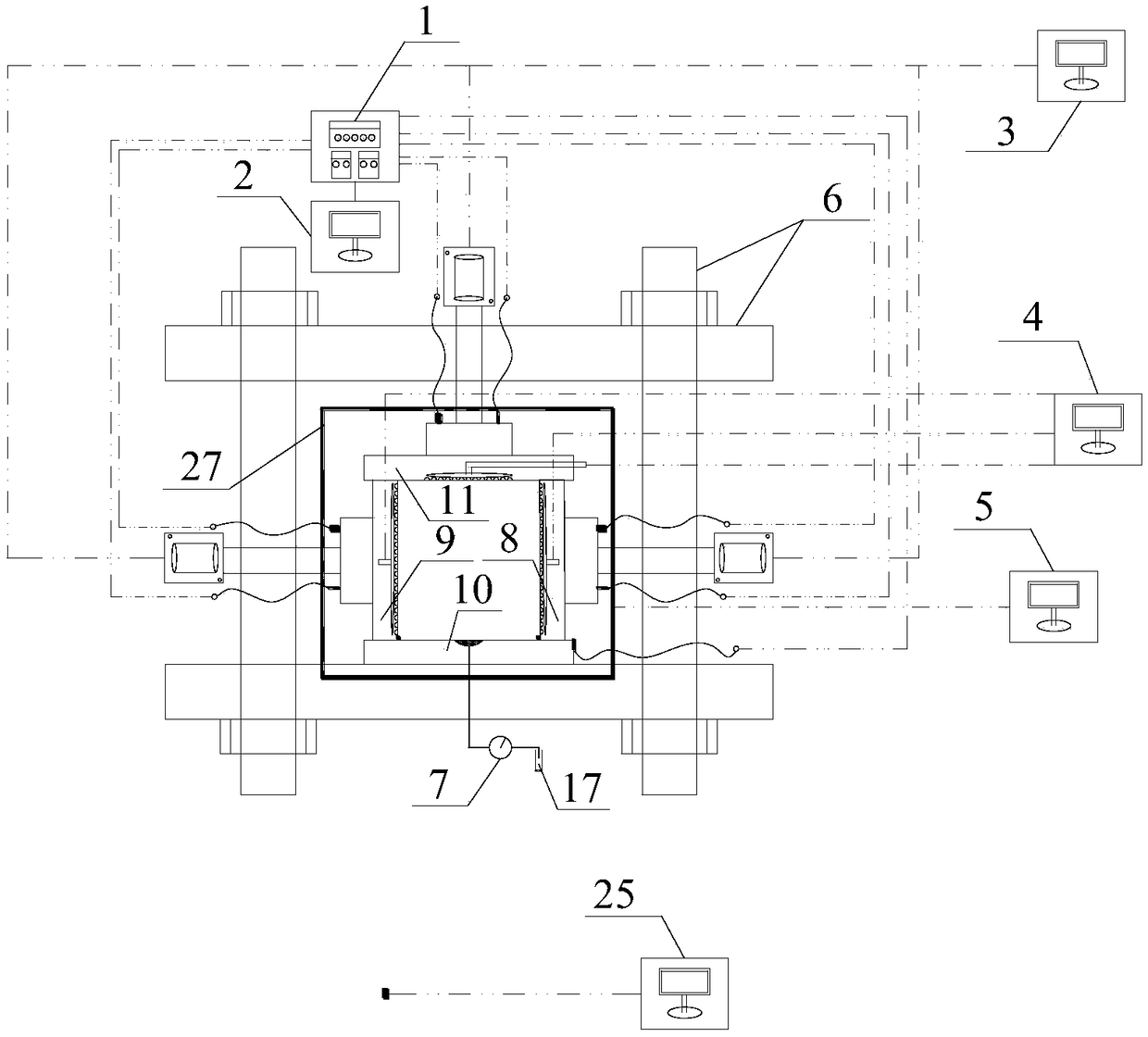

A test device, true triaxial technology, applied in measuring devices, using stable tension/pressure to test material strength, instruments, etc., can solve the problems of not considering the influence of underground structures and failing to reflect the stress of underground structures, etc. achieve the effect of ensuring safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0086] Example 1

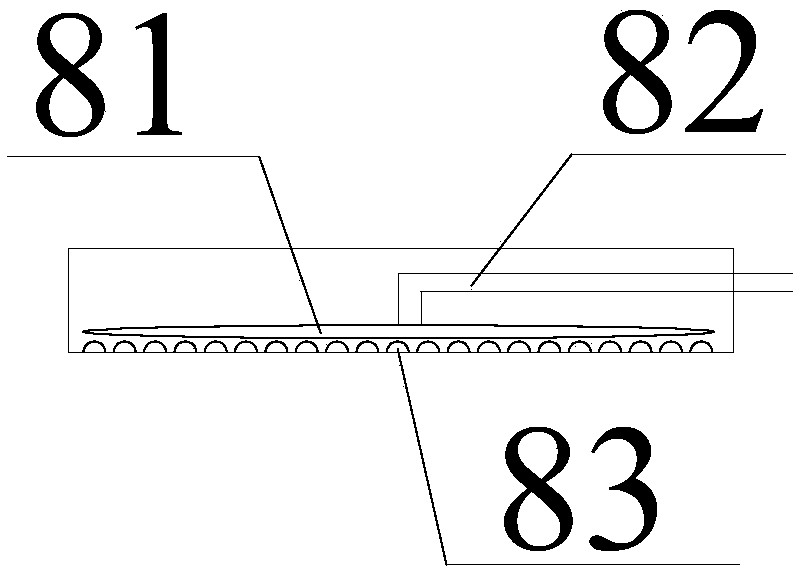

[0087] Since the prototype of the coal mine shaft is very large, only similar model theory can be used for model tests. During the working process of the shaft, there is groundwater seepage only in the circumferential direction, and there is no groundwater seepage at the upper and lower ends. Therefore, the servo seepage loading system 4 only controls the left side during the test. The water flow rate and water pressure of the seepage inlet conduit 82 of the right, front and rear pressure-bearing end plates, and the seepage control assembly of the upper pressure-bearing end plate 10 are temporarily disabled. Specific steps are as follows:

[0088] (1) Model making

[0089] Use similar theories to pour the model shaft wall and prepare appropriate similar materials to simulate the physical and mechanical properties of the surrounding rock or soil 20, and then use surrounding rock or soil 20 to tightly wrap the shaft wall in the center. The thickness of the surroundi...

Example Embodiment

[0099] Example 2

[0100] The underground structure is usually a concrete structure, so the prismatic concrete specimen 19 is used for the test. Depending on the situation, the prismatic concrete specimen 19 and the surrounding rock or soil 20 can be tested for lateral seepage mechanics, or the prismatic concrete specimen 19 and Axial seepage mechanics test of surrounding rock or soil 20, and a combination of the two, wherein the lateral seepage mechanics test method of prismatic concrete specimen 19 and surrounding rock or soil 20 is similar to the above-mentioned scheme 1, except that the object to be tested is different.

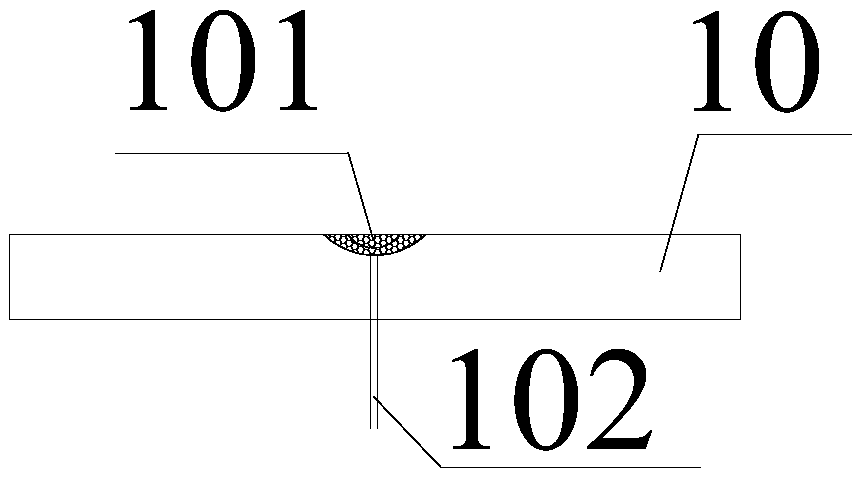

[0101] The test procedures of the axial seepage mechanics of the prism concrete specimen 19 and the surrounding rock or soil 20 are as follows:

[0102] (1) Model making

[0103] Pour the prismatic concrete specimen 19, then use the surrounding rock or soil 20 at the project site, or replace the surrounding rock or soil 20 with similar materials, and wrap the pri...

Example Embodiment

[0113] Example 3

[0114] The prismatic concrete specimen 19 and the surrounding rock or soil 20 both axially and laterally seepage mechanics test steps are basically the same as those in Example 2, except that in step (3), the servo seepage loading system 4 controls the left and The seepage water inlet conduit 82 of the right, front, and rear pressure-bearing end plates and the seepage water inlet conduit 112 of the upper pressure-bearing end plate apply water flow and corresponding water pressure to form a stable seepage around the test piece.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com