Optical fiber wire managing equipment

A technology of cable management equipment and optical fiber, applied in the direction of fiber mechanical structure, etc., can solve the problems of consuming a lot of energy, clearly distinguishing pigtails, and affecting work efficiency, so as to achieve straight and beautiful wiring, improve work efficiency, and facilitate operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

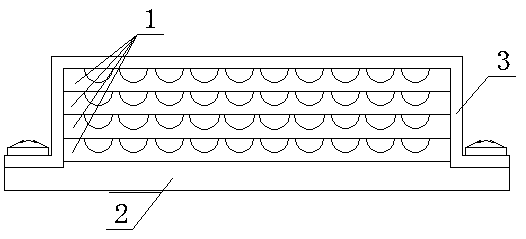

[0023] Below in conjunction with the accompanying drawings, the implementation of the fiber optic cable management device will be further described in detail (see Figure 1-8 ):

[0024] An optical fiber cable management device, which is composed of a pigtail placement plate 1, a fixed frame cover 2, and a base 3; The anastomotic cover is equipped with a fixed frame cover 2, and the fixed frame cover 2 is fixed on the base 3 through bolts;

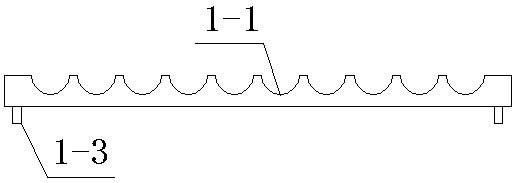

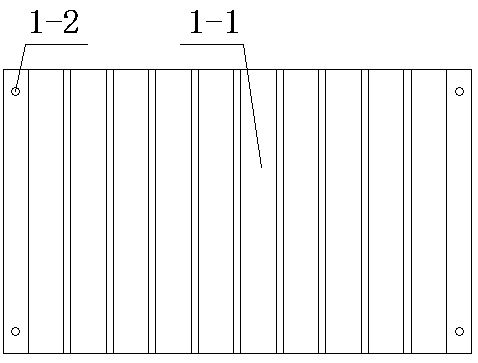

[0025] There are multiple pigtail fiber placement boards 1, and multiple grooves 1-1 are made parallel and evenly distributed on the surface of the pigtail fiber placement board 1. The four corners of the pigtail fiber placement board 1 are symmetrically made with pits A1-2, and the pigtail fiber placement boards The four corners on the back of board 1 are symmetrically made with inserting protrusions A1-3, which correspond to the recesses A1-2 (see Figure 1~3 );

[0026] The fixed frame cover 2 is made up of top plate 2-1, vertical pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com