Device for adjusting circular degree of non-metallic ring

An adjustment device, a non-metallic technology, applied in the field of non-metallic ring roundness adjustment devices, can solve the problems of insufficient machining allowance, difficulty in controlling the roundness of blanks, and economic losses of enterprises, so as to avoid waste of raw materials, facilitate adjustment, and improve The effect of production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

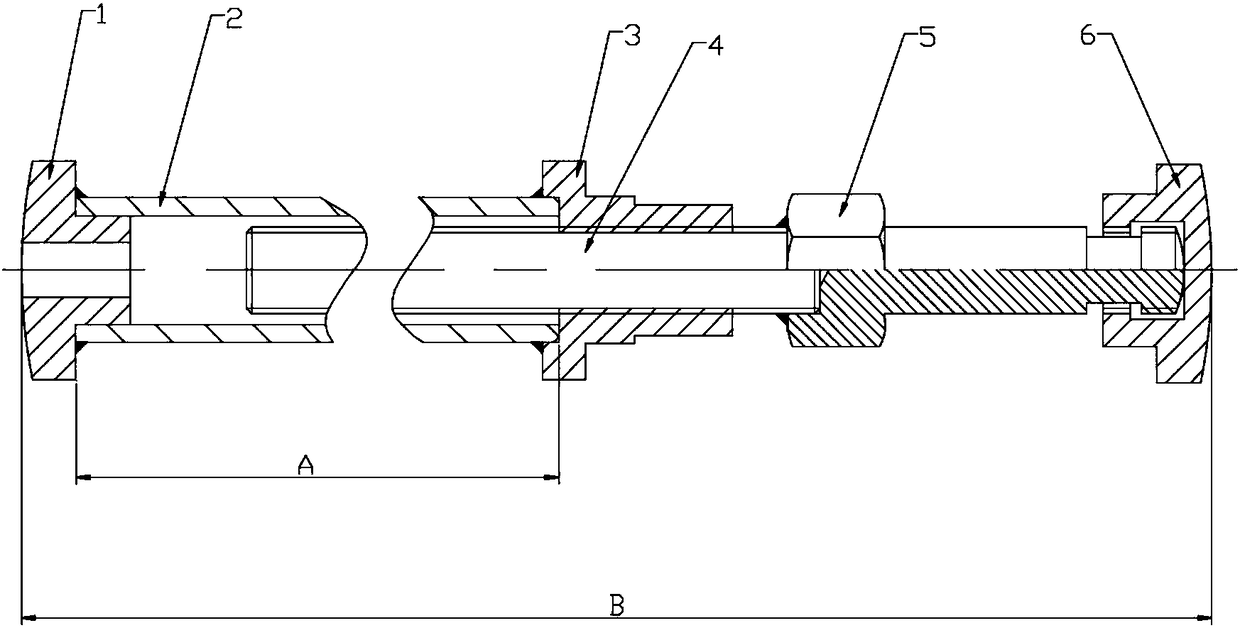

[0024] Such as figure 1 As shown, a non-metallic ring roundness adjustment device, the adjustment device includes a round tube sleeve and an adjustment rod, the adjustment rod extends into the round tube sleeve and is set movably in the round tube sleeve, the round tube sleeve and the adjustment rod There is a support block at each end, and the outer surface of the support block is arc-shaped; adjust the length of the adjustment rod extending into the tube sleeve so that the length of the adjustment device is at a minimum, place the adjustment device in the inner hole of the non-metallic ring, adjust The movement of the adjusting rod in the circular tube sleeve increases the length of the adjusting device until the circular tube sleeve and the support block at the end of the adjusting rod contact the surface of the inner hole of the non-metallic ring, thereby completing the roundness adjustment of the non-metallic ring.

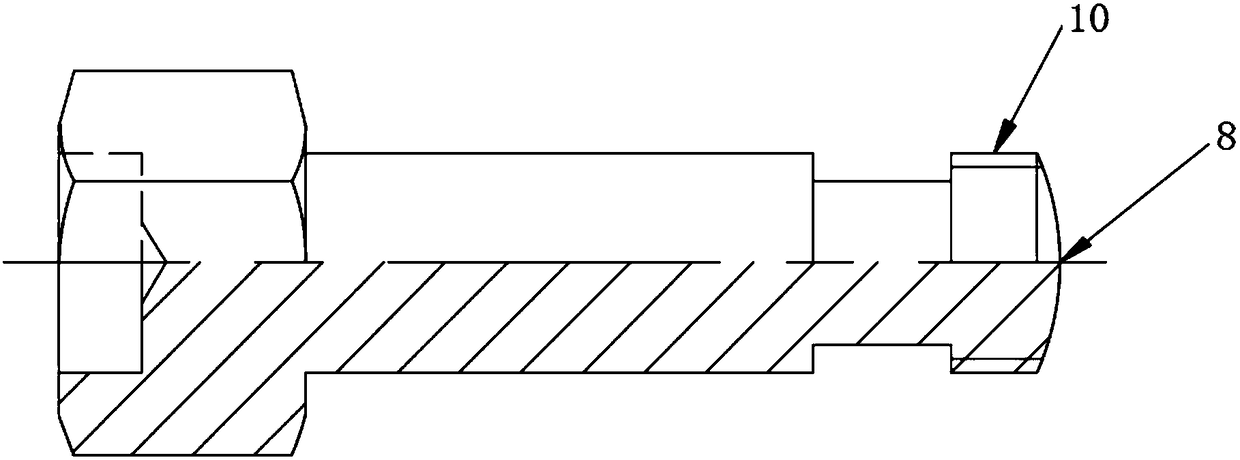

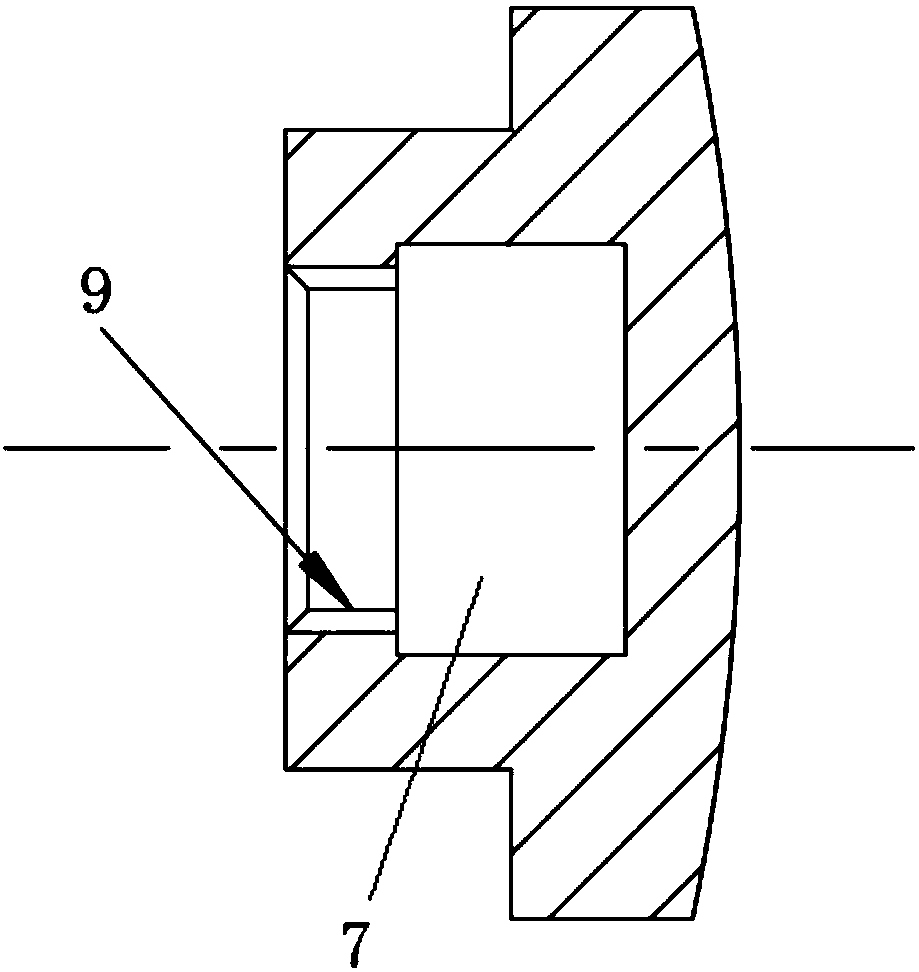

[0025] The round tube includes a sleeve body 2 and an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com