An adsorption crawler crawler mechanism and a wall-climbing robot having the same

A wall-climbing robot and adsorption-type technology, applied in the field of wall-climbing robots, can solve the problems of the crawling mechanism being unable to maintain the wall surface area and friction force, reducing the adsorption force, and unable to crawl through continuously, so as to reduce the overall damage risk and maintenance. cost, improving obstacle clearance height, good social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

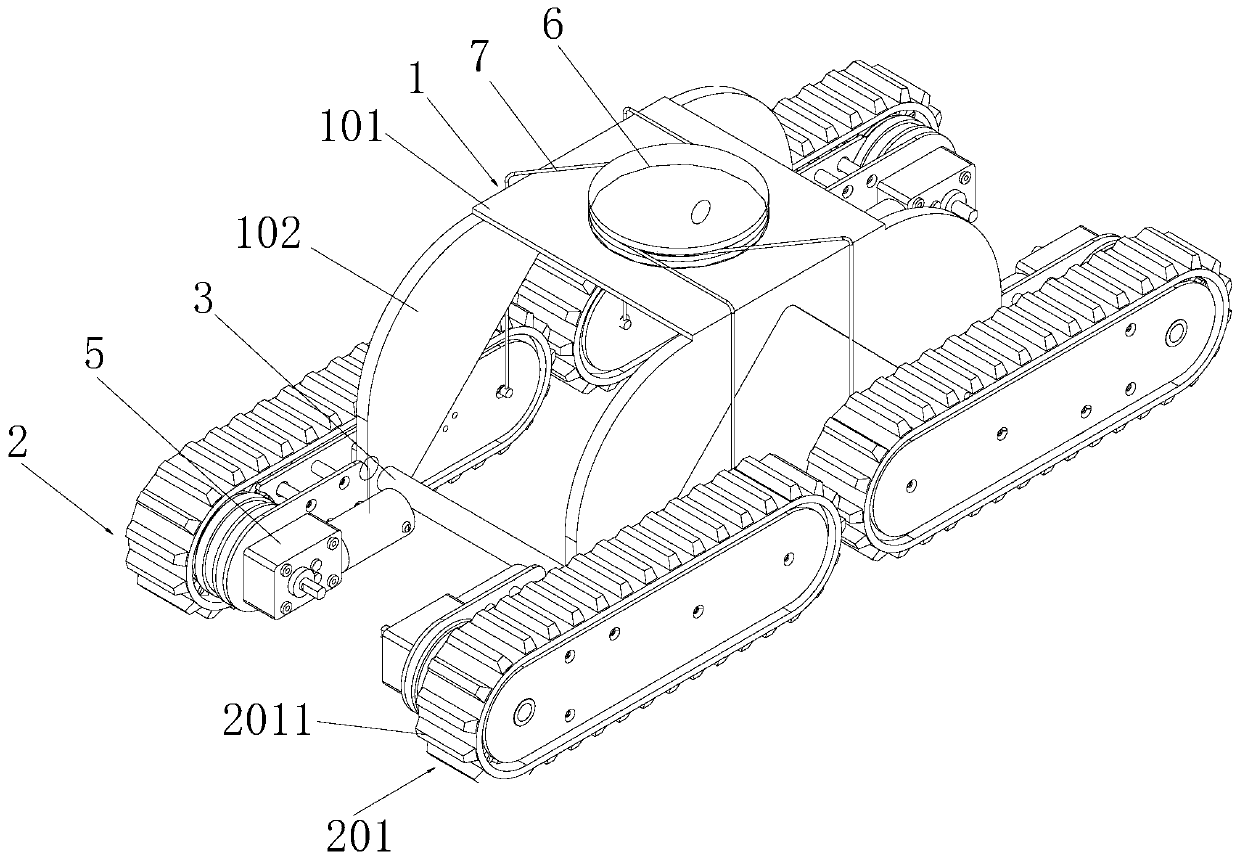

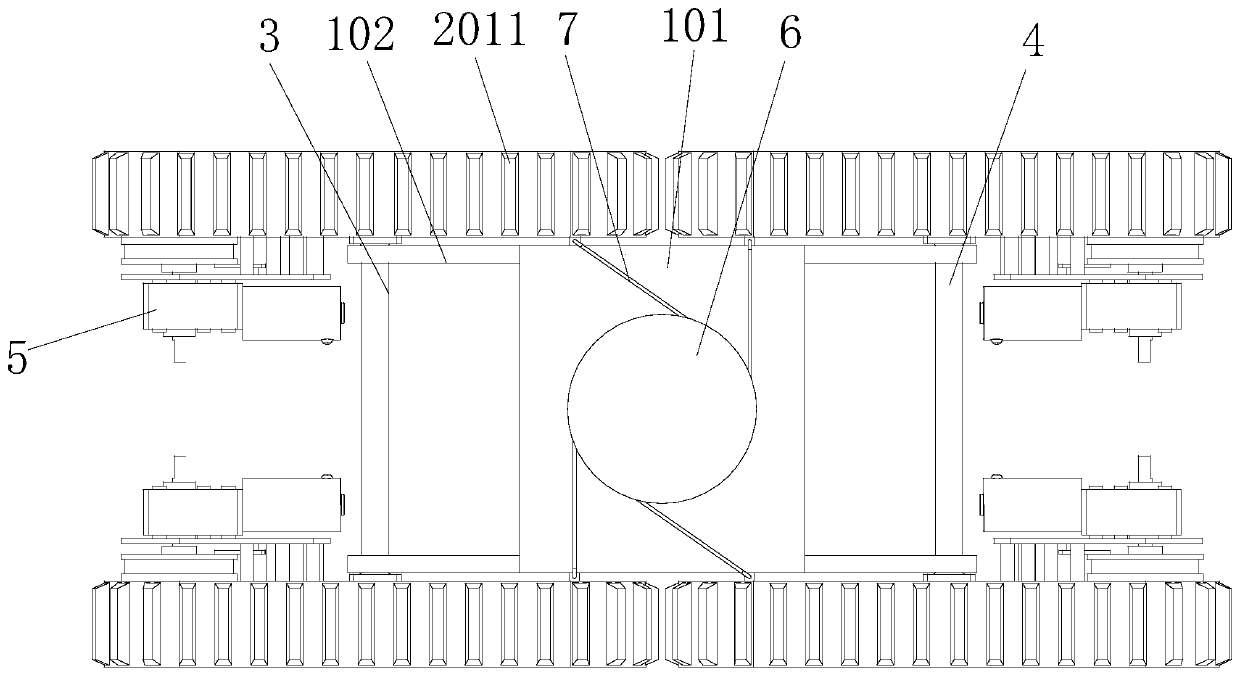

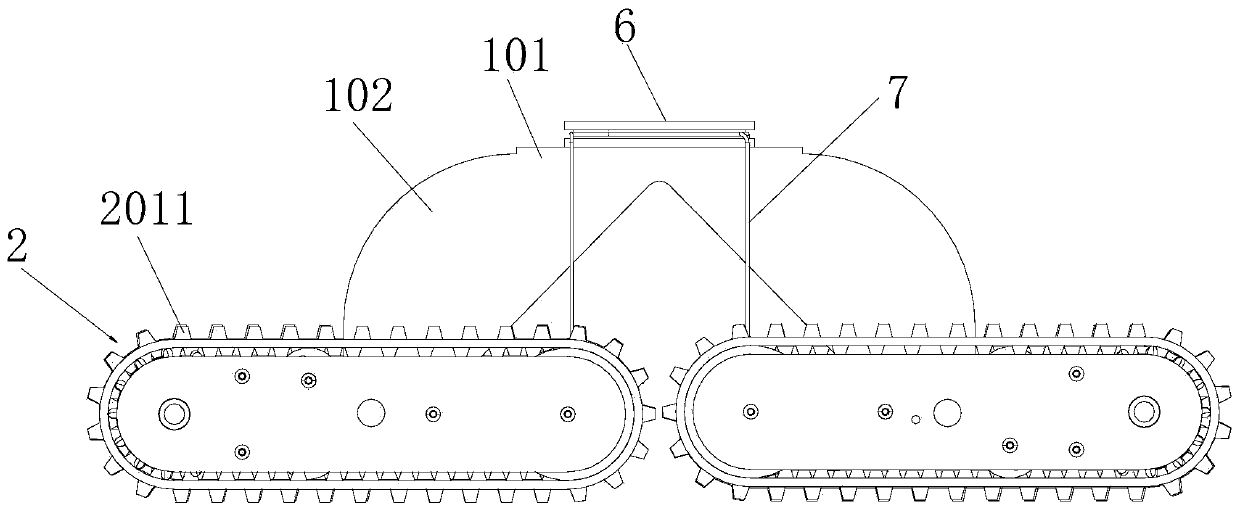

[0047] Such as Figure 1 to Figure 21 As shown, an adsorption crawler crawler mechanism at least includes a first connection chassis 1 and a crawler wheel assembly 2 arranged at the bottom of the first connection chassis 1. Adsorption crawler belt 201, the adsorption crawler belt 201 is provided with a plurality of magnets 2011 at regular intervals along its circumferential direction.

[0048] As one of the implementations, the crawling mechanism is a two-stage crawling mechanism, and the two-stage crawling mechanism includes a first connection chassis 1 and a track wheel assembly 2 arranged at the bottom of the first connection chassis 1. There are four track wheel assemblies 2, Four crawler wheel assemblies 2 are respectively arranged at four corners of the bottom of the first connecting chassis 1 . The front side of the first connection chassis 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com