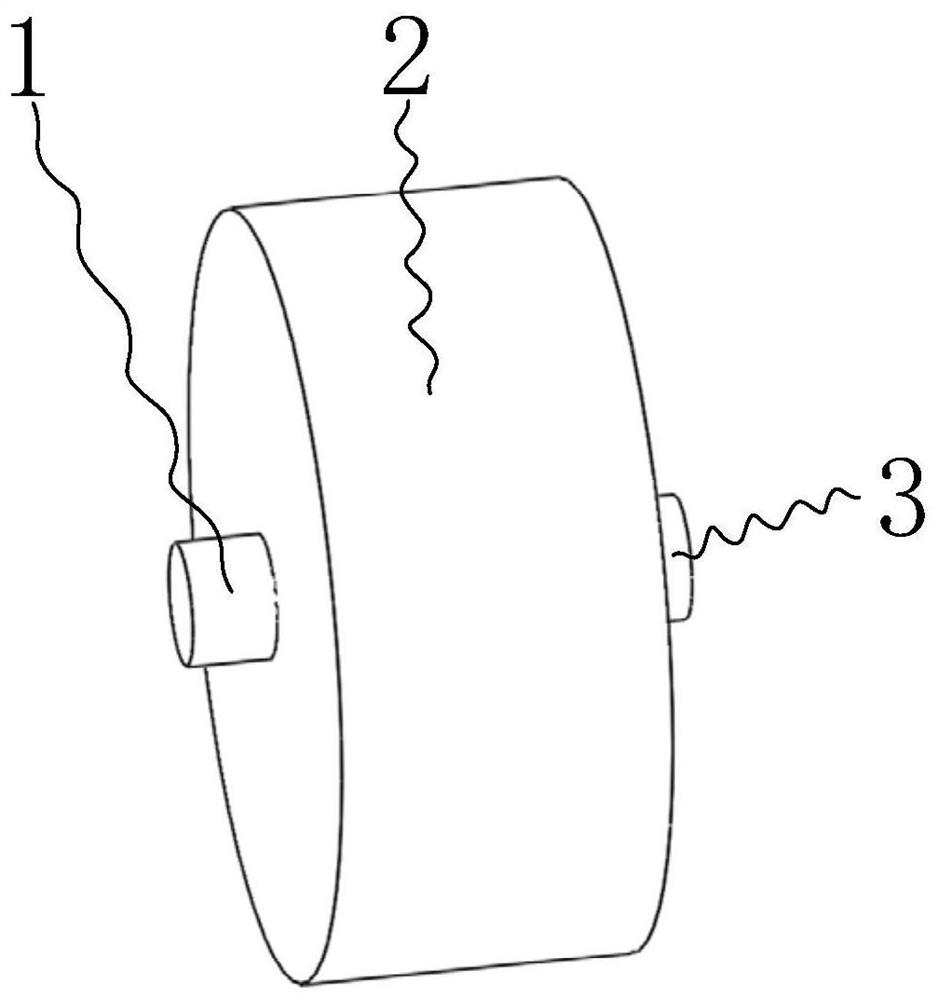

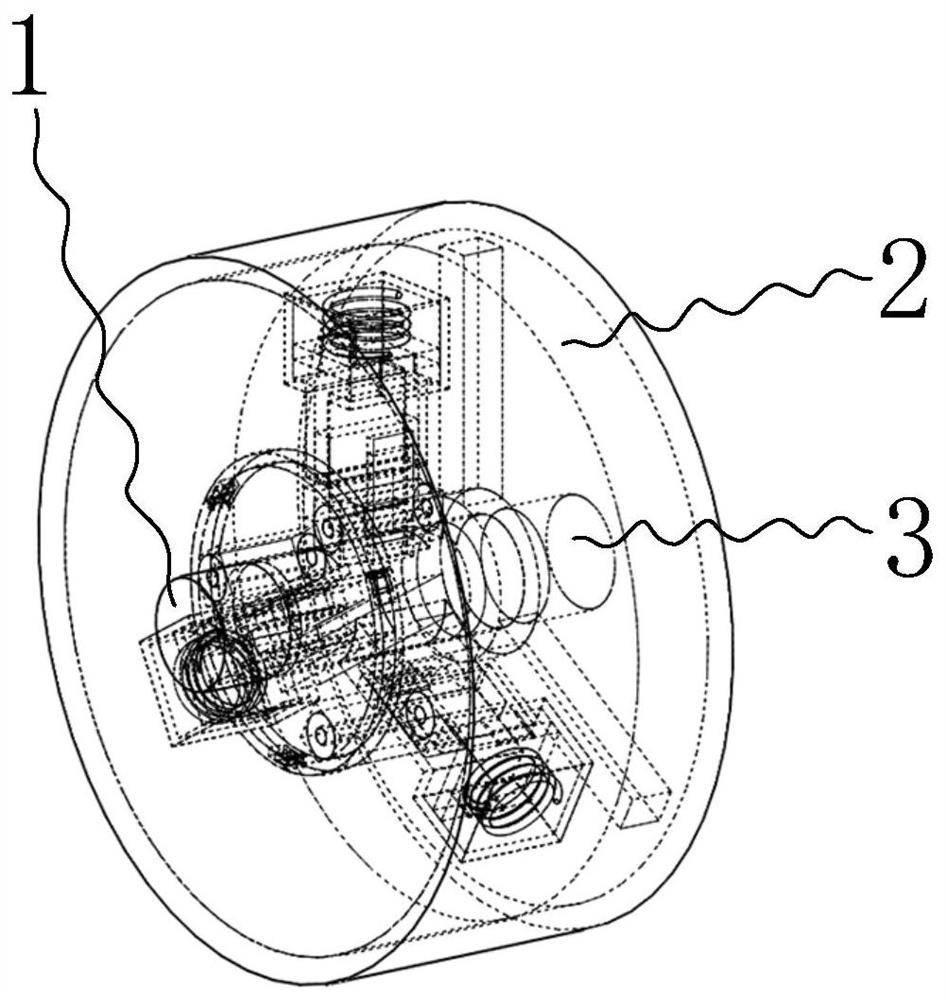

a transmission mechanism

A technology of transmission mechanism and sliding plate, which is applied to the transmission device, gear transmission device, transmission device parts, etc., and can solve the problem of reducing the transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

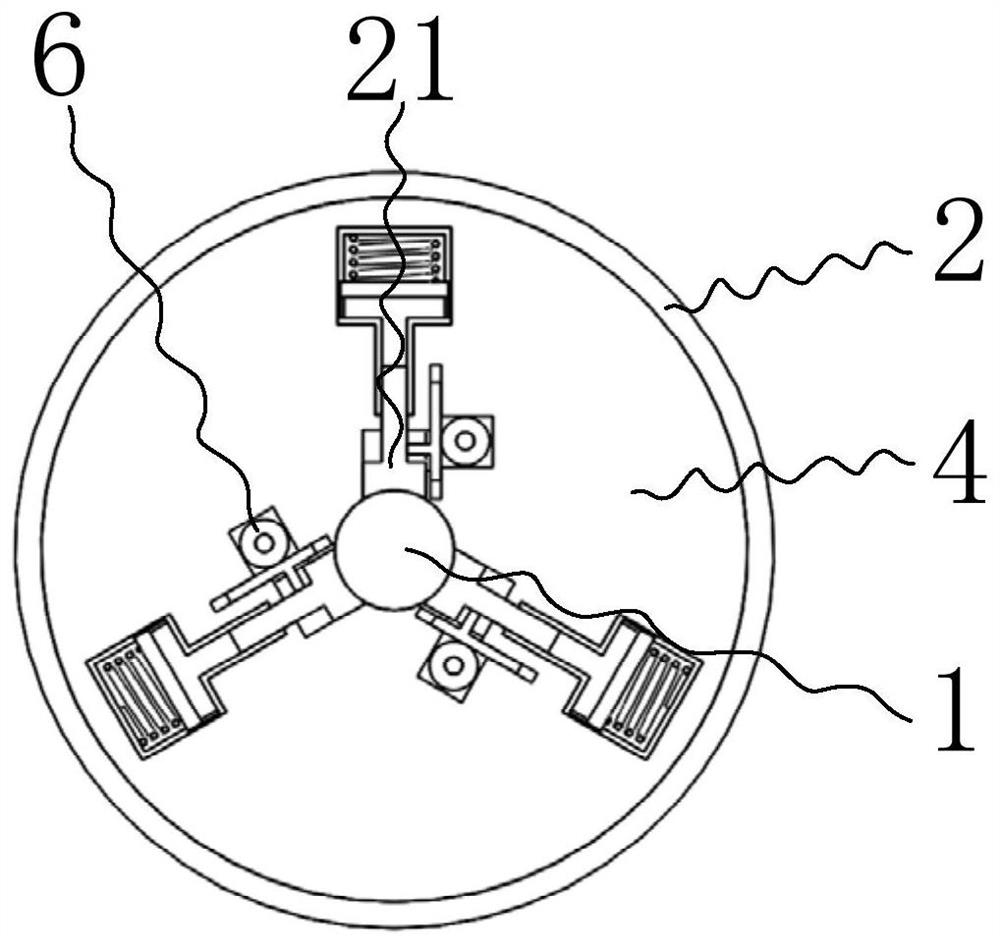

[0057] Specific implementation method: when using the transmission mechanism designed by the present invention, during normal use, the input shaft 3 will drive the installation shell 2 to rotate, and the rotation of the installation shell 2 will drive the drive cylinder 4 on which it is installed to rotate, and the rotation of the drive cylinder 4 will drive the three adjustments. The shell 19 rotates around the output shaft 1, the rotation of the three adjusting shells 19 drives the three friction blocks 21 to rotate around the output shaft 1, and the rotation of the three friction blocks 21 around the output shaft 1 will drive the output under the action of the friction pressure. The shaft 1 rotates, that is, the input shaft 3 drives the output shaft 1 to rotate; when the drive mechanism is used for a long time, the three friction blocks 21 will be worn. In this state, because the first spring 10 is in the initial state Compression pre-tightening state, so at this time under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com