High-performance energy-saving commercial steamer and control method thereof

A high-performance, commercial technology, applied in the field of commercial steamers, can solve the problems of waste of energy consumption, potential safety hazards, and low energy efficiency utilization in steamers, and achieve the effects of preventing energy waste, shortening heating time, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

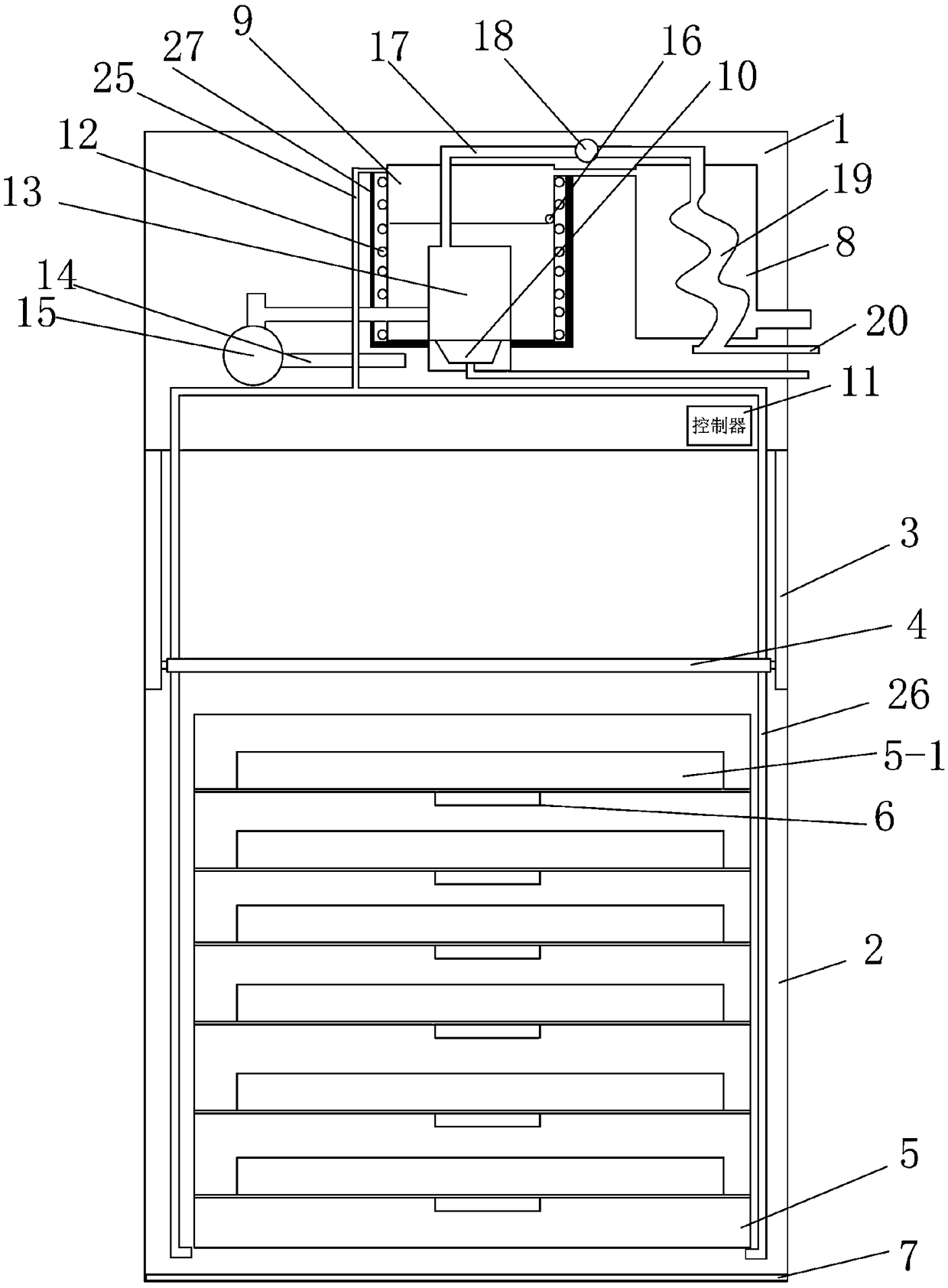

[0020] like figure 1 As shown, a high-performance energy-saving commercial steamer provided in this embodiment includes a steam control layer 1 and a steaming chamber 2 isolated up and down, and a slideway 3 is provided on both sides of the upper end of the steaming chamber 2, and between the slideways 3 There is a thermal insulation layer 4 that can go up and down the slideway 3 to adjust the height of the steaming chamber 2. In the steaming chamber 2, there is a pull-out steaming rack 5 that can add a steaming compartment 5-1. In the steaming rack 5 Each steaming grid 5-1 is provided with a first gravity sensor 6, a second gravity sensor 7 is provided at the bottom of the steaming chamber 2, and a water tank 8 with an input pipe and a steam generation chamber are provided in the steam control layer 1. 9. The gas burner 10 and the controller 11, the output port of the water tank 8 is connected to the steam generating chamber 9, and the outer layer of the steam generating cham...

Embodiment 2

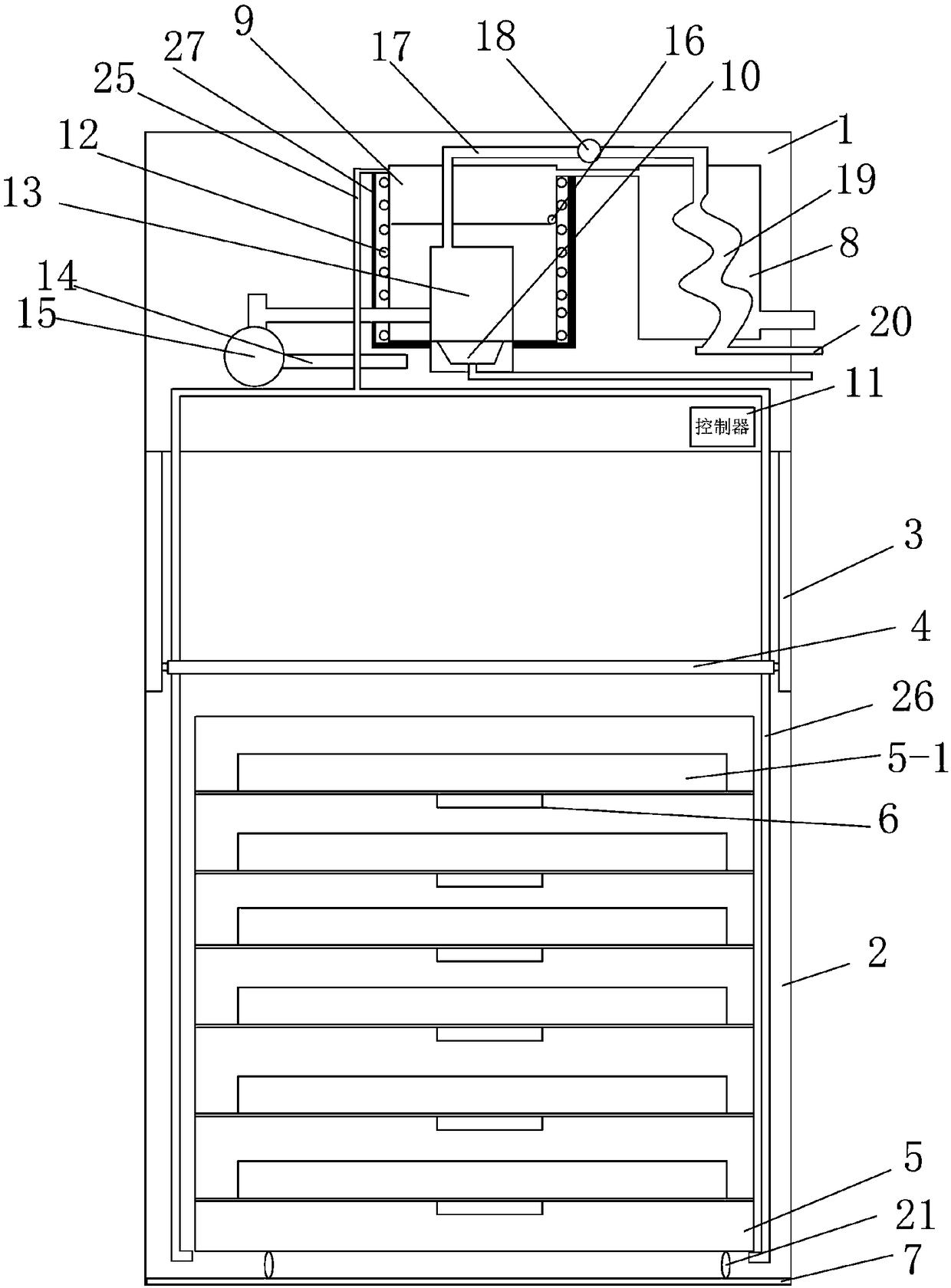

[0024] like figure 2 As shown, the general structure of a high-performance energy-saving commercial steamer provided by this embodiment is the same as that of Embodiment 1, the difference is that, in order to facilitate movement, a pulley 21 is provided at the bottom of the steamer rack 5 to facilitate moving the steamer rack 5 .

Embodiment 3

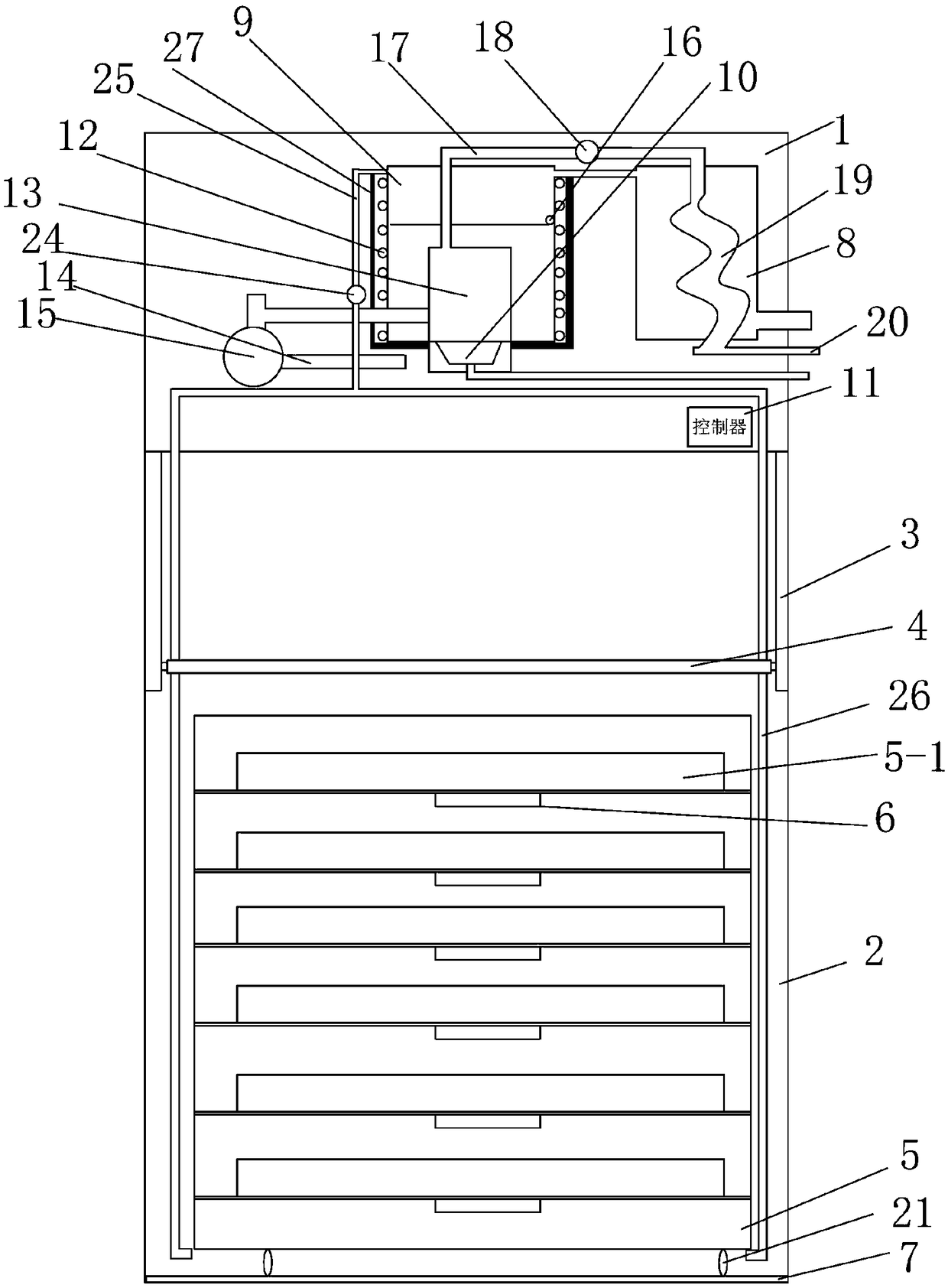

[0026] like image 3 As shown, the general structure of a high-performance energy-saving commercial steamer provided by this embodiment is the same as that of Embodiment 2, the difference is that, in order to improve work efficiency, the steam pipe 25 and the steam inlet pipes on both sides of the steam chamber 2 26 are connected by the second ventilation device 24.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap