Stirring device for organic-inorganic compound fertilizer

A technology of compound fertilizer and mixing device, which is applied to mixers with rotary mixing devices, mixer accessories, mixers, etc., can solve the problems of single setting mode, poor mixing effect, low mixing efficiency, etc., and achieves easy replacement and operation. The effect of improving the stirring effect and improving the stirring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

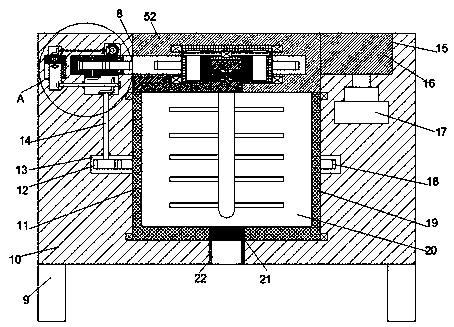

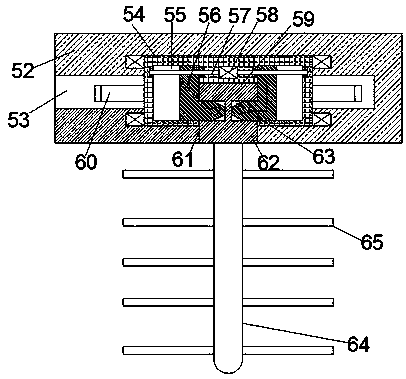

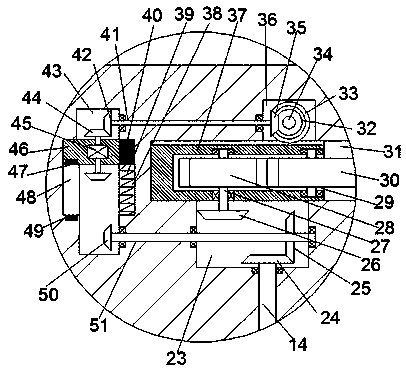

[0022] Such as Figure 1-3As shown, a stirring device of an organic-inorganic compound fertilizer of the present invention includes an installation box 10 fixedly arranged on a bracket 9 and a stirring structure arranged in the installation box 10, and the installation box 10 is provided with a first An adapter chamber 11, the inner top wall of the first adapter chamber 11 is provided with a first connection groove 8 communicating with the outside, and the left and right of the installation box 10 are extended to be provided with through the first adapter chamber 11 The second transition cavity 13, the first transition cavity 11 is rotatably installed with a stirring box 19 through a bearing, and the outer surface of the stirring box 19 is fixedly provided with a groove extending into the second transition cavity 13 The outer ring gear 18 of the first connecting groove 8 is provided with a first sliding connection groove 31 extending leftward in the left end wall of the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com