LED support three dimensional ink coating die

A three-dimensional, mold-based technology, which is applied to the device and coating of the surface coating liquid, can solve the problem of not being able to brush black lamp beads, and achieve the effect of accurate parking position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

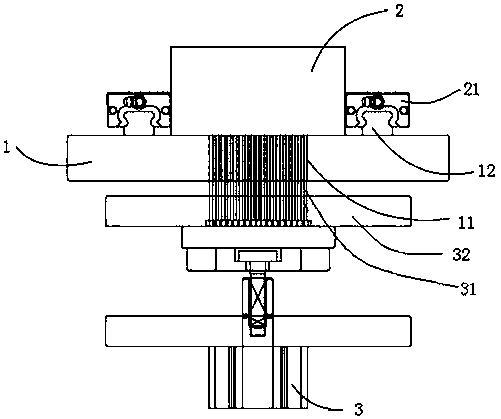

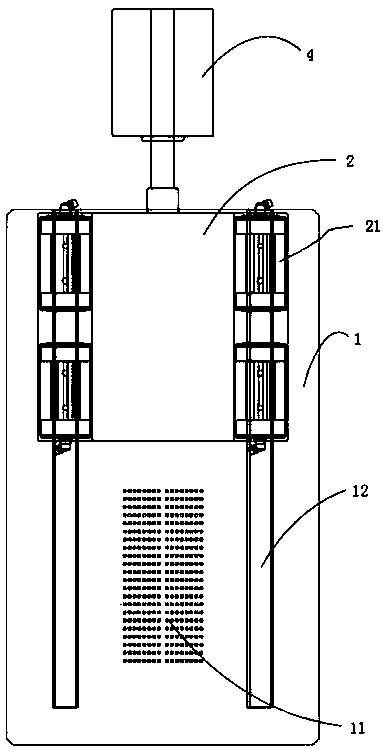

[0033] like figure 2 and Figure 4 , a LED bracket three-dimensional ink brush mold, which includes

[0034] A frame, the frame is provided with a bottom plate 1, and one side of the bottom plate 1 is provided with several through holes 11 penetrating the bottom plate from top to bottom;

[0035] The ink cartridge 2 is arranged above the other side of the bottom plate 1, the ink cartridge 2 is a box body with an open bottom, and the ink cartridge is arranged on the bottom plate 1 so as to be movable back and forth;

[0036] The core 31 is movably arranged in the through hole 11, and the core 31 fits with the through hole 11 with a small gap;

[0037] The first driving device 3 is connected to the lower end of the core 31 through a connecting plate, and the first driving device 3 is arranged on the frame and located below the bottom plate 1 .

[0038] The first driving device 3 is a pneumatic telescopic device, and the pneumatic telescopic device includes a telescopic rod a...

Embodiment 2

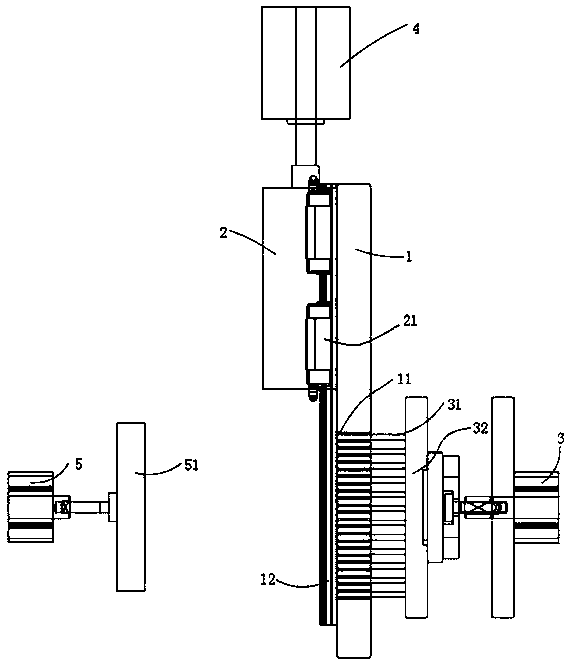

[0046] like image 3 , a LED bracket three-dimensional ink brush mold, which includes

[0047] A frame, the frame is provided with a bottom plate 1, and one side of the bottom plate 1 is provided with several through holes 11 penetrating the bottom plate from top to bottom;

[0048] The ink cartridge 2 is arranged above the other side of the bottom plate 1, the ink cartridge 2 is a box body with an open bottom, and the ink cartridge is arranged on the bottom plate 1 so as to be movable back and forth;

[0049] The core 31 is movably arranged in the through hole 11, and the core 31 fits with the through hole 11 with a small gap;

[0050] The first driving device 3 is connected to the lower end of the core 31 through a connecting plate, and the first driving device 3 is arranged on the frame and located below the bottom plate 1 .

[0051] The first driving device 3 is a pneumatic telescopic device, and the pneumatic telescopic device includes a telescopic rod and a cylinder, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com