Flat knitting machine yarn nozzle control self-running yarn nozzle servo system and method thereof

A technology of flat knitting knitting machine and servo system, which is applied in knitting, weft knitting, textile and papermaking, etc., can solve the problem that the yarn feeder cannot obtain the current position information of the machine head, reduces the inertia of the machine head, has no communication connection, etc., and achieves noise. Small, high communication speed, no impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

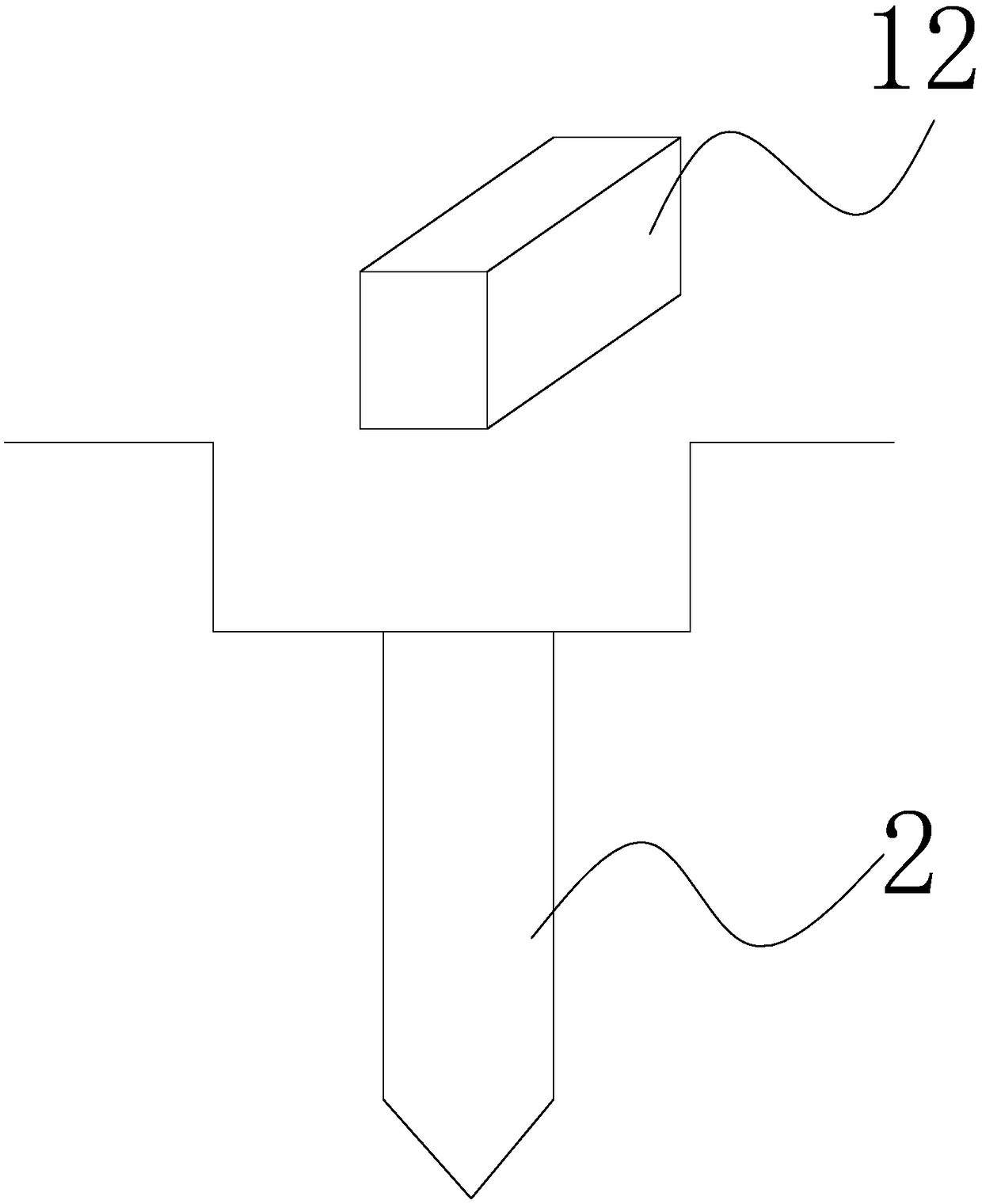

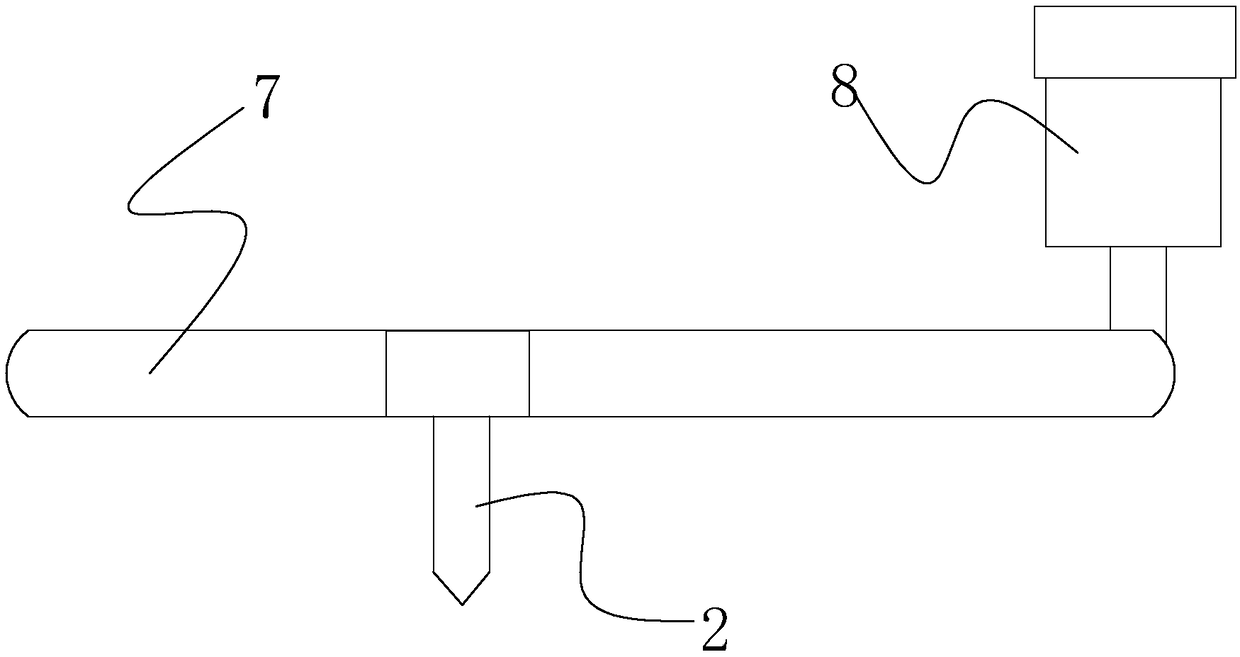

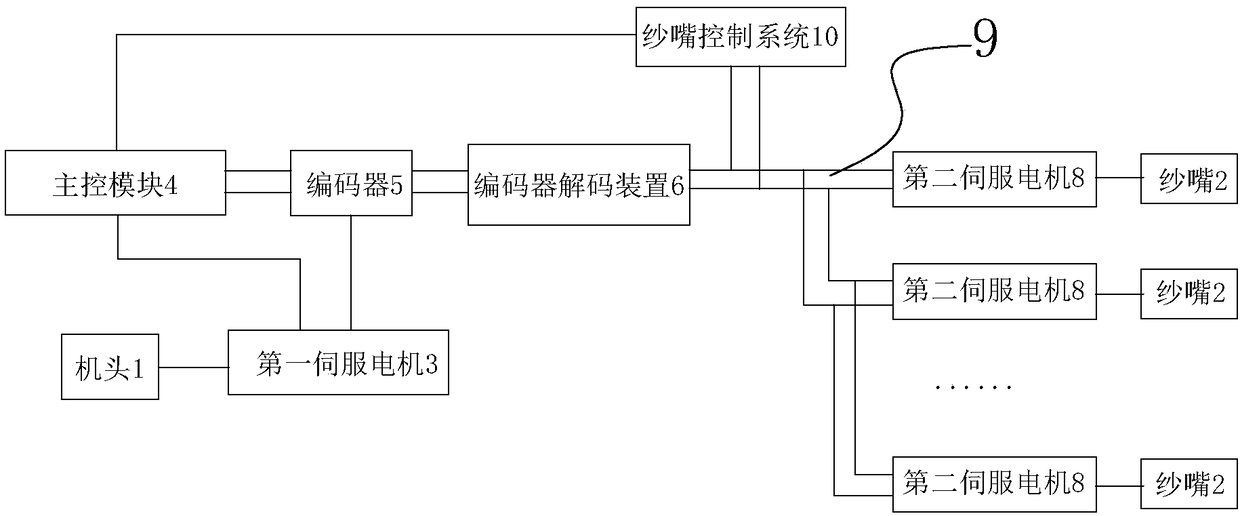

[0034] Such as figure 2 with image 3 As shown, this embodiment discloses a yarn feeder control self-running yarn feeder servo system for a flat knitting machine, including a machine head 1 and several yarn feeders 2, the machine head 1 is connected to a first servo motor 3, and the first servo motor 3 Connected to the main control module 4 and the encoder 5 respectively, the encoder 5 is respectively connected to the main control module 4 and the encoder decoding device 6 through the data transmission line 9, and each yarn feeder 2 is connected to the second servo motor 8 through the timing belt 7 , the encoder decoding device 6 is connected to the yarn feeder control system 10 and each second servo motor 8 through the data transmission line 9, and the yarn feeder control system 10 is connected to each second servo motor 8 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com