Track shoe assembly assembling device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

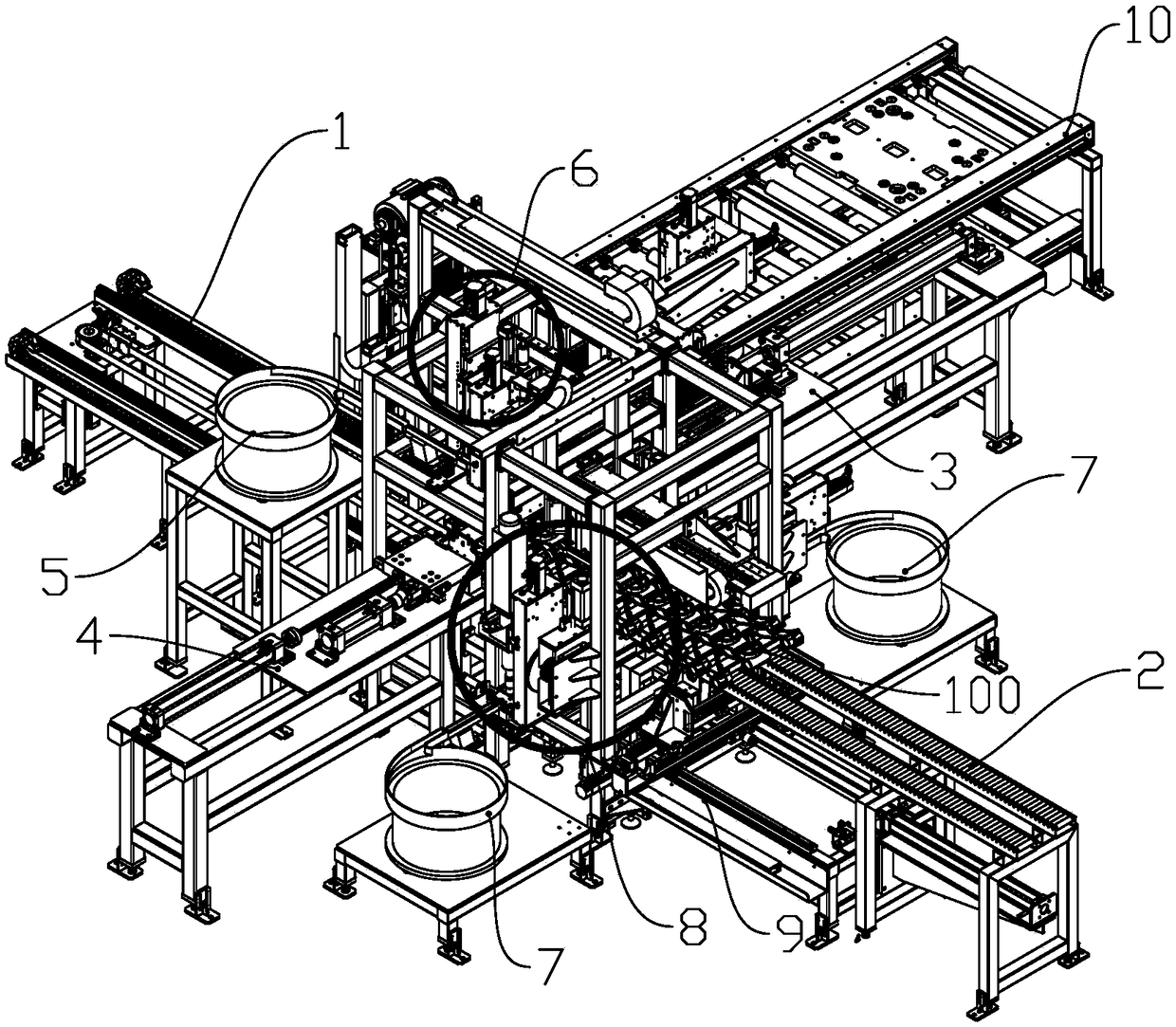

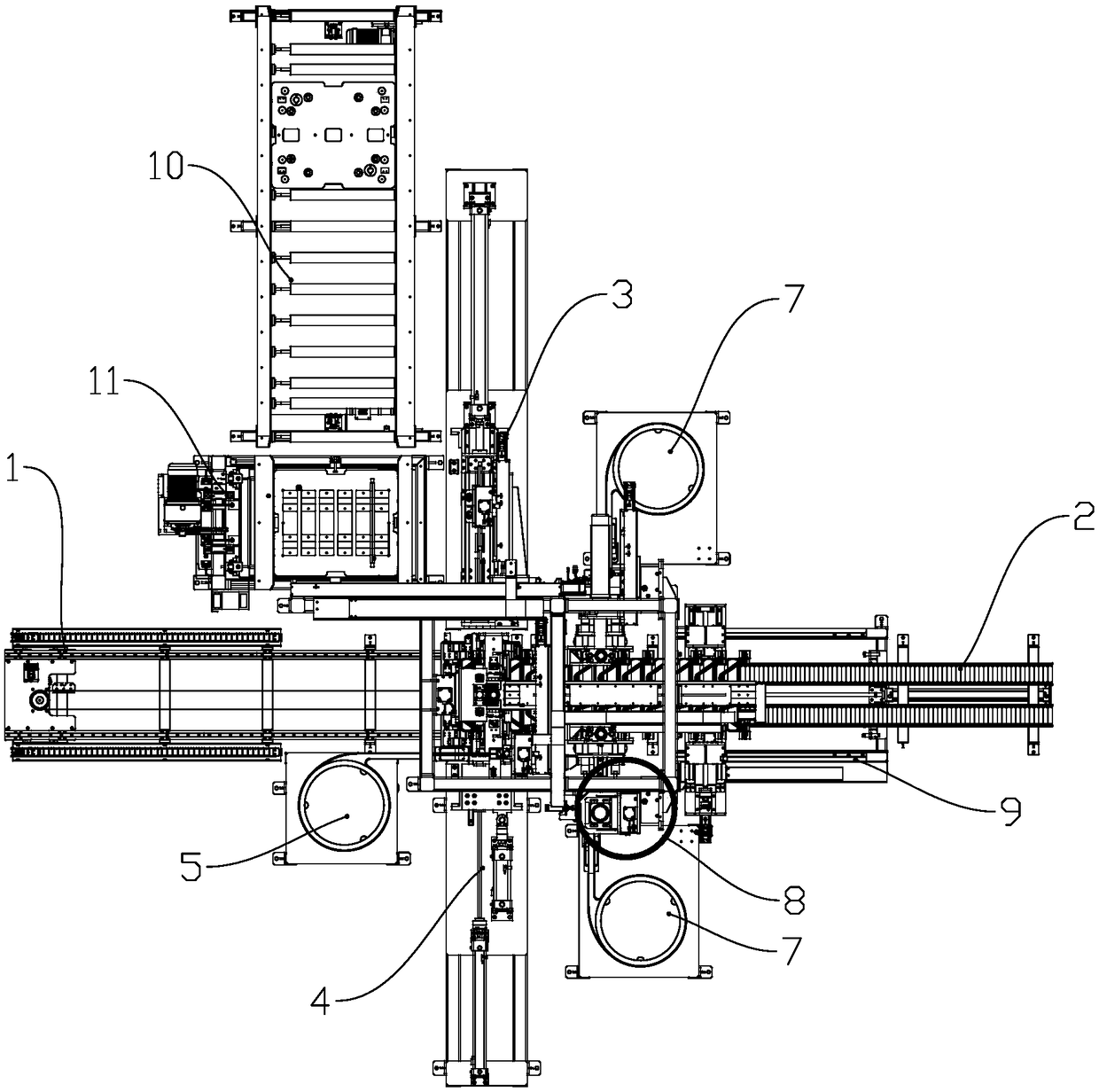

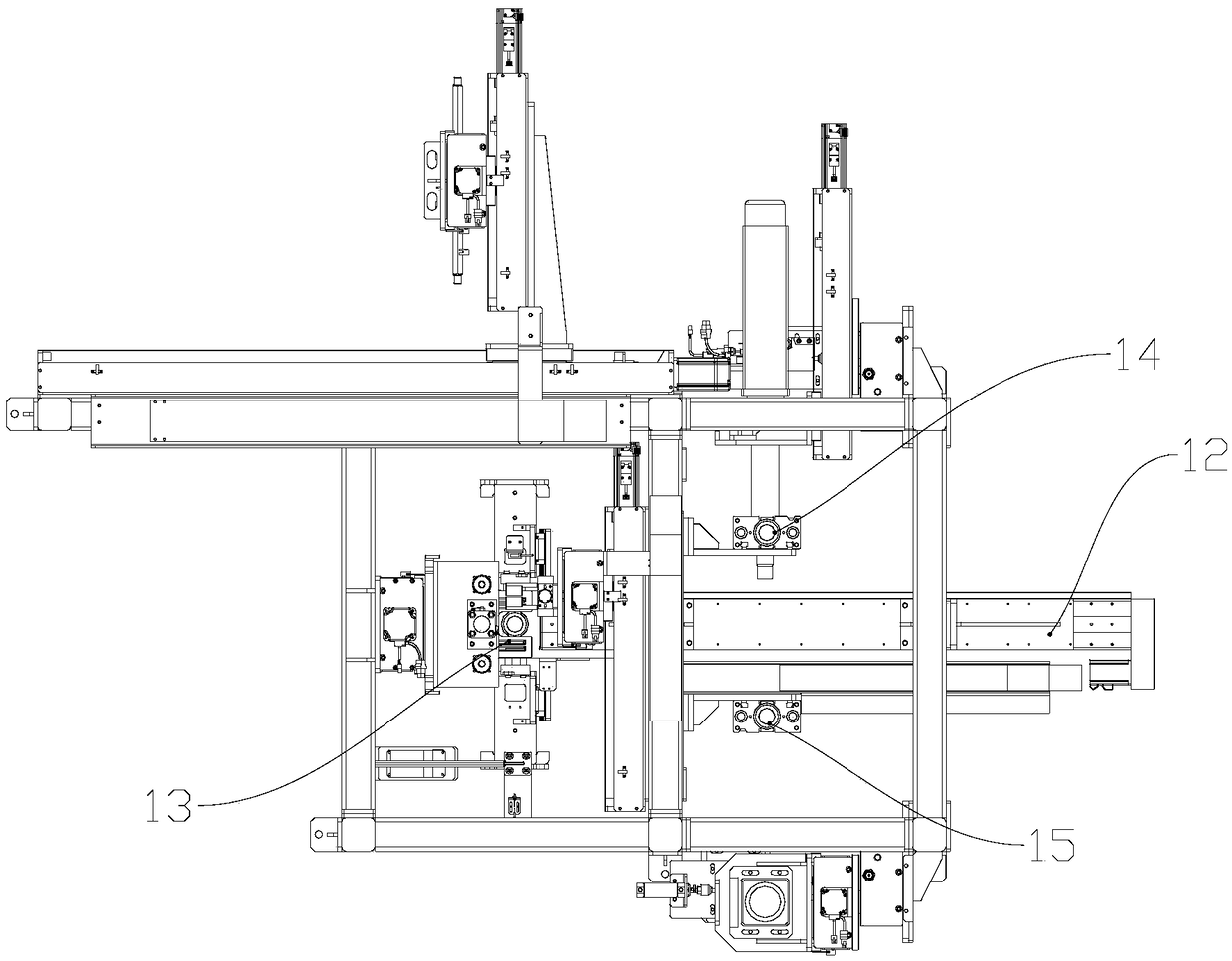

[0105] Such as figure 1 and figure 2 As shown, the track shoe conveyor line in this embodiment includes a conveyor belt 1 , a driving assembly for controlling the reciprocating movement of the conveyor belt 1 , and an output line 2 connected with the conveyor belt 1 . The output line 2 in this embodiment is a non-powered output line, which is formed by arranging a plurality of conveying rollers. In this embodiment, there is an interval in the track shoe conveying line to facilitate the installation of the above-mentioned first positioning mechanism and other mechanisms.

[0106] In this embodiment, the transmission direction of the track veneer is the front-to-back direction, and the above-mentioned pin hole positioning mechanism 4 and the latch mechanism 3 are installed at the junction of the conveyor belt 1 and the output line 2, and a gasket is provided above the conveyor belt at the track pin installation mechanism. The mounting mechanism 6 is provided with a nut mounti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com