Synchronous belt wheel

A synchronous pulley and synchronous belt technology, applied in the direction of conveyor objects, conveyors, transportation and packaging, etc., can solve problems such as mechanical failure, synchronous pulley damage, jamming, etc., to reduce the failure rate, prevent deviation or Shedding, the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with examples. The examples are only used to explain the present invention and do not constitute a limitation on the protection scope of the present invention.

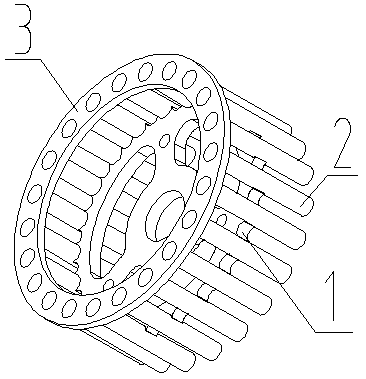

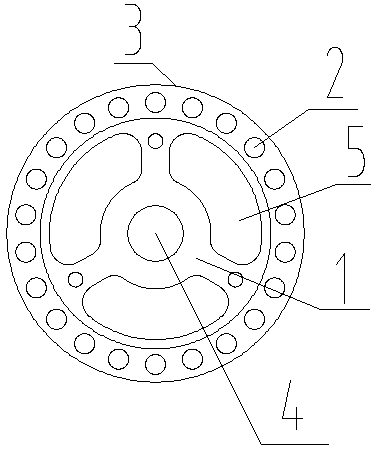

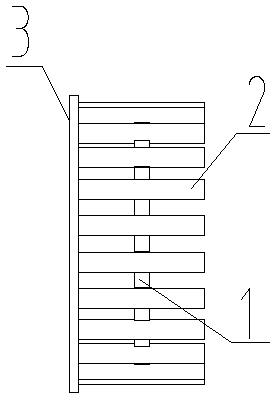

[0013] Such as Figure 1-3 As shown, this embodiment provides a synchronous belt wheel, which includes a circular wheel axle support plate 1 with mounting grooves evenly distributed around the wheel axle support plate 1, and the axle 2 is welded and fixed in the mounting groove, and all the axles 2 are Annularly arranged around the axle support plate 1, the middle part of the axle 2 is welded in the installation groove; the left ends of all axles 2 are welded together and fixed with an annular timing belt limit block 3, and the timing belt limit block 3 has an annular arrangement Positioning hole, the left end of the annular arrangement of axles 2 is inserted into the annula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com