Voltage transformation site overhaul device

A technology for maintenance devices and places, applied in the direction of lifting devices, etc., can solve problems such as complicated operation, single function, danger, etc., and achieve the effect of avoiding danger and complicated operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Hereinafter, the present invention will be further described through embodiments in conjunction with the drawings.

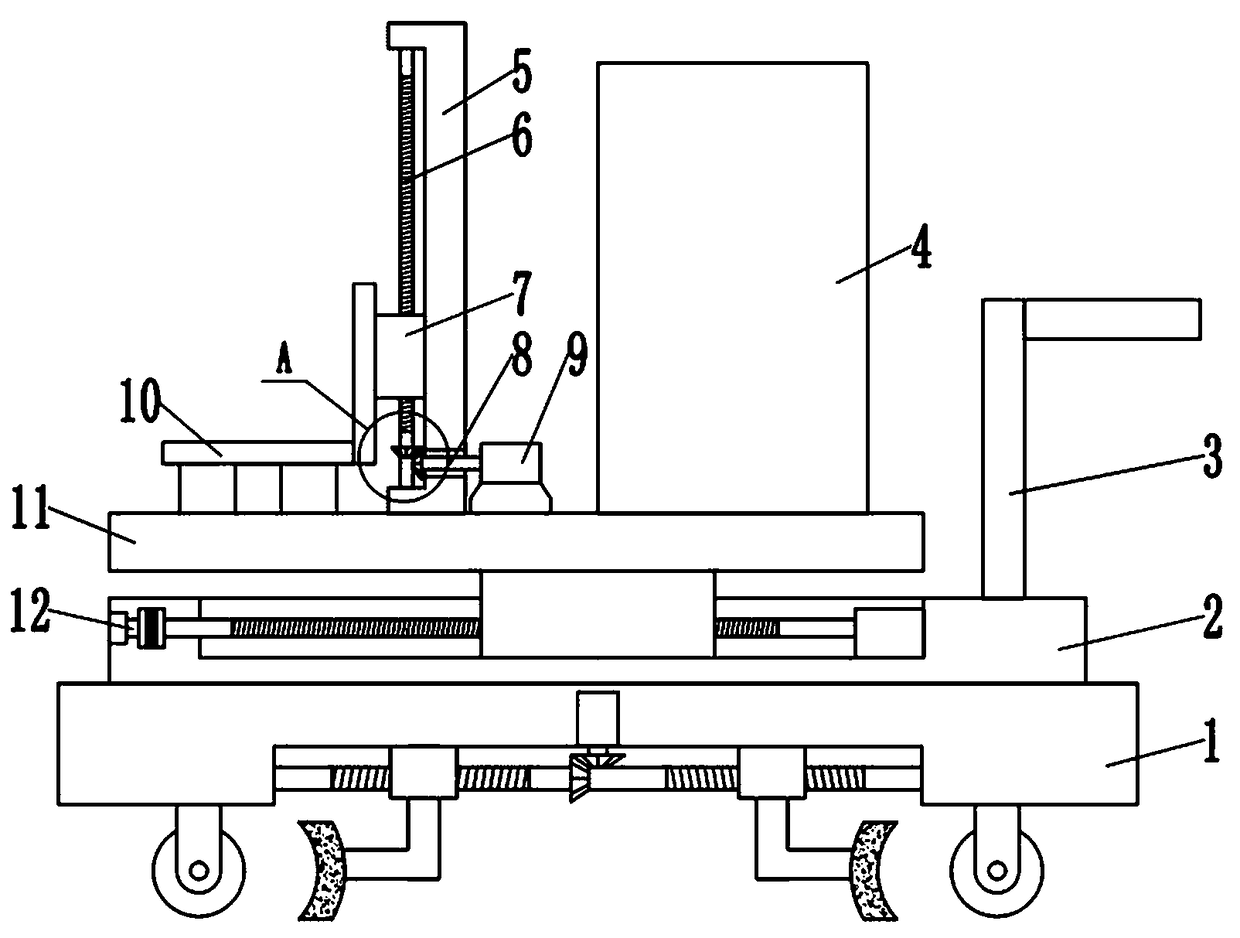

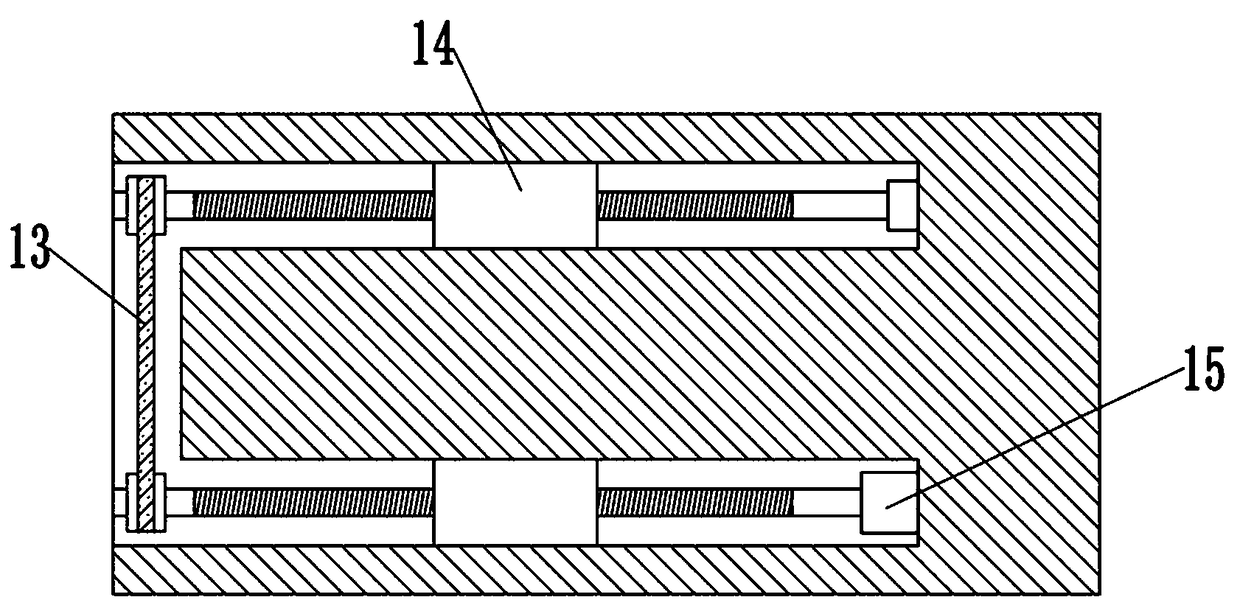

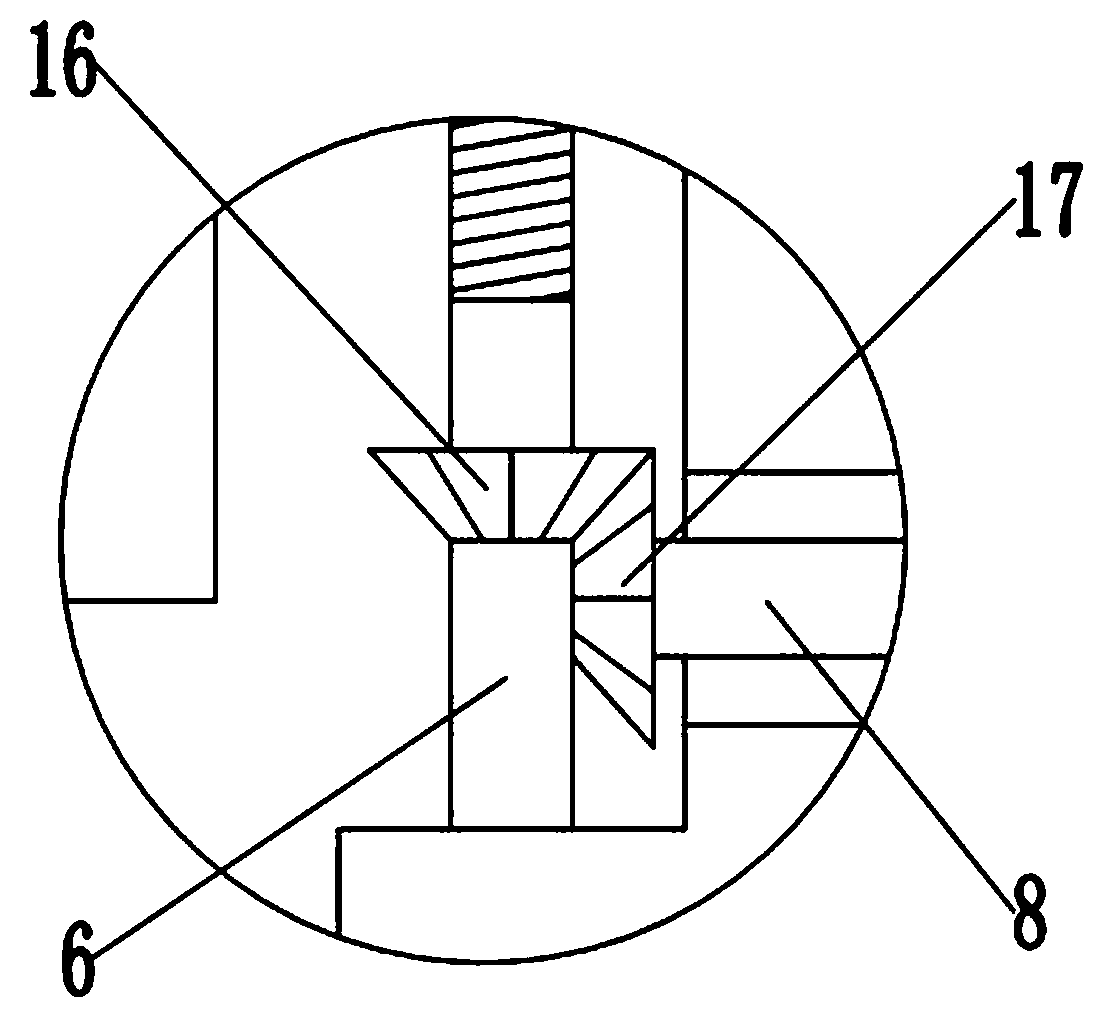

[0023] Such as Figure 1 to Figure 4 As shown, the transformer site maintenance device of the present invention includes a base 1, a fixed seat 2 and a sliding seat 11. The bottom of the base 1 is equipped with casters 24 to drive the entire maintenance device to move, and a translation mechanism is provided in the base 1 to drive The brake pad 23 moves back and forth to fit or separate with the casters 24, and the entire device can be reliably fixed during maintenance, so as to ensure the safe operation of maintenance personnel.

[0024] The fixed base 2 is installed above the base 1, and a forward and backward moving mechanism is arranged inside it, which can drive the sliding base 11 above it to move back and forth, thereby changing the length of the sliding base 11 extending out of the fixed base 2 to adjust the sliding The distance between the safety sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com