A trough rail and I-rail connecting structure and welding method

A technology of connecting structure and I-shaped rail, applied in the field of rail, can solve the problems of insufficient connection strength, affecting vehicle stability, increasing production cost, etc., and achieving the effects of increasing welding area, improving welding strength, and improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

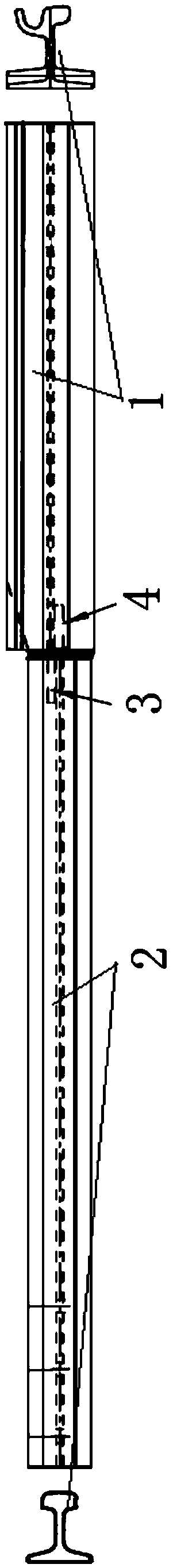

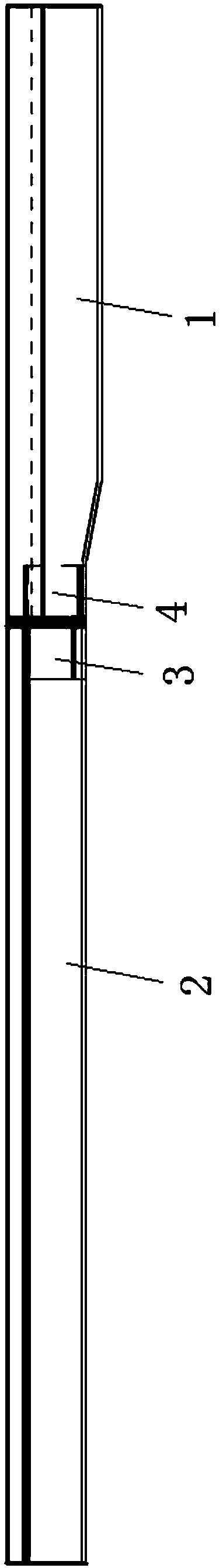

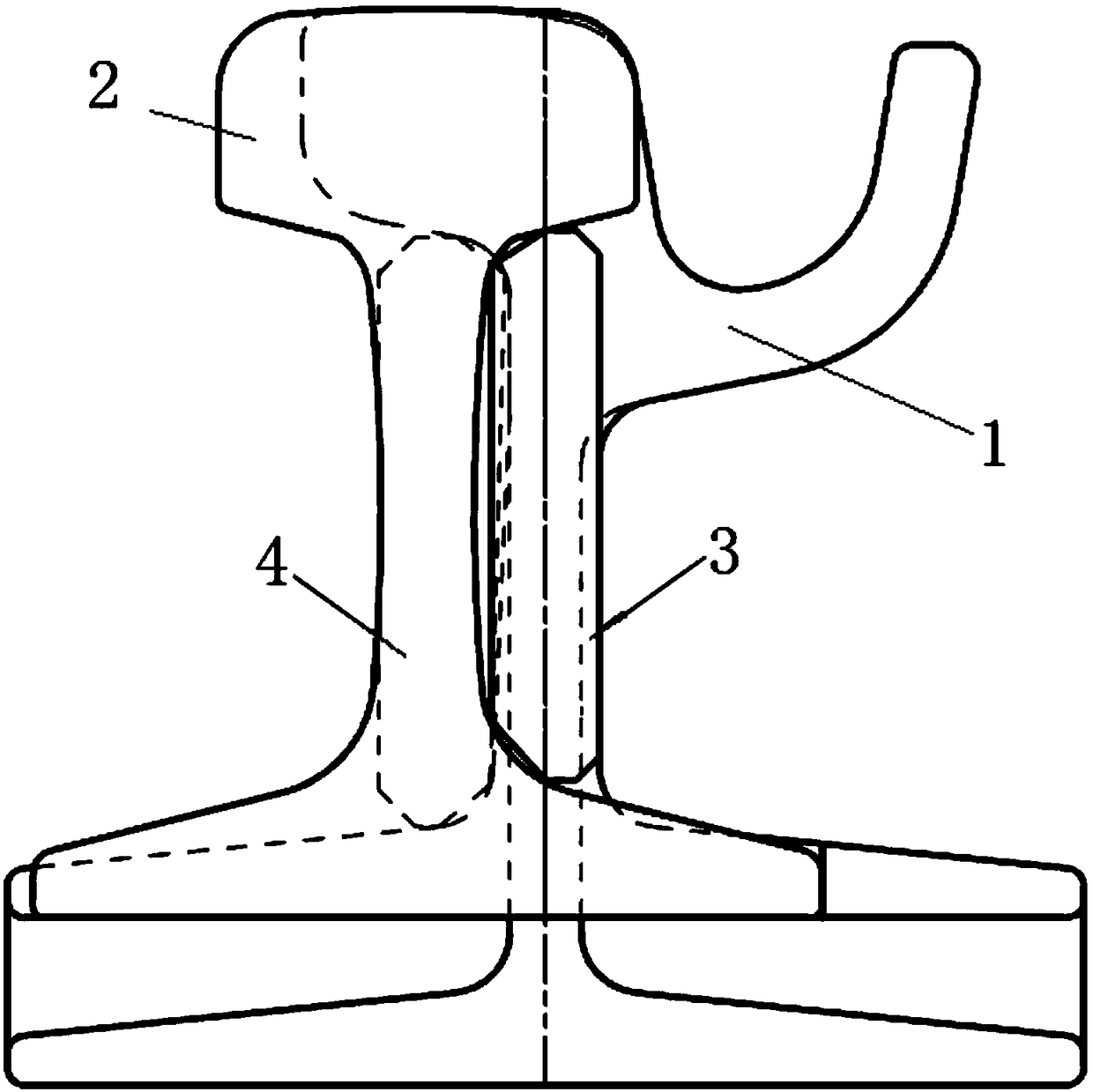

[0032] Such as Figure 1-Figure 4 As shown, the present invention provides a connection structure and welding method between a grooved rail and an I-shaped rail. The connection structure between the grooved rail and the I-shaped rail includes a grooved rail, an I-shaped rail 2 and a special-shaped transition rail 1. Consistent, the special-shaped transition rail 1 includes a grooved track section, a transition section and an I-shaped rail connection section, the shape of the grooved track section is the same as that of the grooved rail, and the I-shaped rail connection section is the same as the I-shaped rail connection section. The rail 2 is connected by welding, and the grooved track section is connected with the grooved rail by welding. Apparently, the connection structure between the grooved track segment and the grooved rail is the same as that between the existing grooved rails by welding, so it will not be described in detail, and this part of the structure is also omi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com