In-situ turn-back method for monorail crane

A technology of monorail cranes and locomotives, which can be used in earth drilling, underground transportation, mining equipment, etc., and can solve problems such as rapid U-turn of monorail cranes and locomotives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

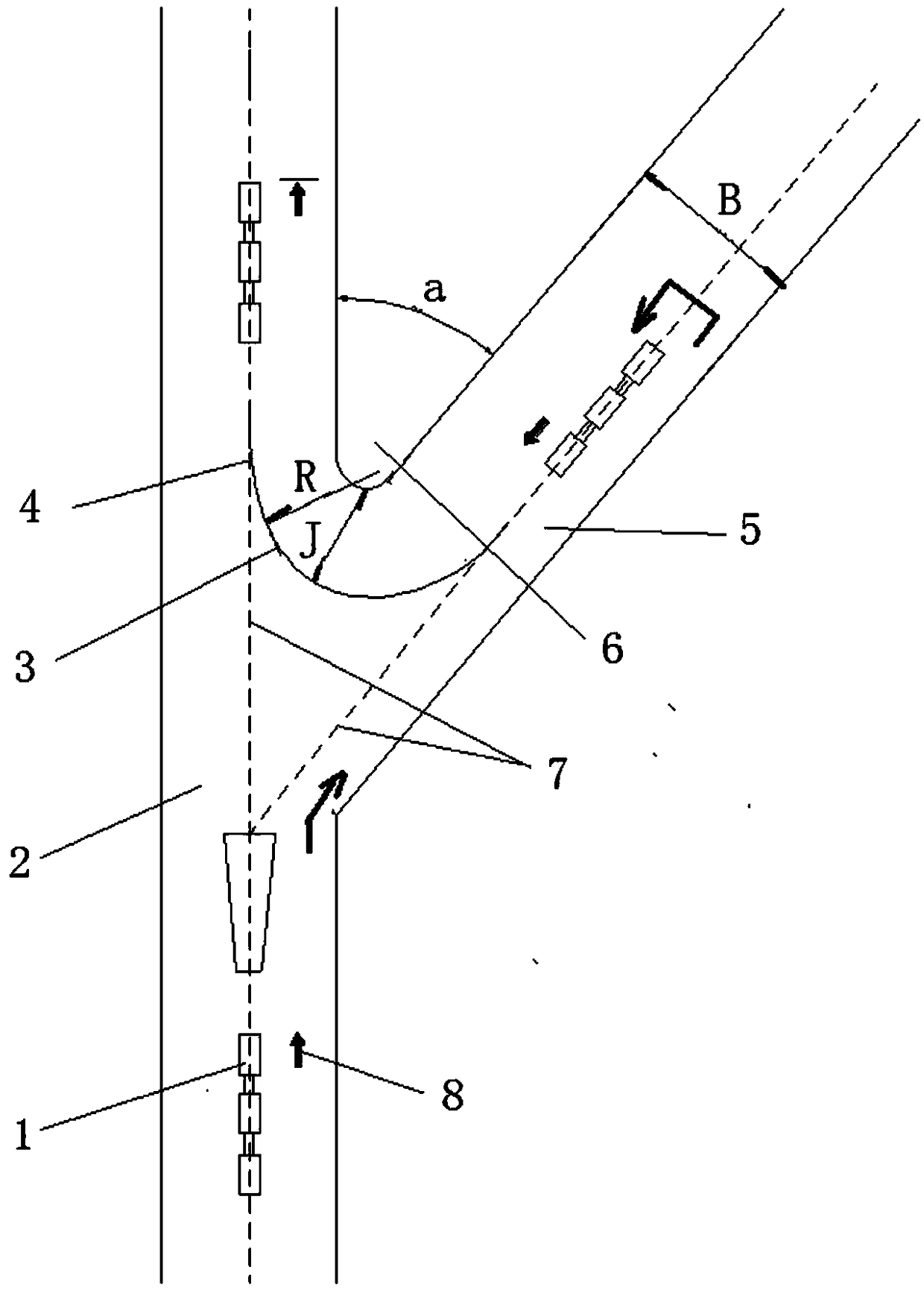

[0019] Such as figure 1 Shown, a kind of monorail locomotive U-turn method on the spot, as follows:

[0020] The first step is to select the branch roadway intersection suitable for U-turn on the spot

[0021] In the main roadway 2 where the monorail locomotive 1 is bifurcated, select the bifurcated roadway 5 with a width B of not less than 3.8m, and the Niubi intersection point 6 at which the angle a at the bifurcation is not less than 40° as the place for turning around on the spot. Through on-site measurement, the construction drawing shall be made according to the size of the turning radius R not less than 4m. When drawing, it is required to calculate the safety clearance J between the monorail locomotive 1 and the intersection point 6 of the bull nose when the monorail locomotive 1 is turning according to the length and width of the monorail locomotive 1; The protruding part conforming to the safety gap J shall be excavated and re-supported;

[0022] The second step is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com