Apparatus for online monitoring heavy load abrasion of tooth type coupling

A technology of gear couplings and monitoring devices, which is applied in the direction of measuring devices, mechanical measuring devices, and mechanical devices, etc., can solve the problems of poor spot inspection accuracy, low efficiency, and inability for novices to confirm, so as to achieve service life and safety Improvement, work efficiency improvement, real-time online accurate spot inspection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

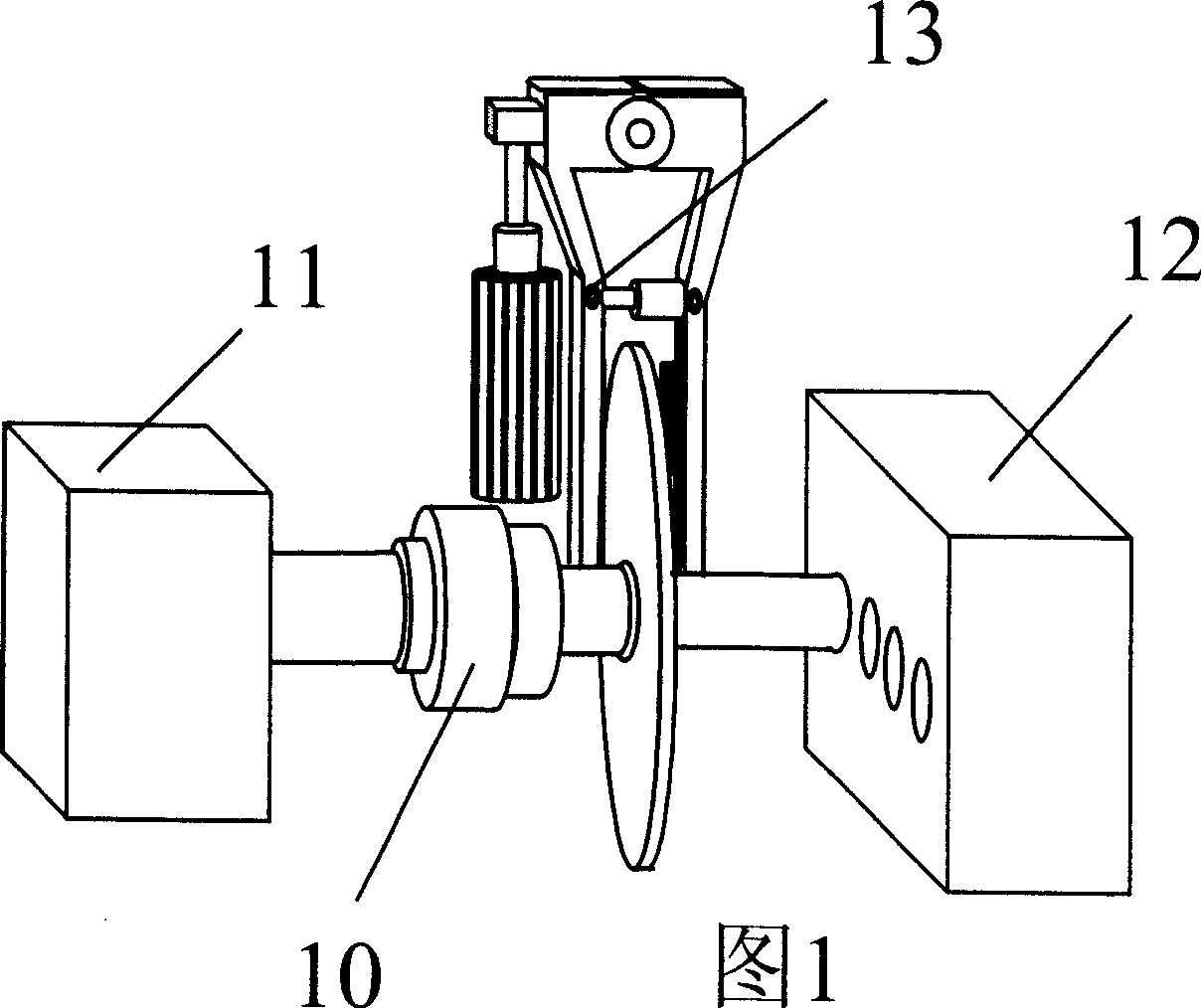

[0022] The heavy-duty on-line monitoring device for gear coupling of the present invention includes a detector, a driver, and an alarm.

[0023] The following describes the detector, driver and alarm respectively as follows:

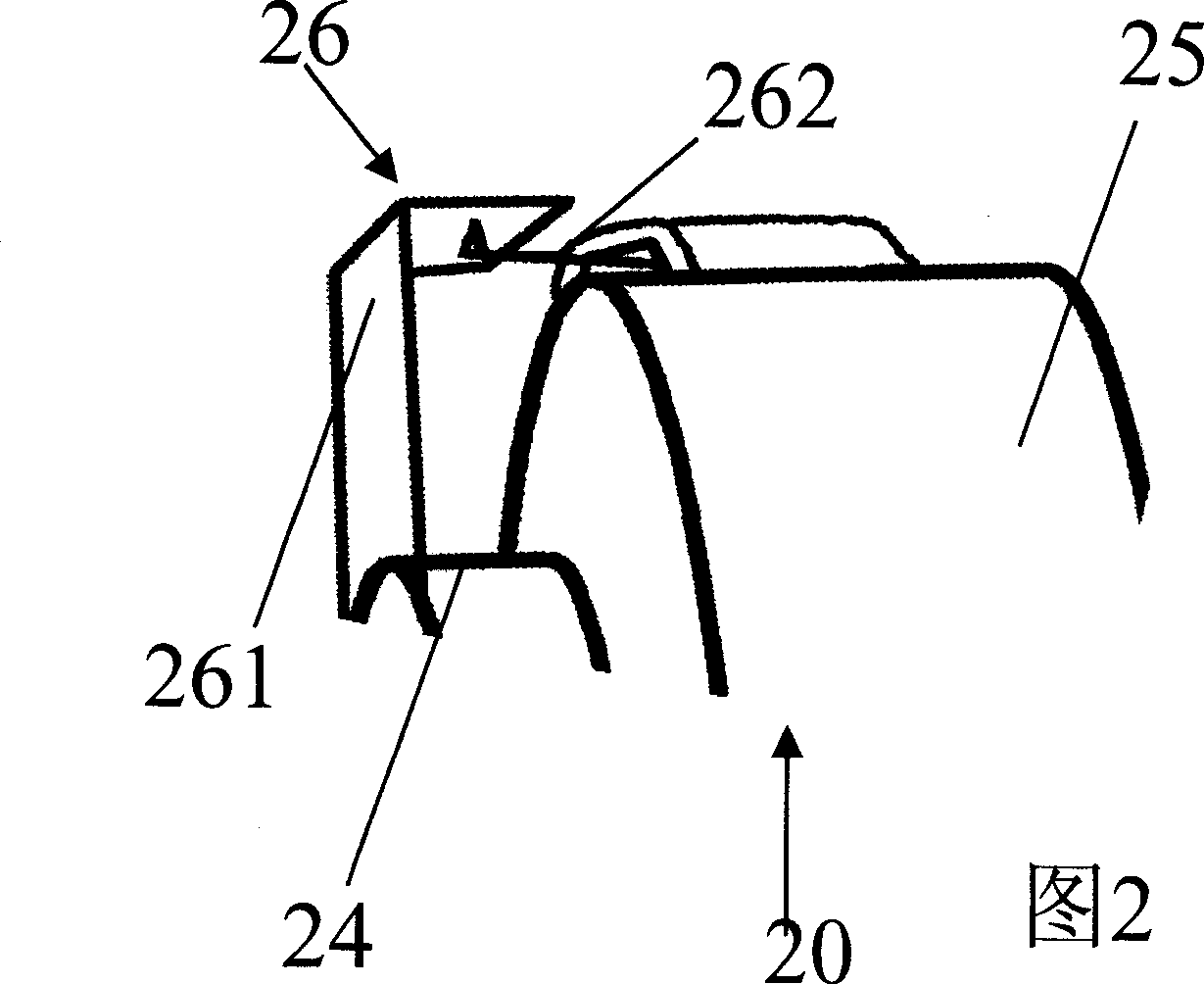

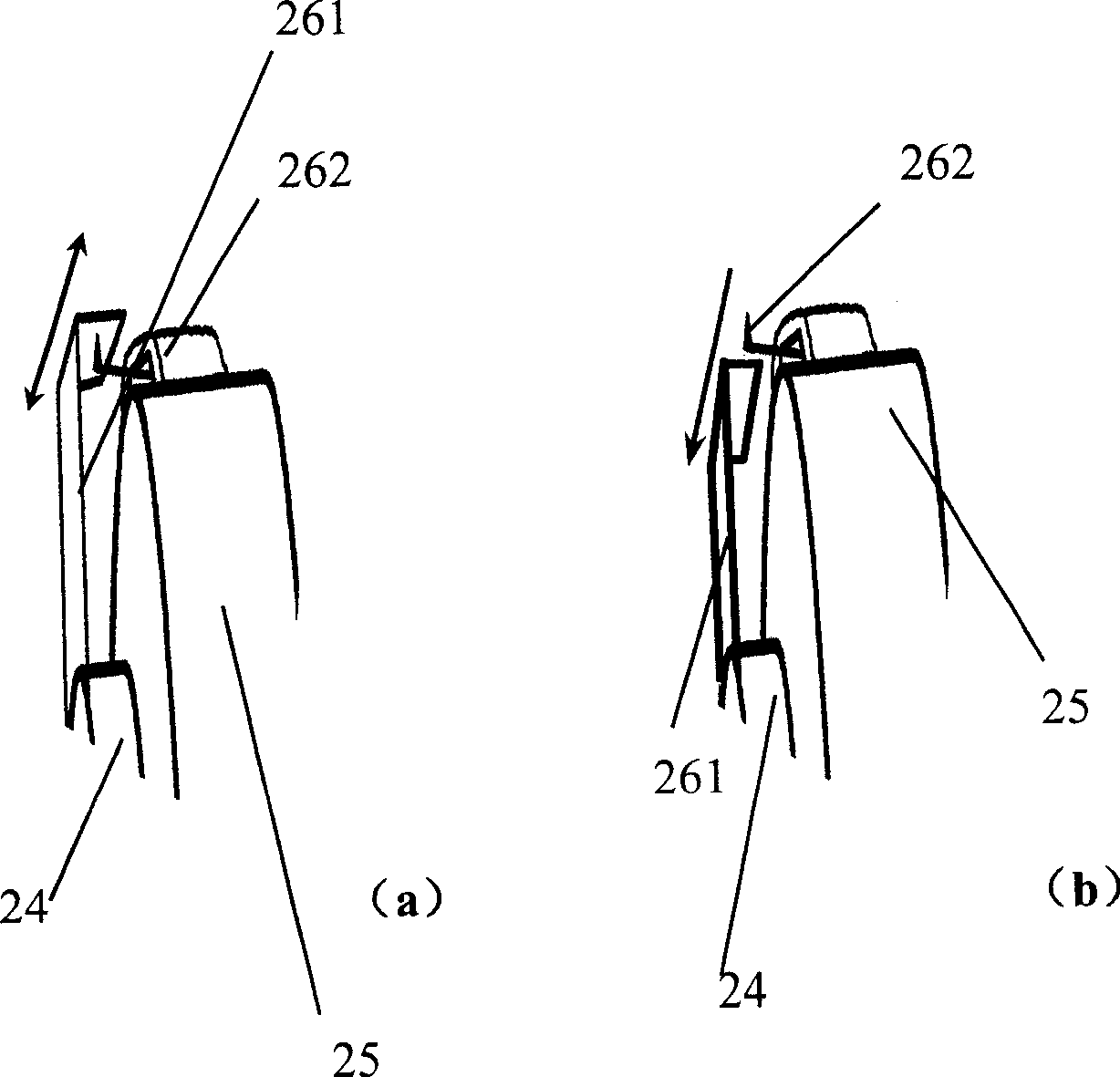

[0024] Please refer to FIG. 2 , the detector 26 includes an elastic contact point 262 , the metal contact piece 261 and the elastic contact point 262 are respectively fixed on the driving shaft 24 of the coupling 20 and the driven shaft 25 of the coupling 20 . That is, the metal contact piece 261 is fixed on the driving shaft 24 of the coupling 20, and the elastic contact point 262 is fixed on the driven shaft 25 of the coupling 20. Of course, the metal contact piece 261 can also be fixed on the passive shaft 20 of the coupling 20. On the shaft 25, the elastic contact point 262 is fixed on the driving shaft 24 of the shaft coupling 20, and no matter how, the metal contact piece 261 and the elastic contact point 262 should be connected to each other when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com