Tooling device for bearing airtightness and dustproof performance detection

A technology of bearing sealing and tooling equipment, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, and detecting the appearance of fluid at the leakage point, etc., which can solve the detection of single performance, inconvenient disassembly and removal operation, and poor versatility, etc. problem, to achieve the effect of convenient detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

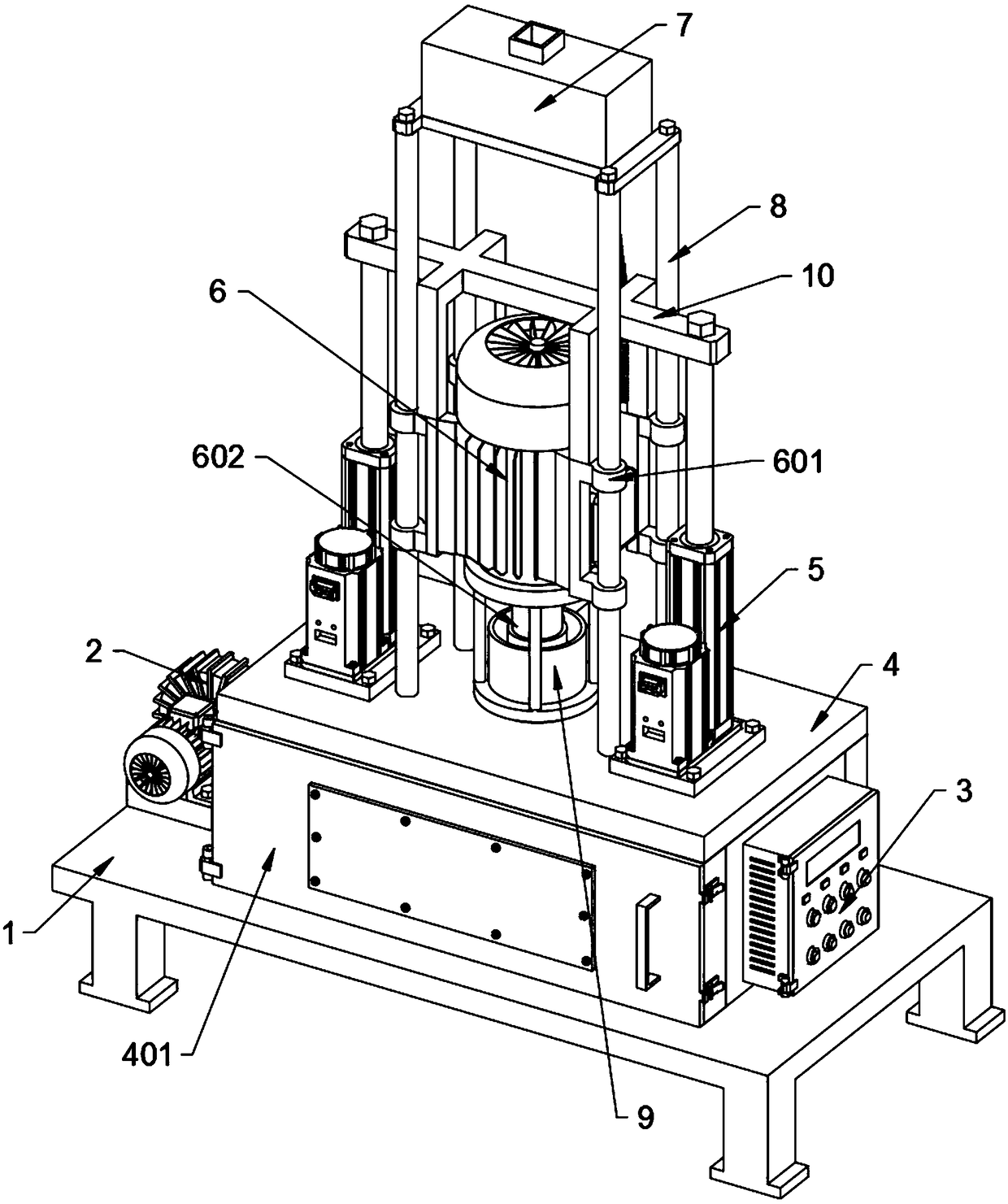

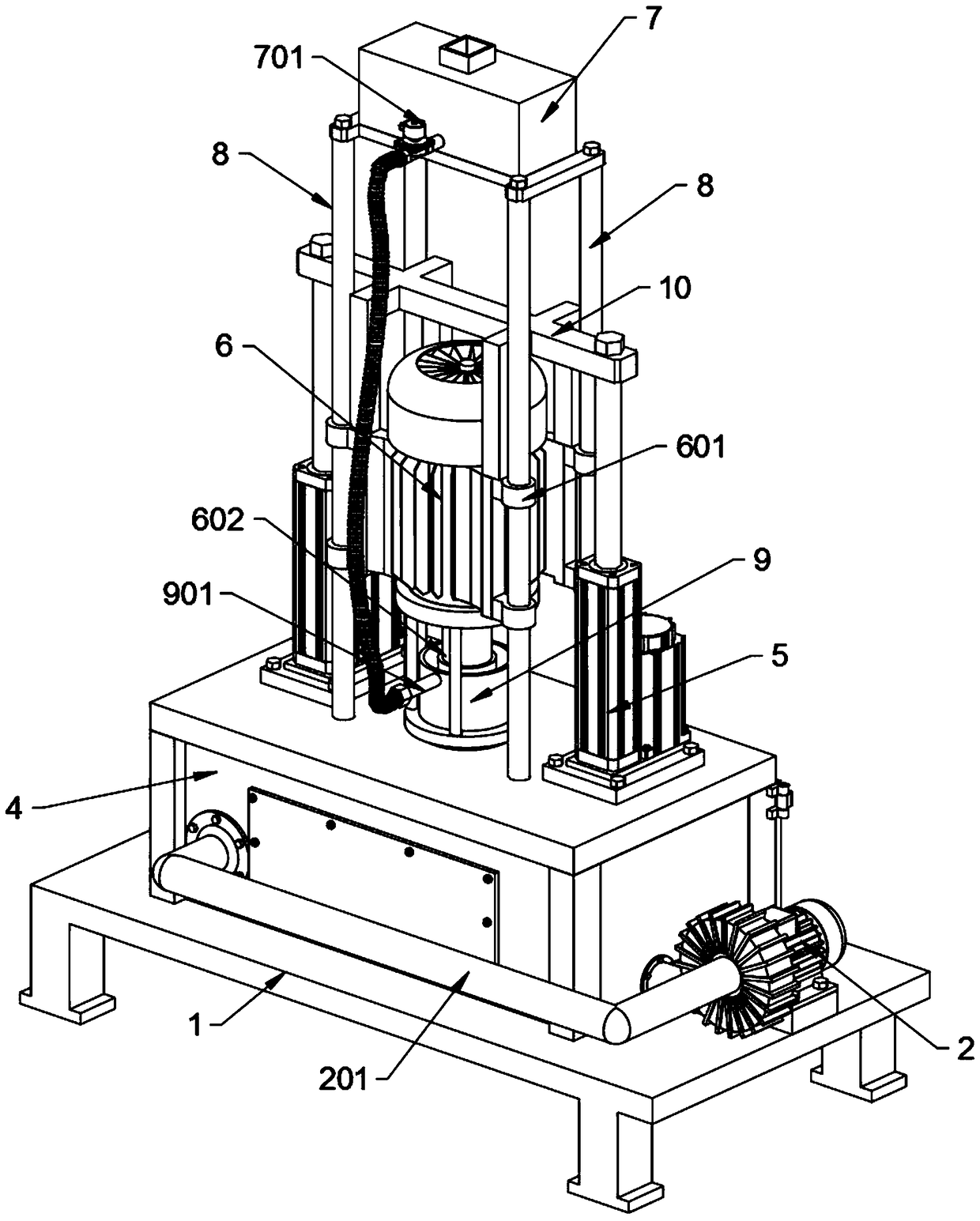

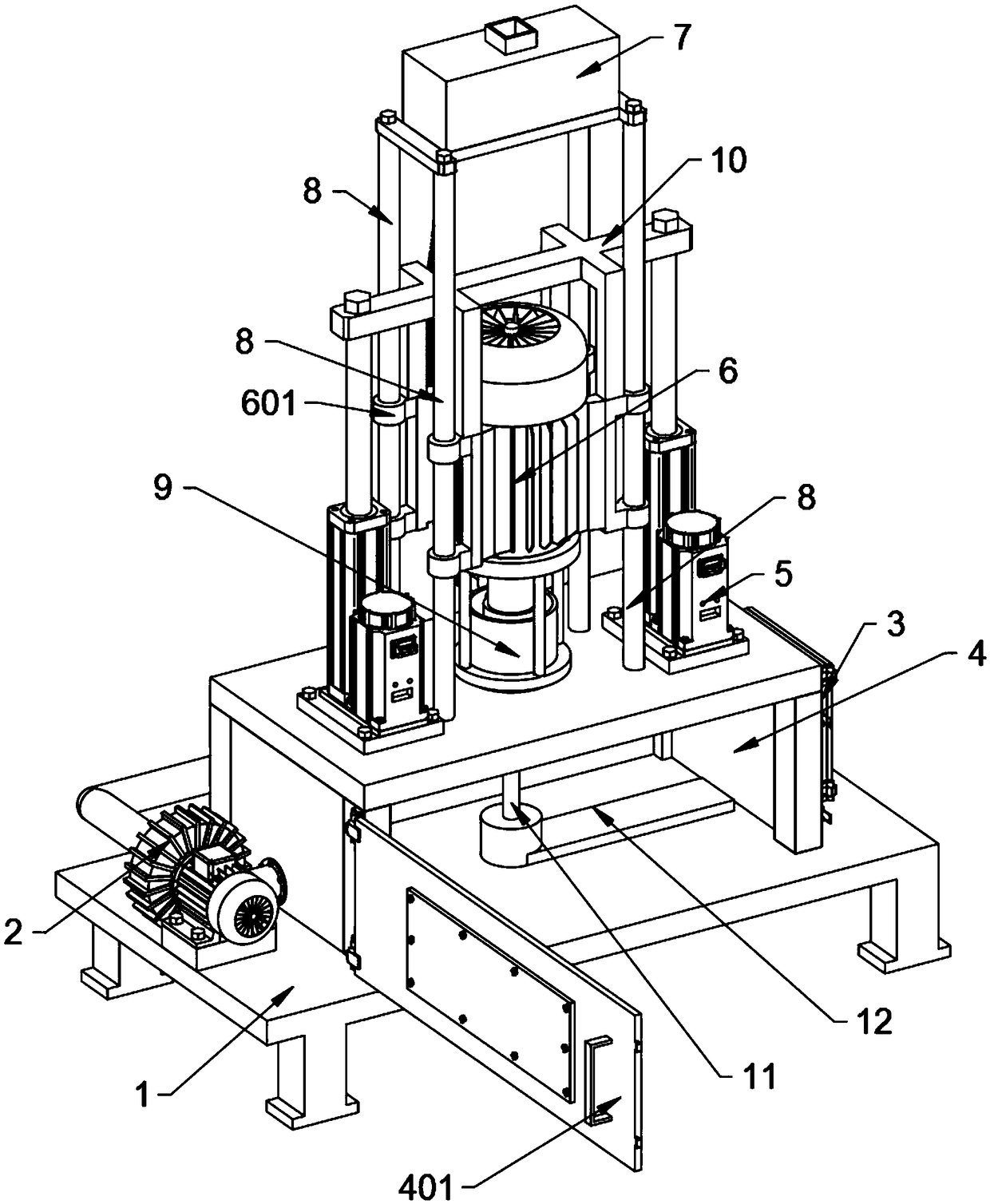

[0040] as attached figure 1 to attach Figure 9 Shown:

[0041] The present invention provides a tooling device for testing bearing sealing performance and dustproof performance, which includes a base 1, a blower 2, an air exhaust duct 201, a control electric box 3, a dust blowing box 4, a box cover 401, a mounting hole 402, a cloth Air blower 403, electric push rod 5, drive motor 6, slip ring 601, motor shaft 602, water tank 7, solenoid valve 701, support positioning shaft 8, water jacket 9, water inlet pipe 901, motor lifting frame 10, positioning rod 11, The hammer plate 12 and the sealed bearing 13, the top of the base 1 is supported and welded with a rectangular structure provided with a dust blowing box 4, and a box cover 401 is placed on the front opening of the dust blowing box 4, which is hinged and tightened. And there is a transparent plastic plate on the rectangular observation port in the middle position of the rear side wall and the box cover 401, and a transpa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com