Centrifugal type thinprep cell slide making machine slide making clamp

A thin-layer cell and centrifugal technology, which is applied in the field of film-making clamps for centrifugal liquid-based thin-layer cell film machines, can solve the problem of exfoliated cells that are difficult to coat evenly, which affects the observation, analysis and diagnosis of pathologists, and glass slides Blurred background and other problems, to achieve the effect of clear background

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

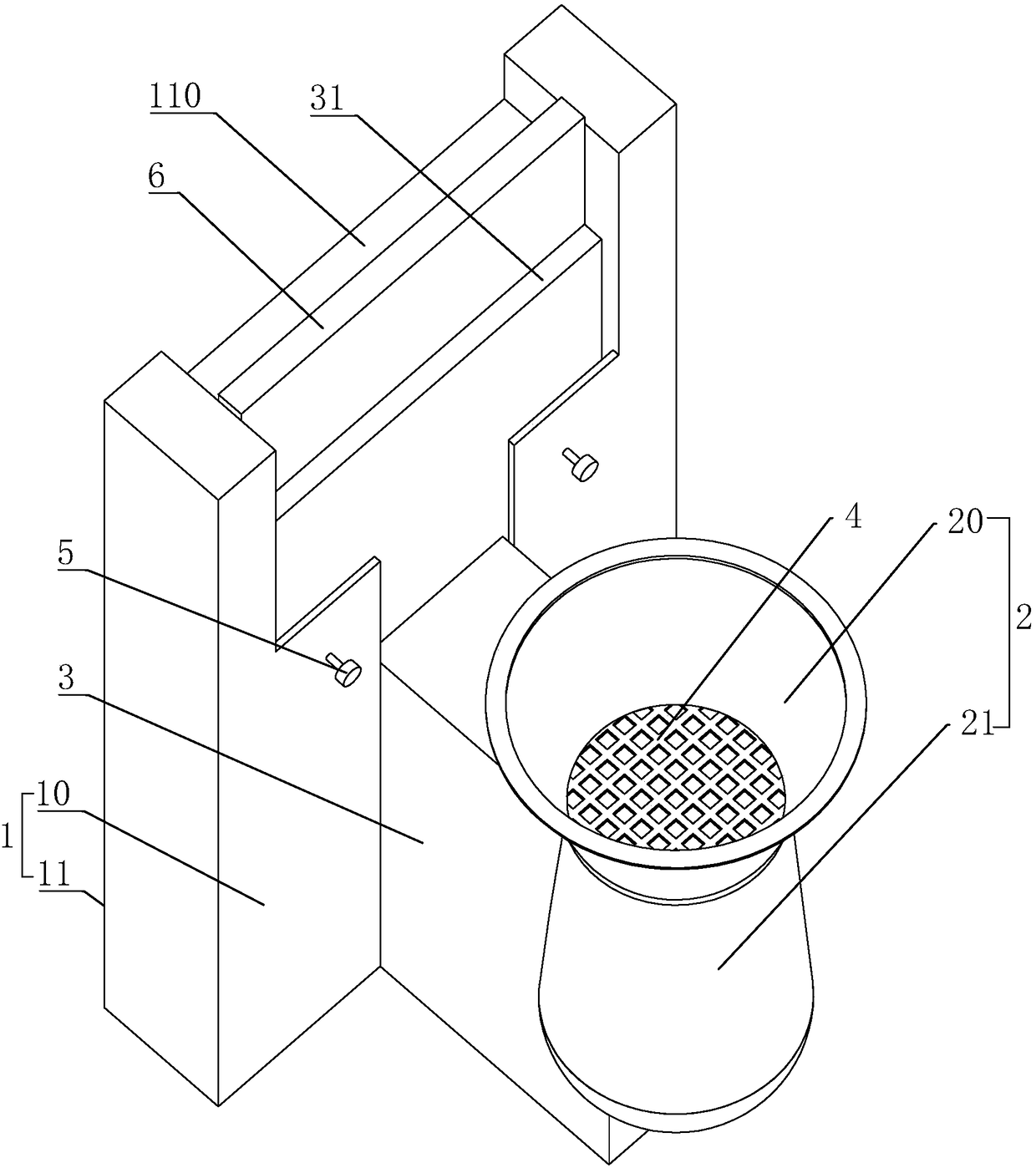

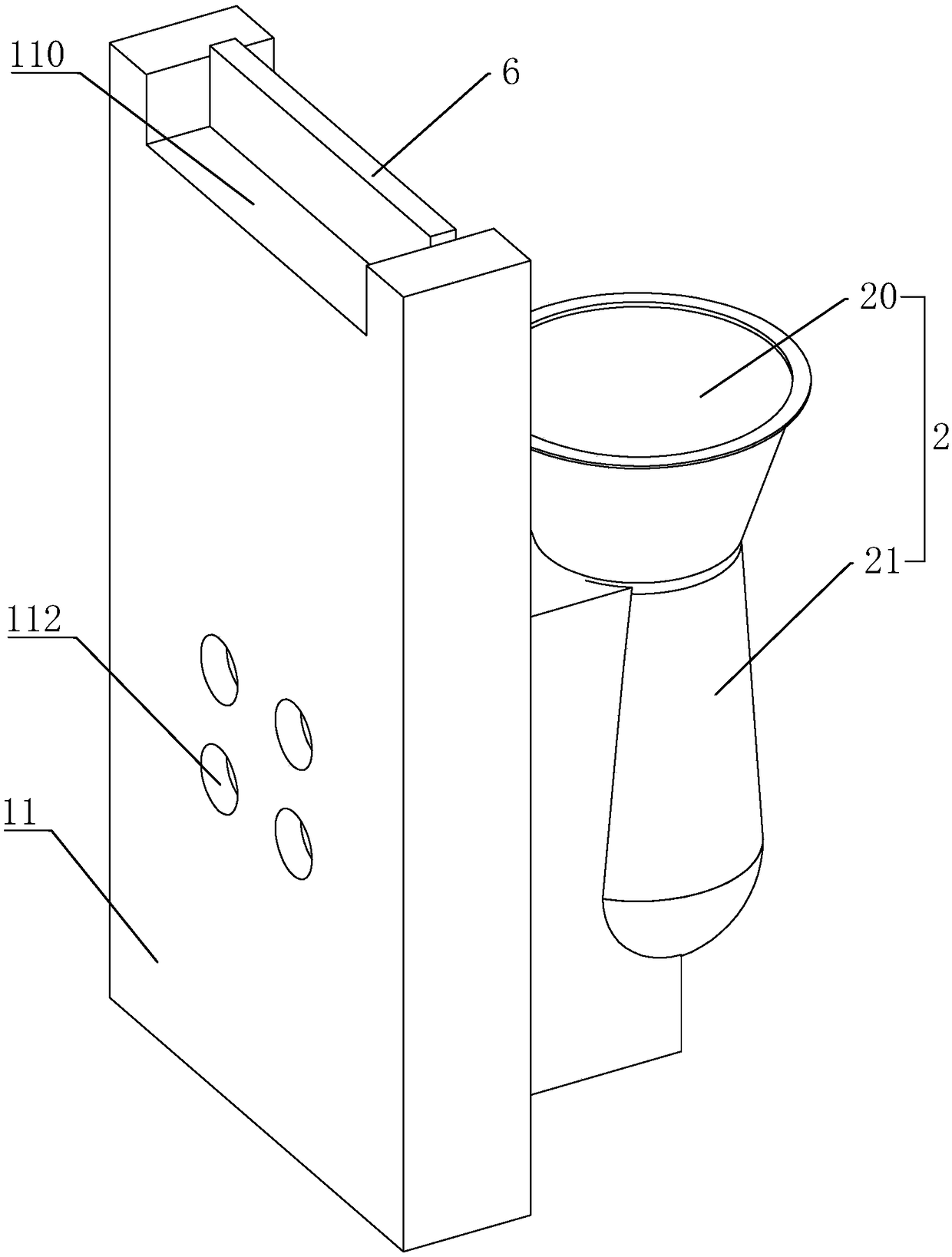

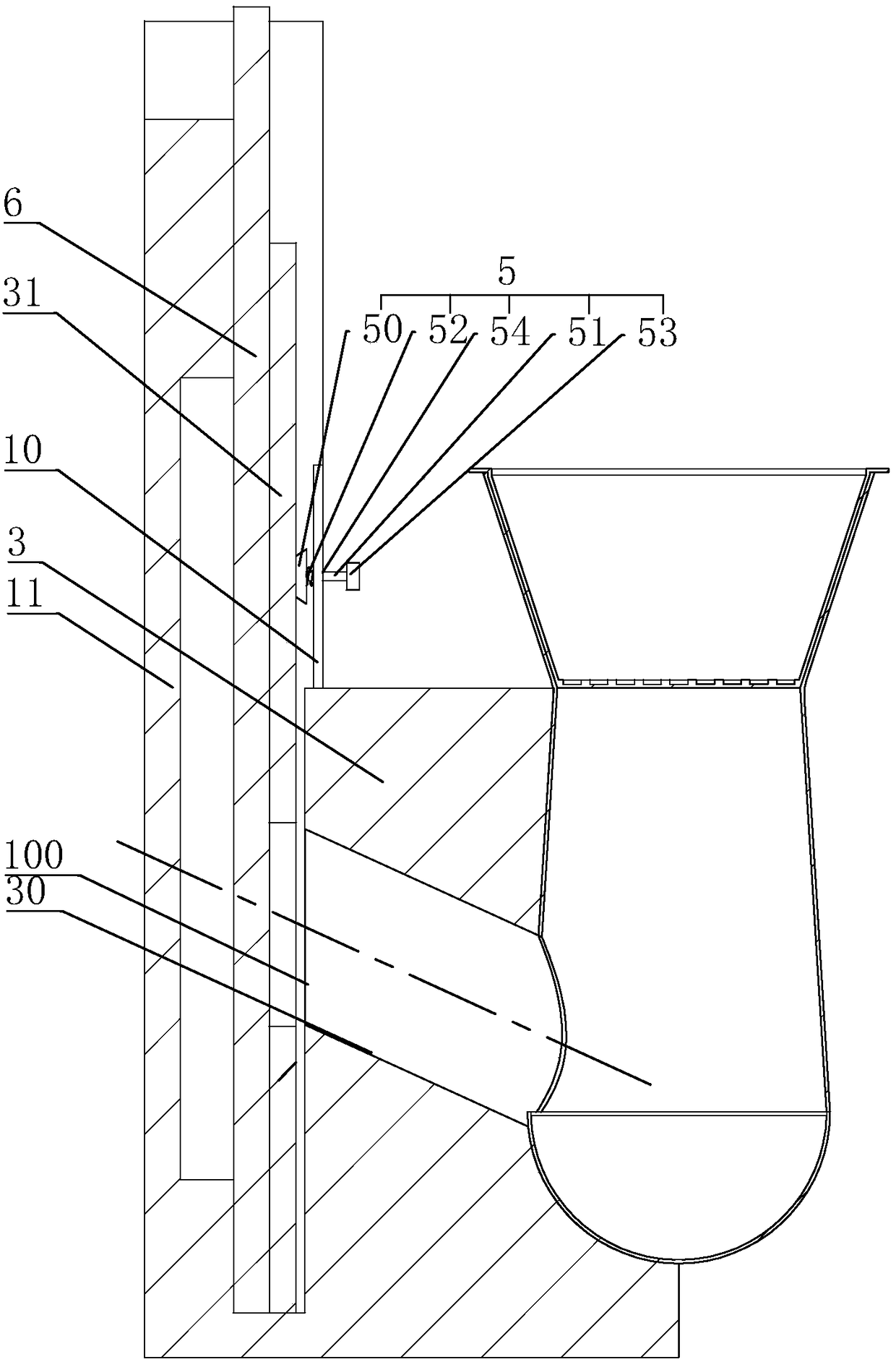

[0025] Embodiment 1: A kind of film-making clip for centrifugal liquid-based thin-layer cell film-making machine, refer to figure 1 , figure 2 , including a box body 1 for clamping slides 6 , the box body 1 includes a front side plate 10 , a rear side plate 11 and a bottom plate for connecting the front side plate 10 and the rear side plate 11 . A downwardly recessed U-shaped notch 110 is provided on the upper edge of the rear side plate 11 , and the upper edge of the front side plate 10 is lower than or equal to the height of the bottom of the U-shaped notch 110 . This is convenient for the staff to pinch out the slide glass 6 from the box body 1 .

[0026] combine image 3 1. On the front side plate 10, there are transparent coating holes 100 corresponding to the positions where the slide glass 6 needs to be coated with the sample solution. A liquid storage hopper 2 for adding sample liquid is provided at a position opposite to the box body 1. The liquid storage hopper 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com