Microfluidic paper chip array, preparation method and application thereof

A microfluidic paper chip and paper chip technology, which is applied in the direction of analyzing materials through chemical reactions, and analyzing materials through observation of the influence of chemical indicators, to achieve accurate results, promote applications, and high detection sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Example 1 Preparation of microfluidic paper chip array

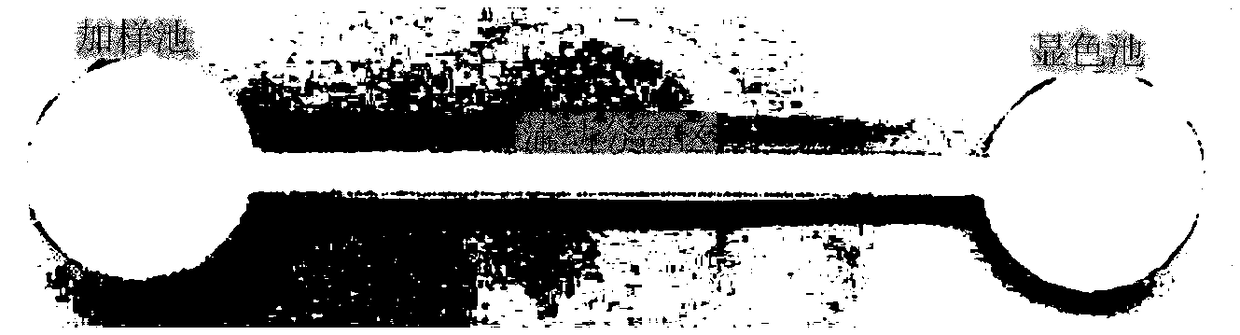

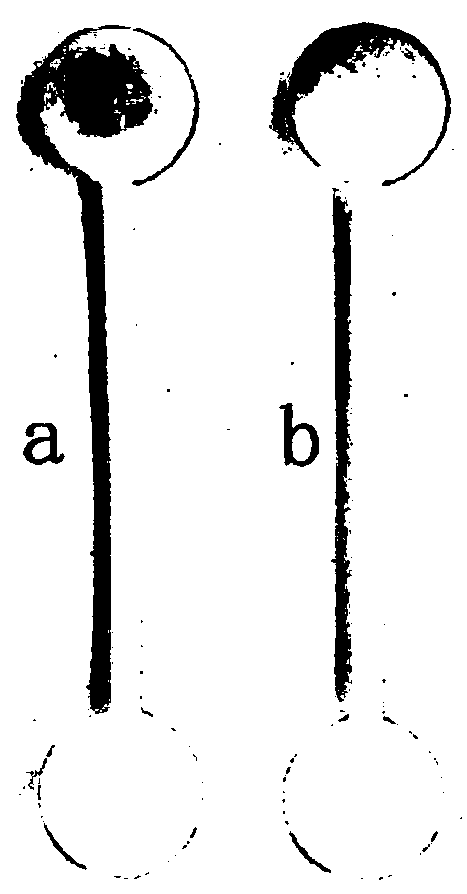

[0052] 1) Use Microsoft Word 2010 software to design the shape of the paper chip. The total length of the flow channel is 36mm, the width is 2mm, and the radius of the circular paper chip at both ends of the channel is 2mm. Outlines were printed on Whatman No. 1 cellulose chromatography paper, and paper chips were cut out. like figure 1 shown. The paper chip is easy to process and has a complete shape. Five paper chips are prepared to form a microfluidic paper chip array.

[0053] 2) Preparation of reagents:

[0054] 0.001mol / L methyl red: Weigh 0.014g of methyl red into a 50mL beaker, add absolute ethanol to dissolve, and dilute to 50mL with water, set aside;

[0055] 0.001mol / L neutral red: Weigh 0.014g of neutral red into a 50mL beaker, add absolute ethanol to dissolve, and dilute to 50mL with distilled water, set aside;

[0056] 0.001mol / L Bromocresol Violet: Weigh 0.027g of Bromocresol Violet into a 50mL...

Embodiment 2

[0061] Example 2 Preparation of microfluidic paper chip array

[0062] 1) Use CAD2008 software to design the shape of the paper chip. The total length of the flow channel is 20 mm, the width is 1 mm, and the radius of the circular paper chip at both ends of the channel is 5 mm. Outlines were printed on Whatman No. 1 cellulose chromatography paper, and paper chips were cut out. The paper chip is easy to process and has a complete shape. Five paper chips are prepared to form a microfluidic paper chip array.

[0063] Preparation of reagents:

[0064] 0.001mol / L methyl red: Weigh 0.014g of methyl red into a 50mL beaker, add appropriate amount of absolute ethanol to dissolve, and dilute to 50mL with distilled water, set aside;

[0065] 0.001mol / L neutral red: Weigh 0.014g of neutral red into a 50mL beaker, add an appropriate amount of absolute ethanol to dissolve, and dilute to 50mL with distilled water for later use;

[0066] 0.001mol / L Bromocresol Violet: Weigh 0.027g of Bromo...

Embodiment 3

[0070] Embodiment 3 Obtaining method of matrix X

[0071] Take 2g of fresh pork, add 2mL of pure water, grind for 5min; grind into a homogenous slurry. Take the paper chip array prepared by the method in Example 2, take pictures with a camera, and perform white balance correction before taking pictures.

[0072] Slowly add 60 μL of the homogenate dropwise to the sample pool, and the liquid flows from the sample pool to the chromogenic pool along the channel. When the liquid enters the chromogenic pool 300s, take a picture.

[0073] Process the paper photos with the software Image-Pro Plus 6.0 to obtain the Δ in the area T R, Δ T G, Δ T B value (such as Figure 7 shown). Subtract the R, G, and B values after detection from the R, G, and B values before detection to obtain ΔR, ΔG, and ΔB, and finally obtain the sum of the changes in ΔR, ΔG, and ΔB values of all pixels in the chromogenic pool area Δ T R, Δ T G, Δ T B is the matrix X, and the result is as follows: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com