Method for preparing carboxyl functionalized gold nano core-shell structure MOF-5

A technology of MOF-5 and carboxyl functionalization, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem that the photothermal treatment effect of gold nanoparticles cannot be well realized, and the reduction of nanoparticle Yield, cumbersome synthesis steps and other problems, to achieve the effect of increasing yield, improving universality, and good preparation repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

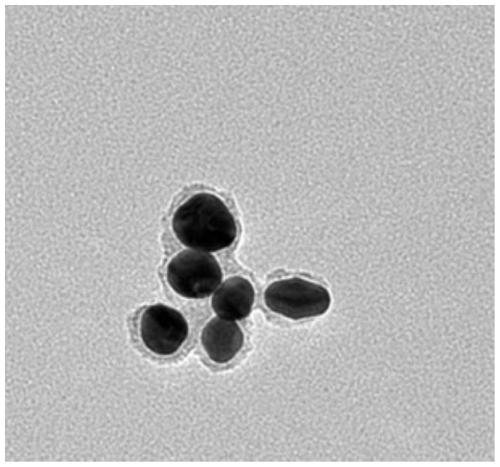

Image

Examples

Embodiment 1

[0022] A method for preparing carboxyl-functionalized gold nano-core-shell MOF-5, characterized in that it comprises the following steps:

[0023] (1), prepare the reaction substrate: zinc nitrate hexahydrate Zn(NO 3 ) 2 ·6H 2 O, 1,2,4-benzenetricarboxylic acid (C 9 h 6 o 6 ), polyvinylpyrrolidone PVP, N,N dimethylformamide mixed with alcohol, chloroauric acid HAuCl 4 The reaction substrate is obtained by mixing according to a certain mass ratio; the above mass ratio is 145:30:1820-10920:60000-80000:0.5-8.

[0024] (2), the obtained reaction substrate is fully dissolved in the reaction vessel to form a transparent, uniform and stable liquid;

[0025] (3), take out a certain amount of said liquid, join in hydrothermal kettle or other container that can carry out solvothermal reaction;

[0026] (4), the above-mentioned liquid is reacted at a temperature of 100-150° C. for 1-48 hours;

[0027] (5), after the reaction finishes, cool naturally to room temperature, centrifug...

Embodiment 2

[0030] A method for preparing carboxyl-functionalized gold nano-core-shell MOF-5, characterized in that it comprises the following steps:

[0031] (1), prepare the reaction substrate: zinc nitrate hexahydrate Zn(NO 3 ) 2 ·6H 2 O, 1,2,4-benzenetricarboxylic acid (C 9 h 6 o 6 ), polyvinylpyrrolidone PVP, N,N dimethylformamide mixed with alcohol, chloroauric acid HAuCl 4 The reaction substrate is obtained by mixing according to a certain mass ratio; the above mass ratio is 145:30:5280-8940:60000-80000:0.5-8.

[0032] (2), the obtained reaction substrate is fully dissolved in the reaction vessel to form a transparent, uniform and stable liquid;

[0033] (3), take out a certain amount of said liquid, join in the hydrothermal kettle;

[0034] (4) The above liquid was reacted for 3 hours at a temperature of 140°C;

[0035] (5), after the reaction is finished, cool naturally to room temperature, centrifuge at a speed of 10000-30000r / min to obtain a gold nano-core-shell structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com