A method for calculating the amount of permanent magnets of a permanent magnet motor

A technology of permanent magnet consumption and permanent magnet motor, which is applied in the field of permanent magnet consumption calculation of permanent magnet motor, and can solve problems such as waste of resources and cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A method for determining the air gap of a permanent magnet motor, taking a TYCKK400-4 (6kV 400kW) motor as an example, the specific steps include:

[0053] 1. According to the basic theory of electromechanics and the motor design manual, the back EMF is determined to be 6400V, the maximum air gap and the minimum air gap are 9mm and 6mm respectively, the length of the stator core is 462.5mm, and the length of the rotor core is 462.5mm. The magnetic permeability of the rotor is 6600 and 1600, the inner and outer diameters of the stator are 670mm and 423mm respectively, and the shaft diameter of the rotor is 150mm, which makes it effective and feasible in the design direction of ordinary asynchronous motors.

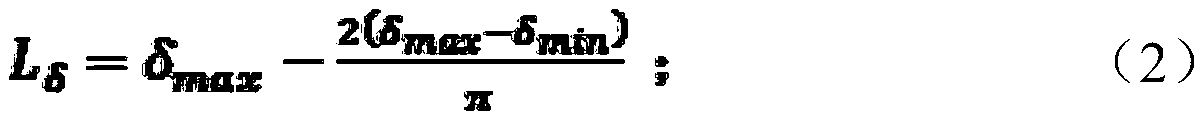

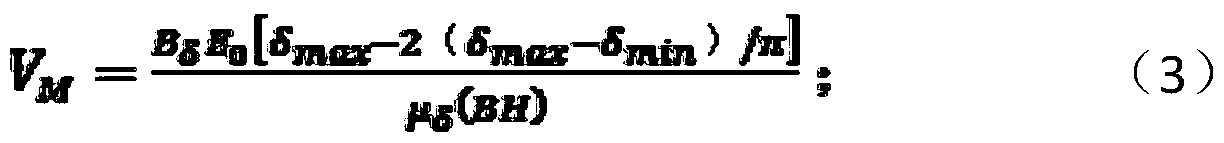

[0054] 2. According to the formula (1), it is determined that the outer diameter of the rotor is 408mm; the average air gap length parameter is used here, and those skilled in the art can assign values according to the actual situation; for the permanent magnet moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com