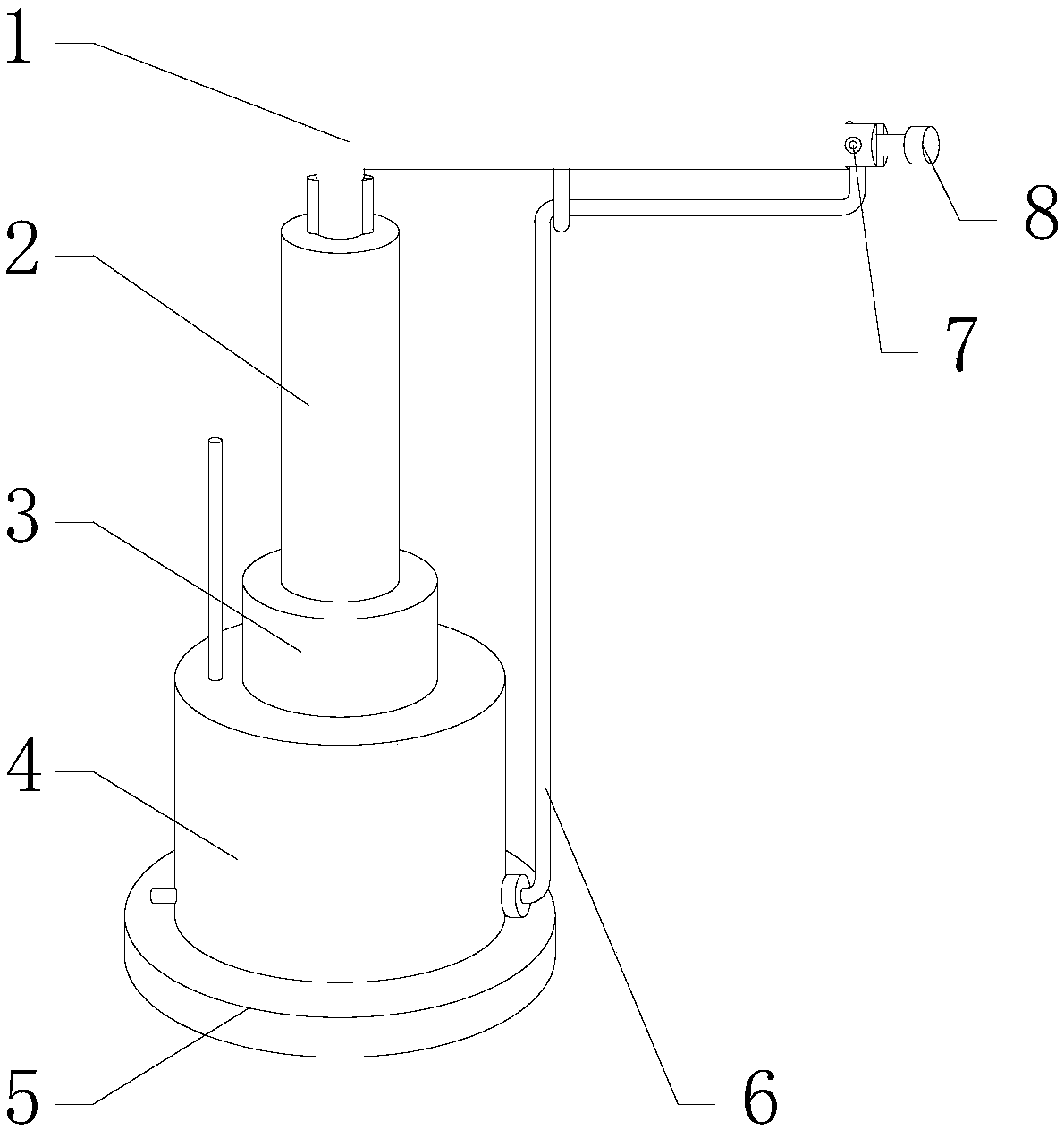

Rotation sprayer structure for paint spraying robot

A technology of rotating nozzles and robots, applied in the direction of spraying devices, etc., can solve the problems of small spraying range and poor use effect, and achieve the effect of expanding the spraying range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

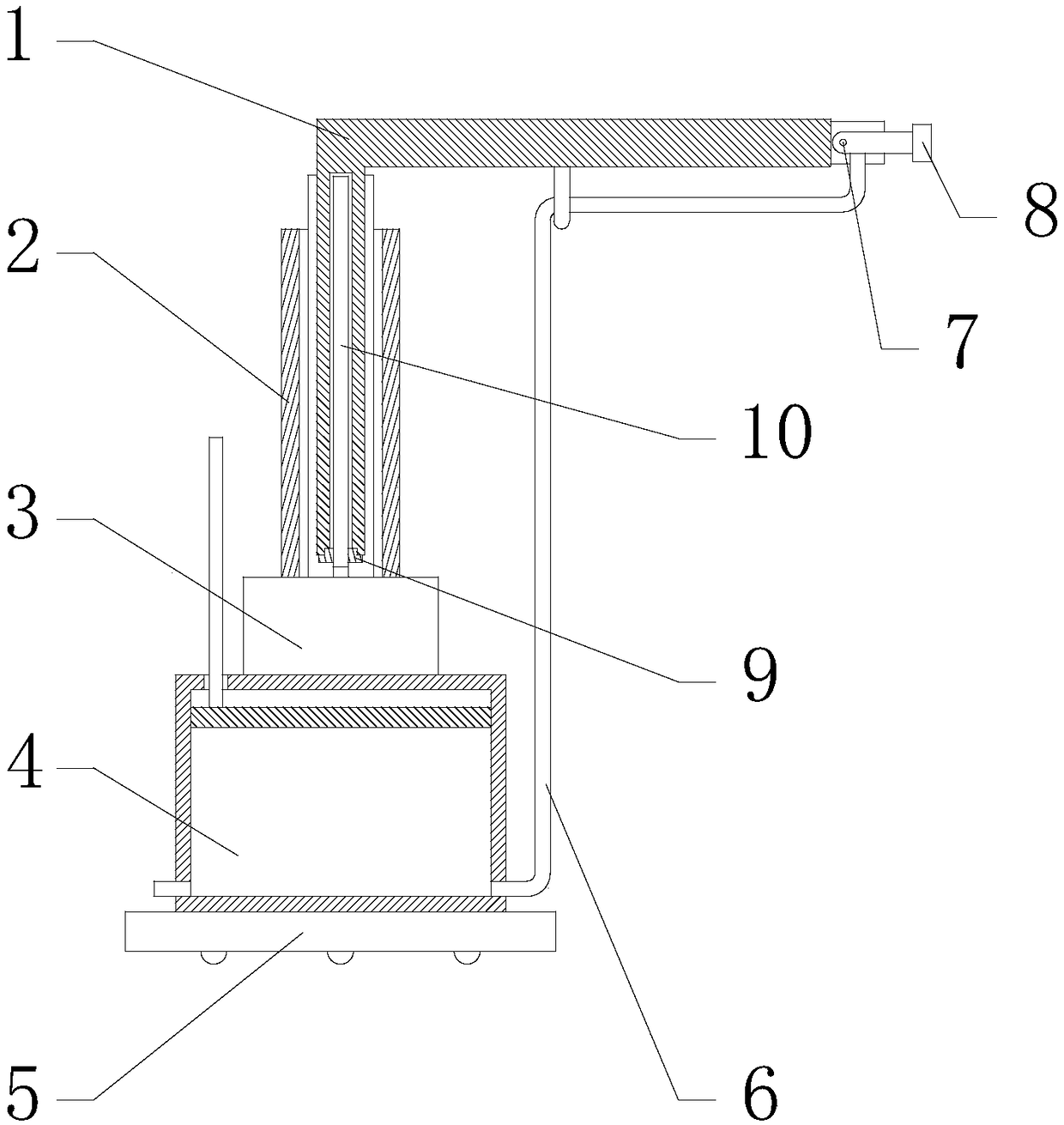

specific Embodiment approach

[0019] Specific implementation method: in actual use, the user holds the rotating rod 7 and rotates counterclockwise, and the rotating rod 7 rotates to drive the nozzle 8 to rotate, so as to realize the nozzle 8 facing upwards. If the rotating rod 7 is rotated counterclockwise, then Realize the downward rotation of the nozzle 8. When the nozzle 8 rotates to the designated direction, the user holds the rotation rod 7 and the nut respectively, and rotates the nut, and then the nut rotates and moves inward, thereby the L-shaped telescopic rod 1 The top is tightened to fix the rotating rod 7, and then the user opens the switch connecting the motor 3 and the external power supply to realize the circuit connection between the motor 3 and the external power supply, and then the motor 3 works to drive the screw rod 10 to rotate, and then the screw rod 10 rotates to drive the nut seat 9 to move upward along the screw rod 10, and the upward movement of the nut seat 9 drives the L-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com