Ink fountain

A technology of ink fountain and middleware, which is applied in the direction of printing, printing machines, general parts of printing machinery, etc., can solve the problems of reduced clamping force and difficult cleaning of clamping slats, and achieve the effect of reducing clamping force and avoiding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

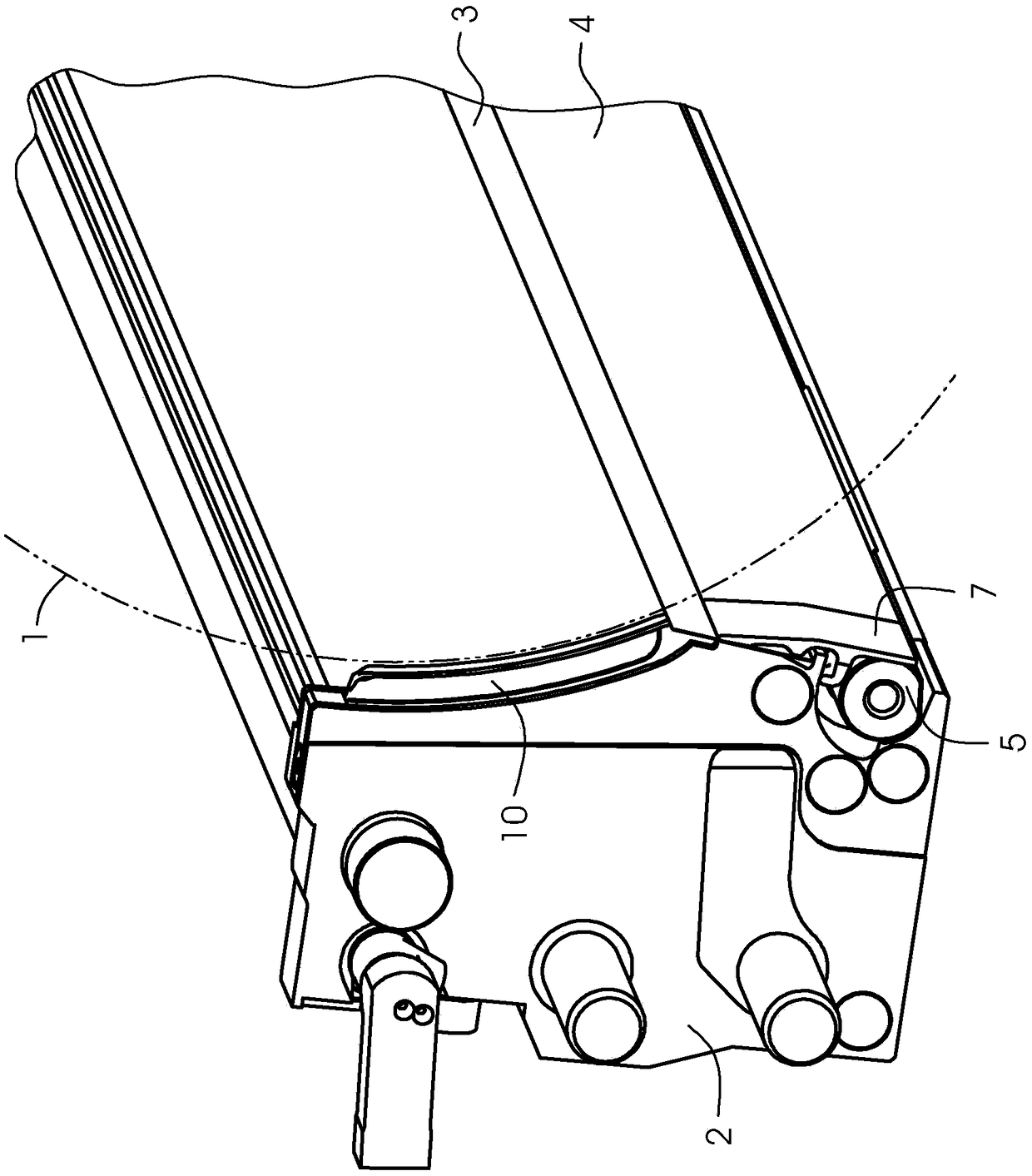

[0016] figure 1 Shows the components of the anilox inking mechanism of a printing press for offset printing. Shown is an anilox roller 1 and an ink fountain 2 with a doctor blade 3 which rests against the anilox roller 1 . The anilox roller 1 is only indicated by phantom lines and only a part of the ink fountain 2 is shown. A clamping strip 4 extends parallel to the scraper 3 for clamping the scraper 3 on the ink fountain. The clamping strip 4 is configured as a rocker and is actuated during clamping by means of an eccentric shaft 5 . One lever arm of the clamping strip 4 bears against the eccentric shaft 5 , while the other lever arm presses against the scraper 3 .

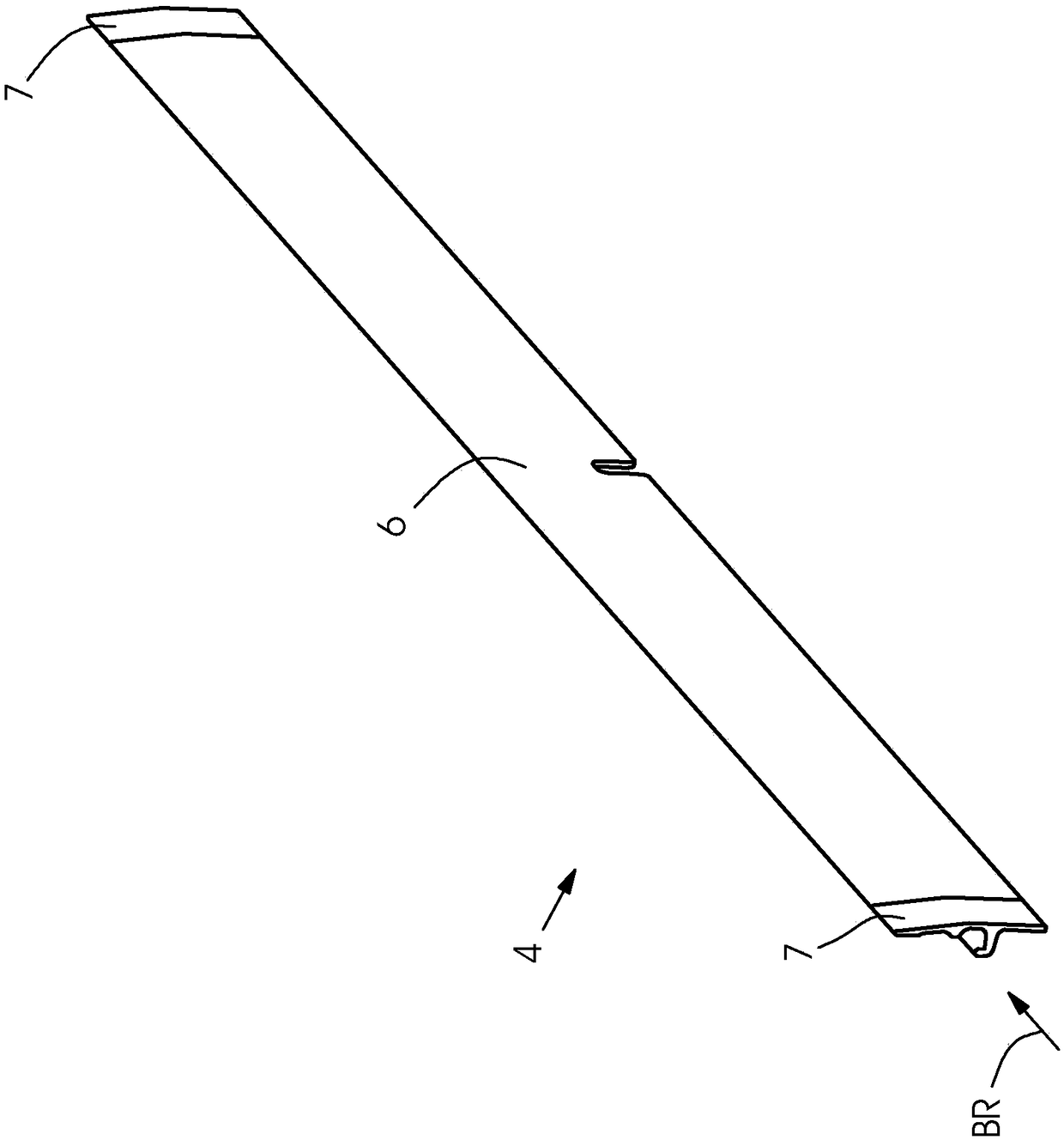

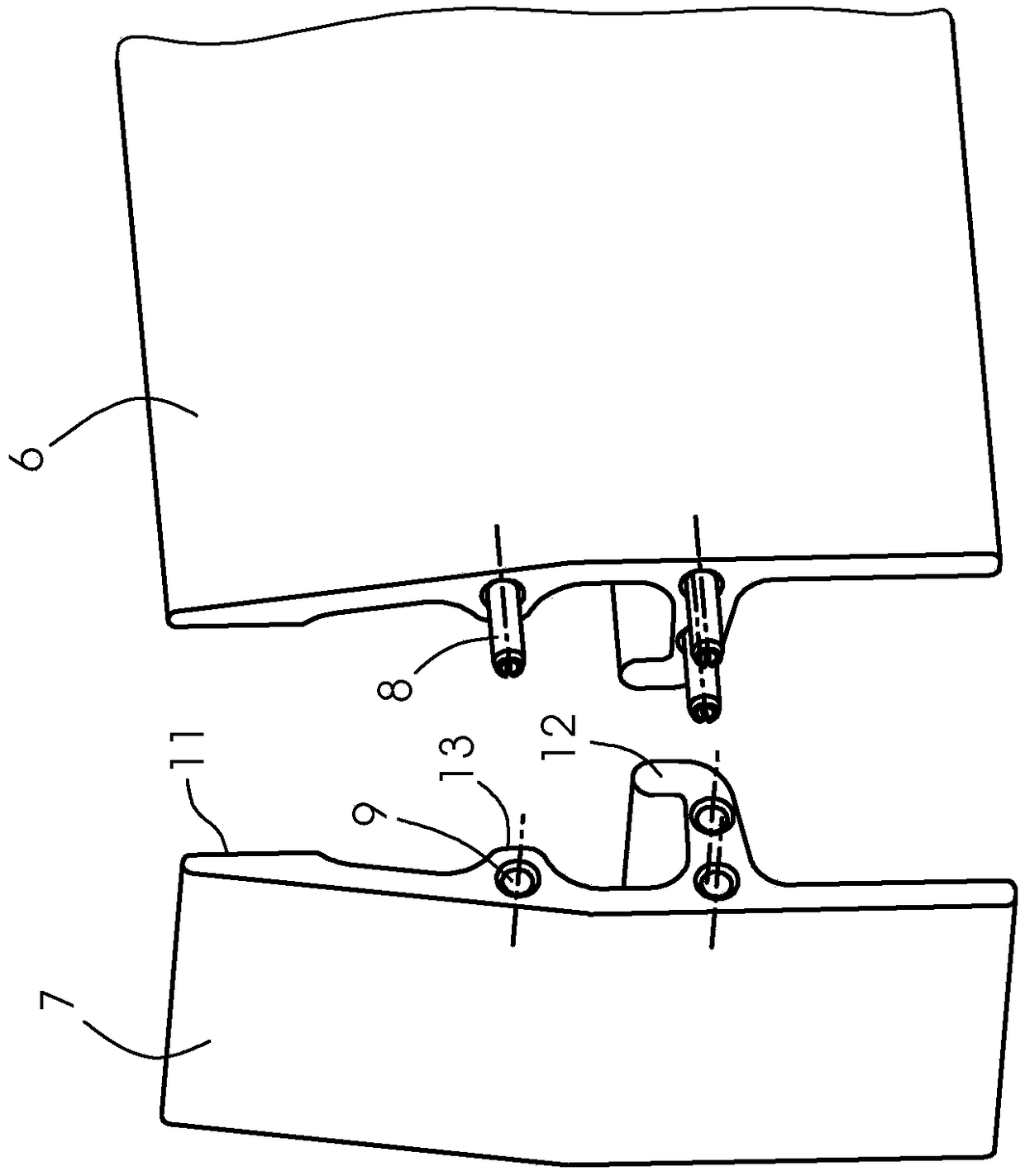

[0017] figure 2 It is shown that the clamping strip 4 comprises two end pieces 7 and a middle piece 6 located between them. The intermediate part 6 is arranged between the two end parts 7 parallel to the axis of rotation of the anilox roll 1 (as viewed according to the viewing direction BR). These end piec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com