Waste ink storage mechanism and inkjet recording device including same

A technology of waste ink and ink, applied in printing and other directions, can solve the problem of false detection of waste ink box and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be described below with reference to the drawings.

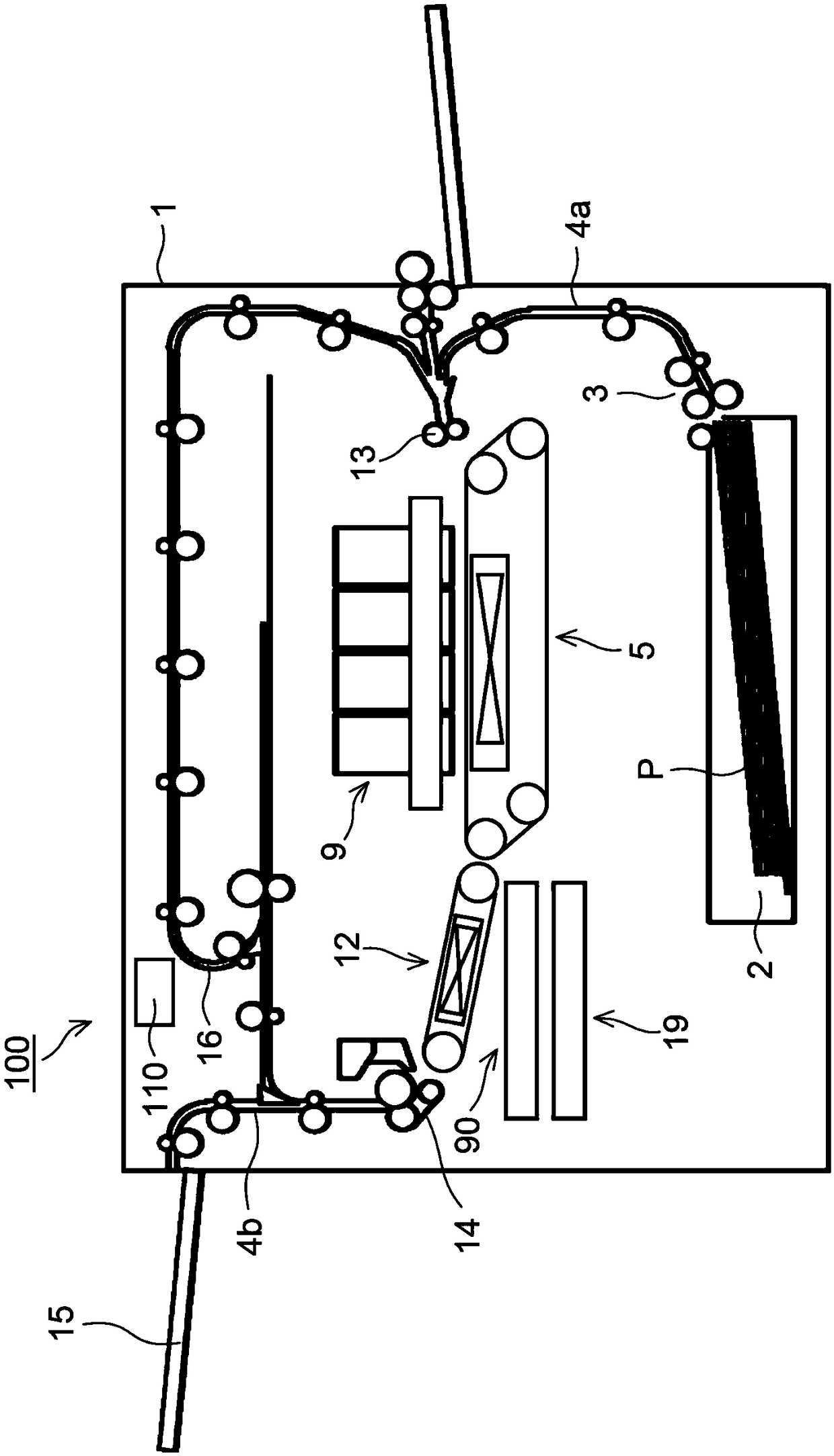

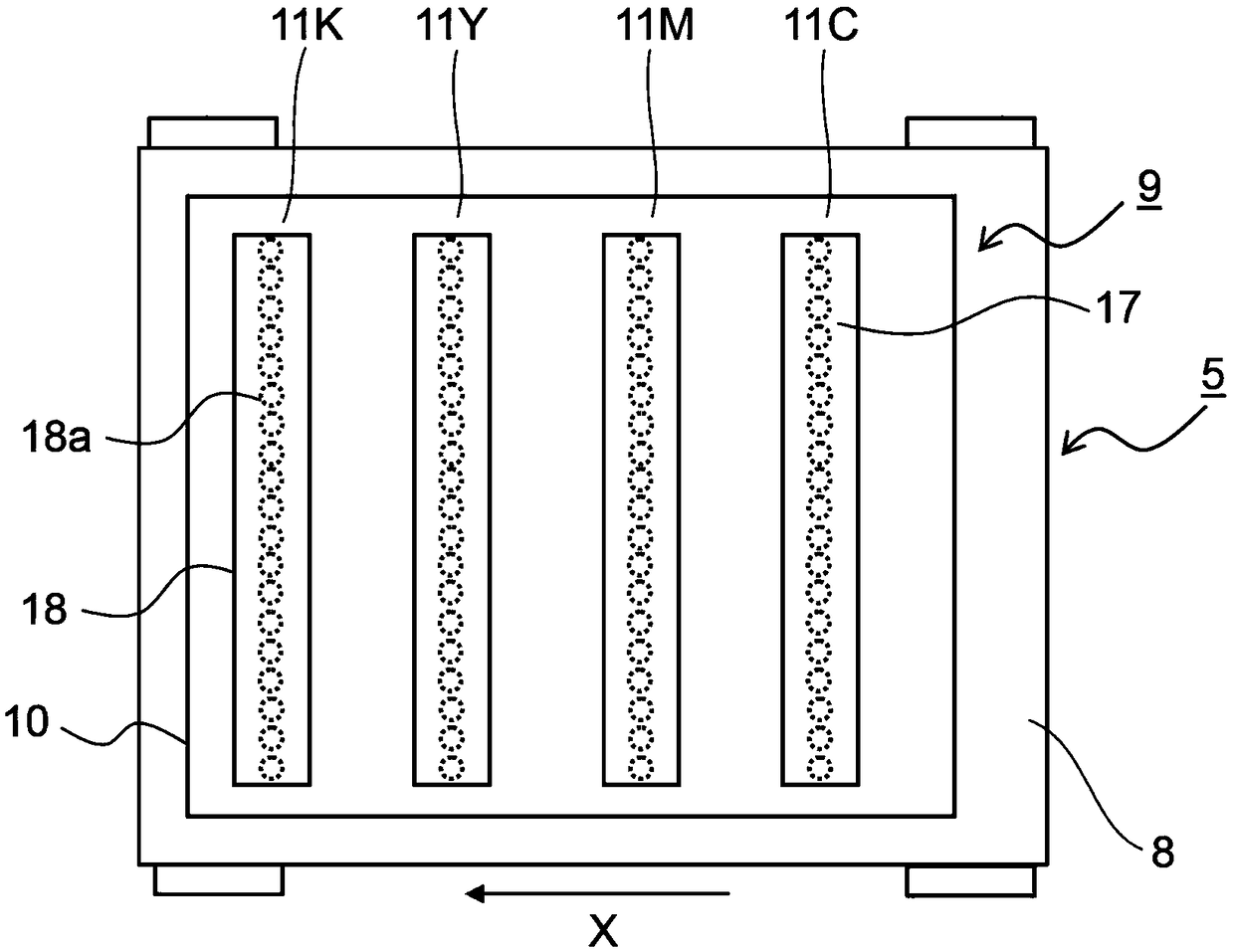

[0027] refer to Figure 1 to Figure 11 An inkjet recording device 100 according to an embodiment of the present invention will be described. like figure 1 As shown, in the inkjet recording apparatus 100 , a paper feeding cassette 2 , which is a paper storage portion, is arranged below the inside of the apparatus main body 1 . Paper P, which is an example of a recording medium, is stored in the paper feeding cassette 2 . Downstream of paper feed direction for paper feeder 2, i.e. figure 1 Above the right side of the paper feeding cassette 2 in the middle, a paper feeding device 3 is arranged. Using the paper feeding device 3, the paper P is figure 1 Towards the upper right of the paper feeder 2, separate and send out one by one.

[0028] In addition, the inkjet recording apparatus 100 is provided with a first paper transport path 4a inside. The first paper feeding path 4...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap