Base plate processing device

A substrate processing device and substrate technology, applied to measuring devices, optical devices, and devices for coating liquid on the surface, etc., can solve problems such as poor coating, damage to slit nozzles, and attenuation of light received by lasers, and achieve suppression of errors. Effects of detection, accuracy improvement, and burden reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings.

[0043] 1. The first embodiment

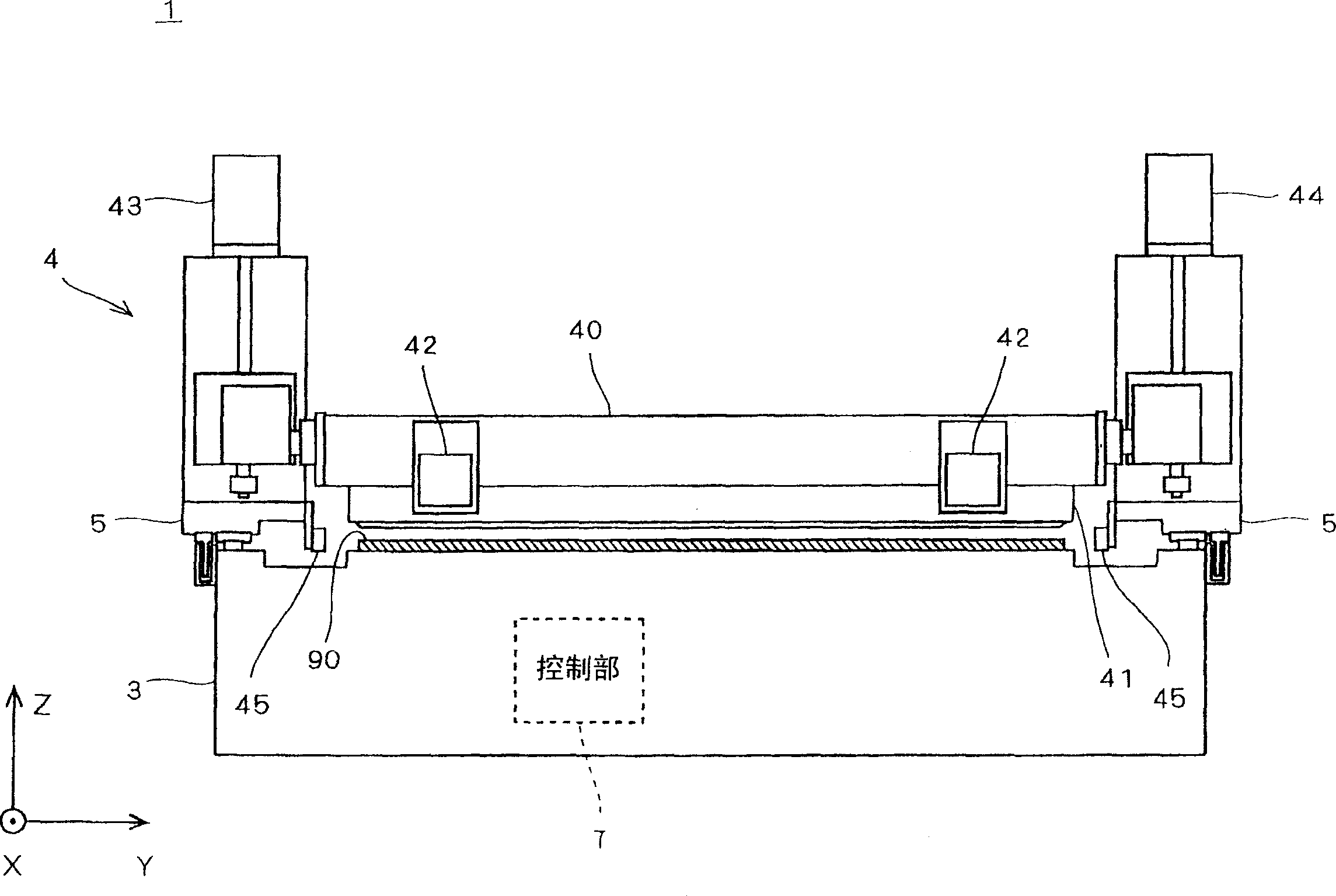

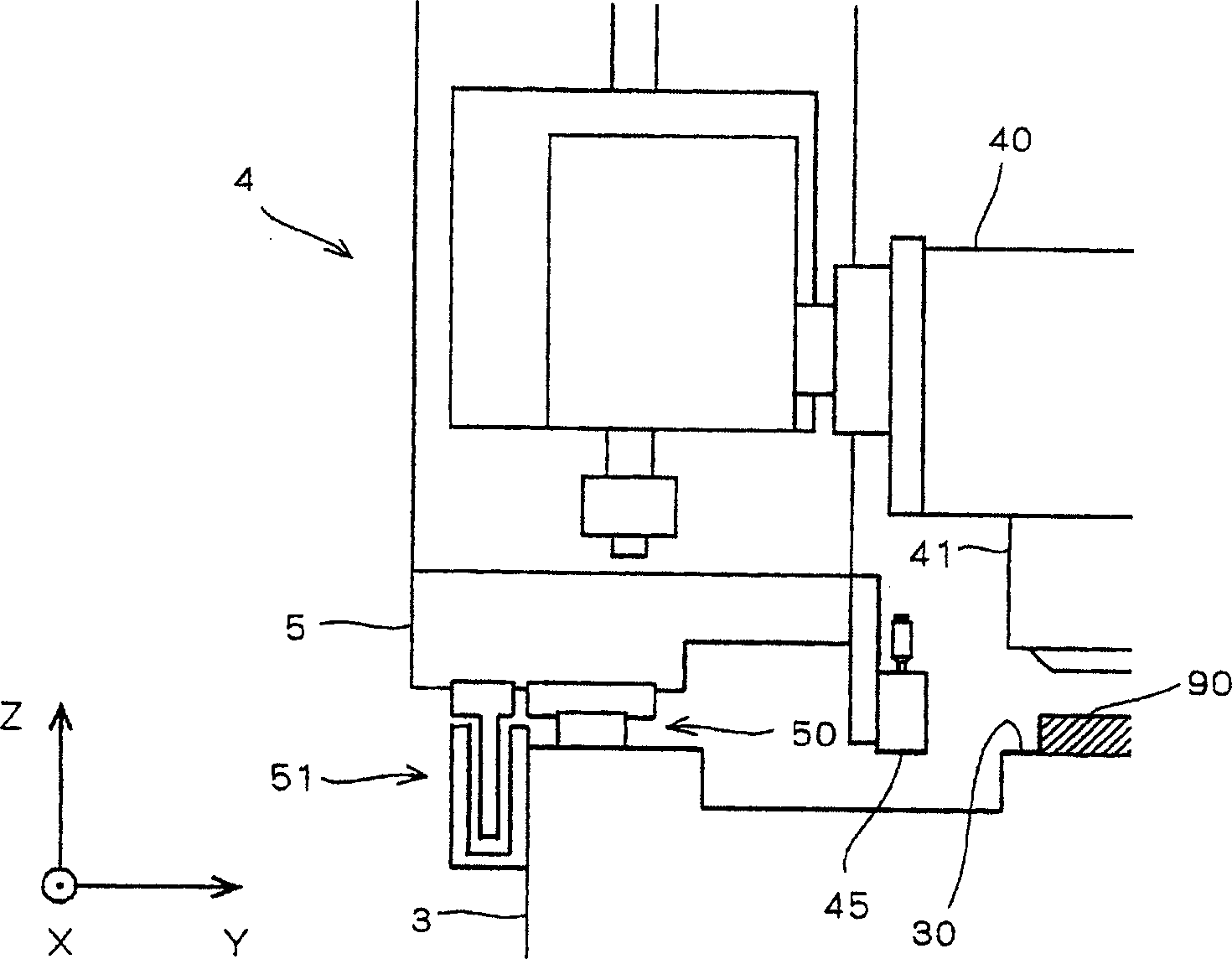

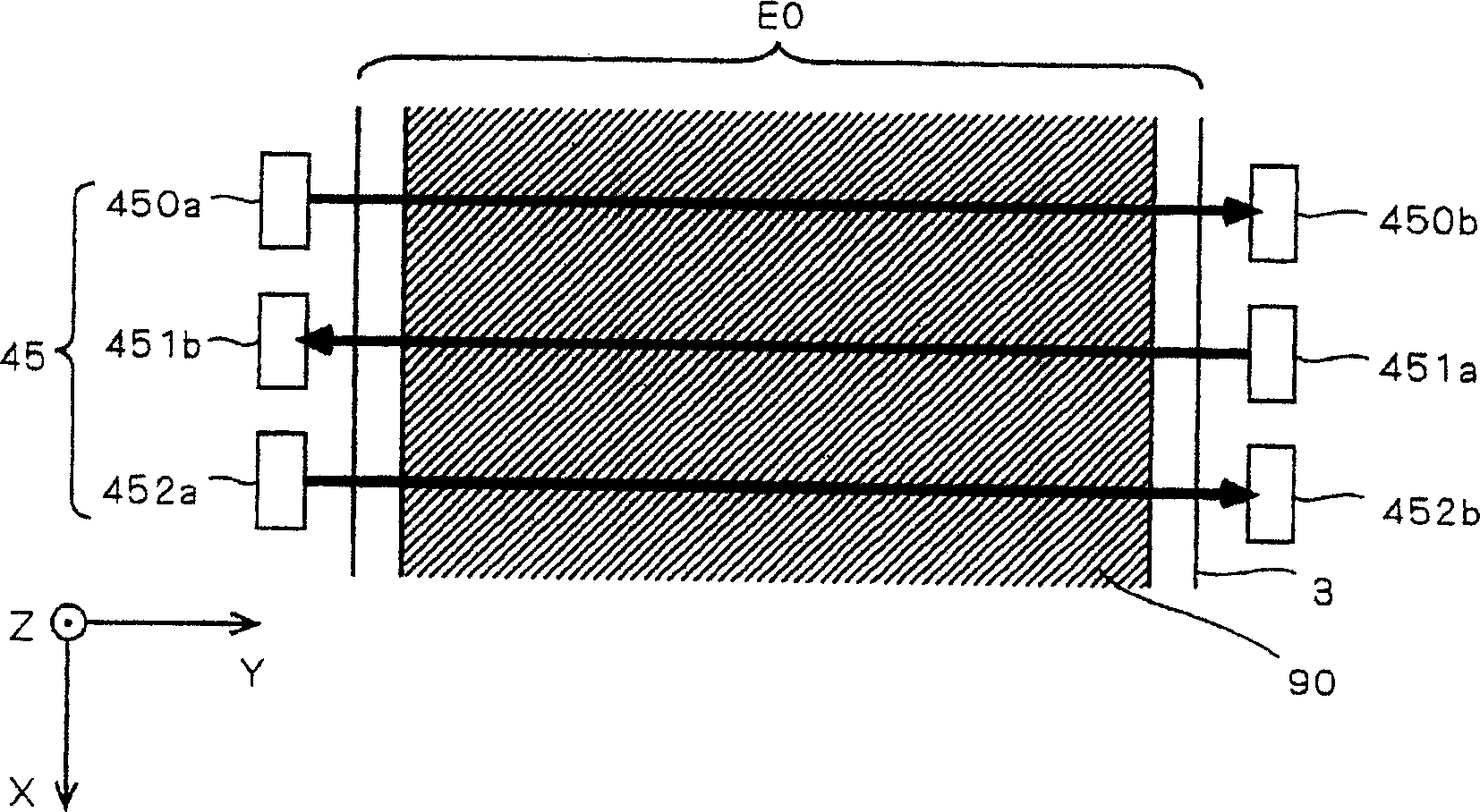

[0044] 1.1 Description of composition

[0045] figure 1 is a front view of the substrate processing apparatus 1 according to the first embodiment of the present invention, figure 2 It is an enlarged view of the peripheral portion of the detection unit 45 in the substrate processing apparatus 1 . In addition, in figure 1 and figure 2 In the diagram, for the convenience of illustration and description, the Z-axis direction represents the vertical direction, and the XY plane represents the horizontal plane. This is defined for the convenience of grasping the positional relationship, and does not limit the directions described below. The same applies to subsequent figures.

[0046] The substrate processing apparatus 1 is used as the substrate 90 in the process of selectively etching the electrode layer etc. form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com