A high-horsepower agricultural machinery

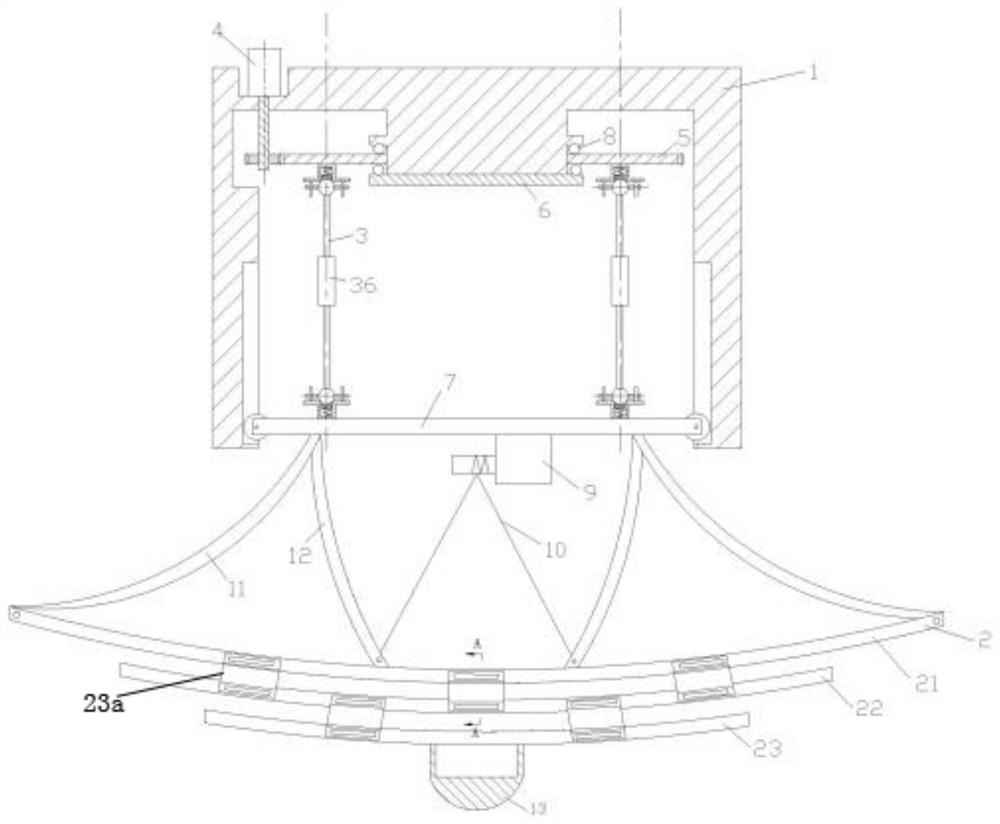

A technology of agricultural machinery and horsepower, applied in the direction of elastic suspension, vehicle parts, transportation and packaging, etc., can solve the problems of reduced driving stability, poor vibration damping performance, and inability to meet high-horsepower agricultural machinery, so as to improve stability, The effect of reducing the requirements of the road environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

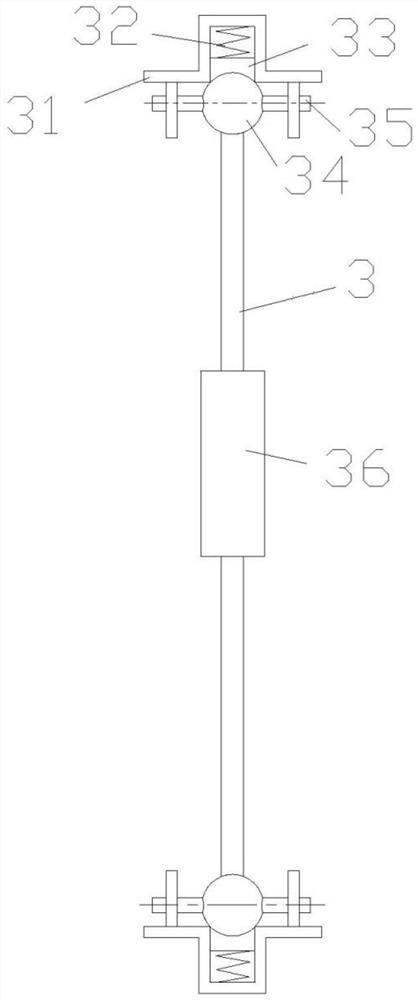

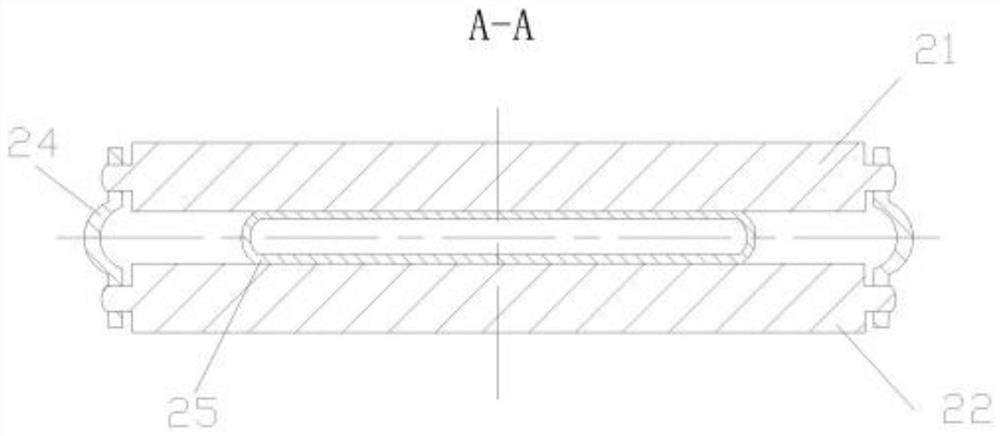

[0021] As an embodiment of the present invention, the height adjusting device 3 includes a housing 31, a spring 32, a graphite rod 33, a spherical shaft 34, a connecting shaft 35 and an elastic cylinder 36; There is a through hole; the spring 32 is installed in the groove of the housing 31; the spherical shaft 34 has a through hole, and the spherical shaft 34 passes through the through hole and the spherical shaft 34 on the shell wall on both sides of the housing 31 by the connecting shaft 35 The through hole on the top is connected by rotation, and the distance between the shell wall and the spherical surface on both sides of the shell 31 is 1 mm, mainly in order to reduce the force on the connecting shaft 35 and ensure that the spherical shaft can rotate flexibly; the graphite rod 33 is installed on the spherical shaft 34 and the spring Between 32, the contact surface between graphite rod 33 and spherical shaft 34 is a smooth arc surface, and graphite rod 33 has the effect of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com