A conveying device for furniture production

A technology for handling devices and furniture, applied in the direction of transportation and packaging, multi-axis trolleys, trolley accessories, etc., can solve problems such as unfavorable work, furniture slipping, inconvenient processing, etc., and achieve enhanced shock absorption, reduced bumps, and enhanced stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

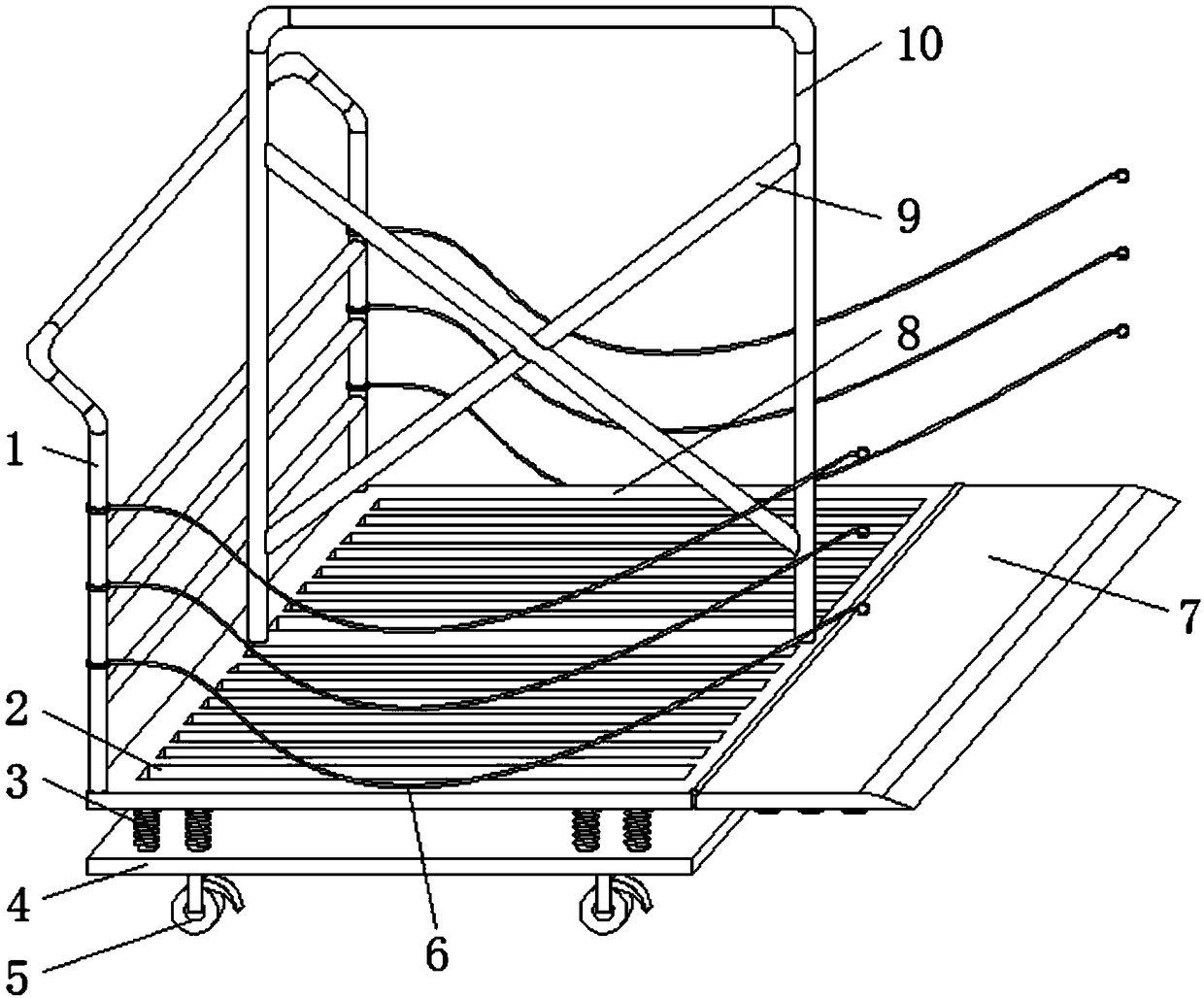

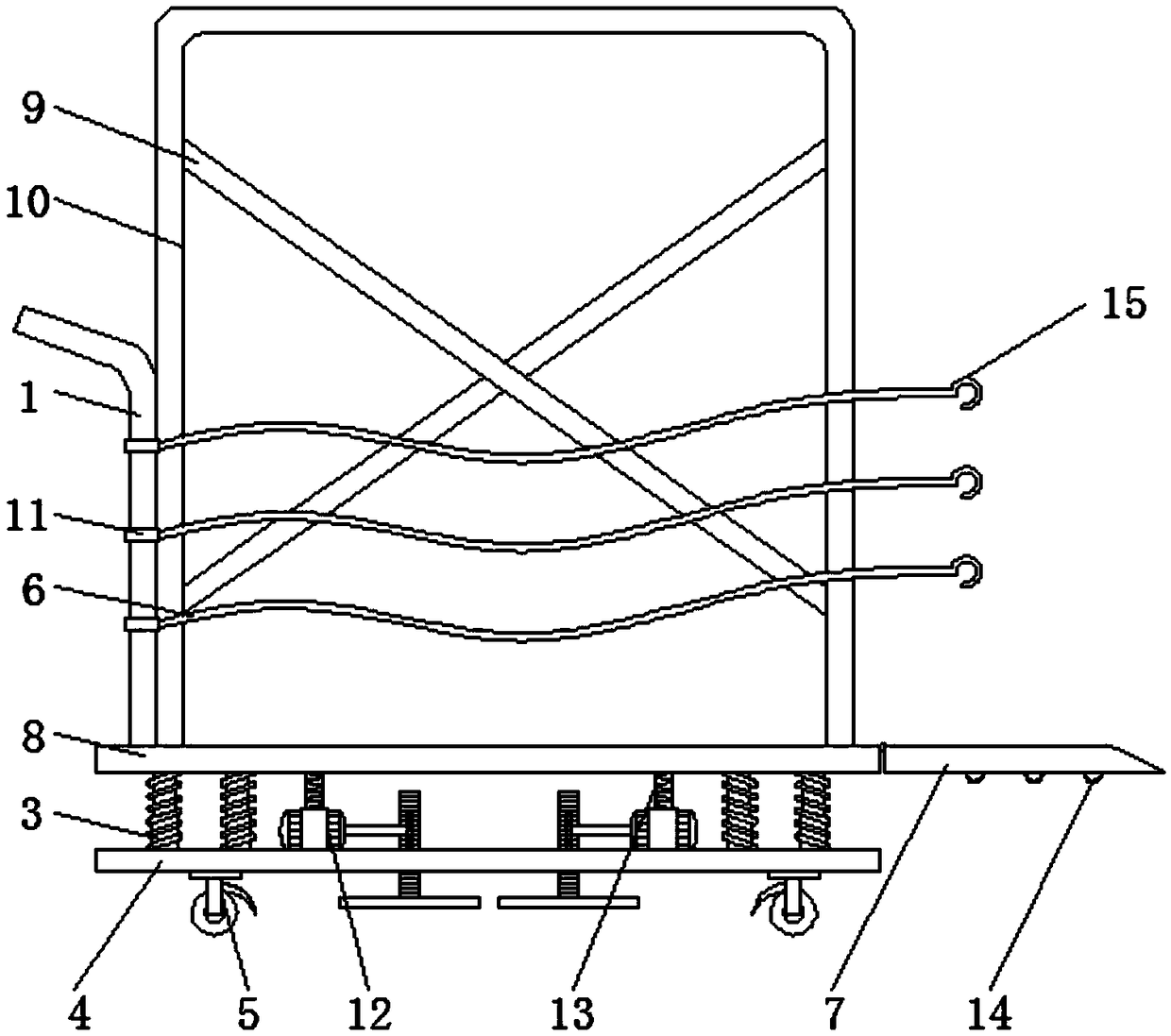

[0023] Embodiment one, with reference to Figure 1-2 , a carrying device for furniture production, comprising a carrying device body 8, a connecting rod 10 is welded at the top horizontal midline position of the carrying device body 8, a spacer 9 is welded inside the connecting rod 10, and the top side of the carrying device body 8 The push handle 1 is welded, the top of the handling device body 8 is equidistantly provided with a plurality of rectangular through holes 2, the spacer bar 9 has a cross-shaped structure, and the connecting rod 10 has an inverted U-shaped structure. This structure can not only realize the function of isolation, At the same time, it can reduce its own weight and is easy to move. The two ends of the push handle 1 are equidistantly connected to the elastic rope 6 through a plurality of hanging rings 11, and the other end of the elastic rope 6 is welded with a hook 15. The plate 7 is connected by rotation, and one side of the rotating plate 7 is symmet...

Embodiment 2

[0024] Embodiment two, refer to Figure 1-2 , the bottom of the handling device body 8 is connected with the base plate 4 through the first damping spring 3, four motors 12 are fixed at the top four corners of the base plate 4, and the tops of the four motors 12 are connected with the second damping spring 13. The handling device body 8 is connected, the bottom four corners of the base plate 4 are fixed with universal wheels 5, the first shock absorbing springs 3 are welded with four sets, and the four sets of first shock absorbing springs 3 are respectively located on the top four of the base plate 4. At the corner, and each set of first damping springs 3 is equidistantly welded with two, the second damping spring 13 can not only protect the motor 12 from being squeezed by the handling device body 8, but also combine the first damping spring 3 It can play the role of double shock absorption, enhance the shock absorption effect, thereby reducing the degree of bumping of the ha...

Embodiment 3

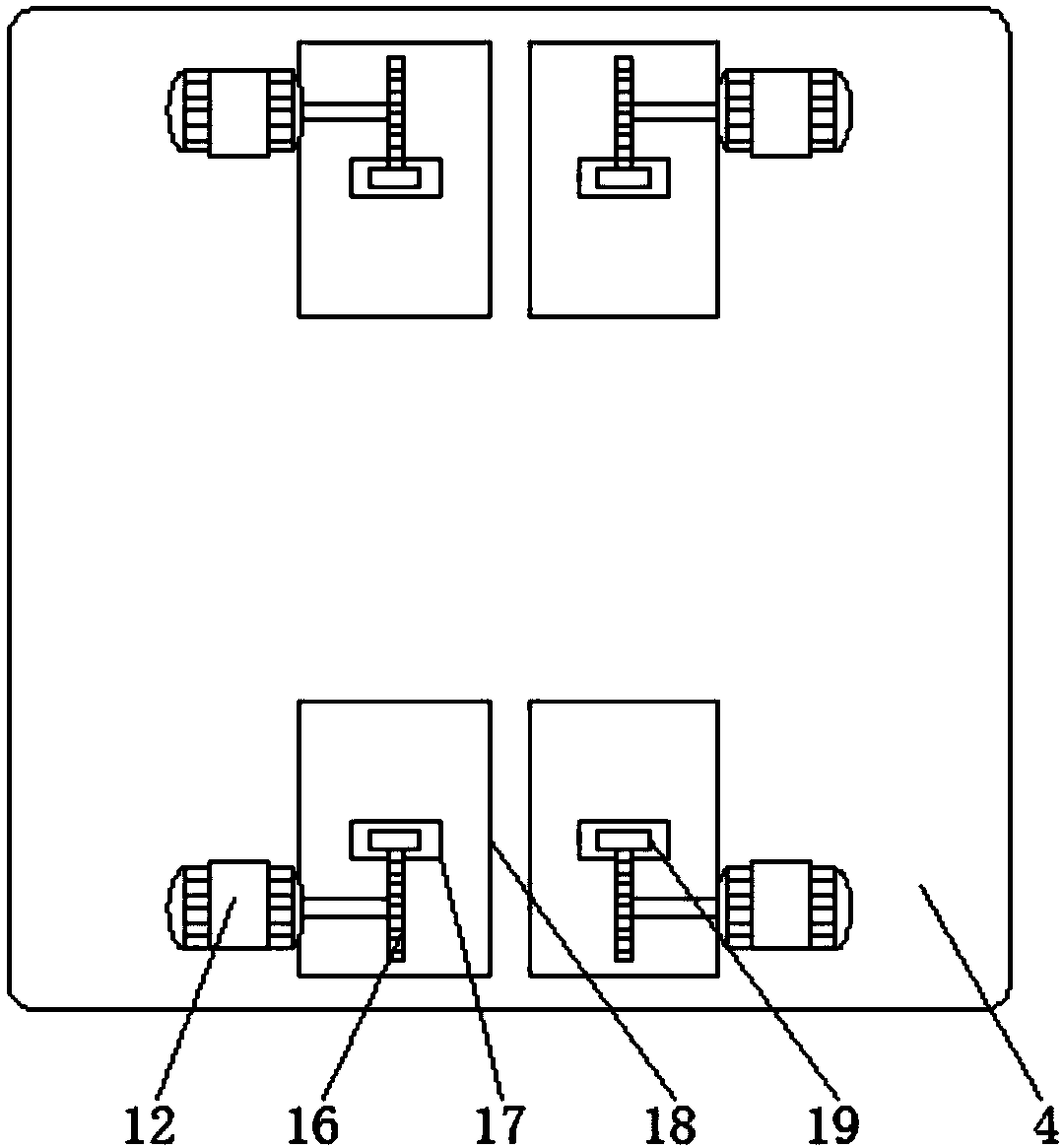

[0025] Embodiment three, refer to Figure 2-4 , the four motors 12 are all connected to the gear plate 16 through the rotating shaft. One side of the gear plate 16 is meshed with a gear bar 19. The top position of one side of the gear bar 19 is welded with a limit block 20, and the bottom of the gear bar 19 is welded with a The top of the support plate 18 and the bottom plate 4 are located on the outside of each gear bar 19, and a limit hole 17 is opened. The motor 12 drives the gear plate 16 to rotate to drive the gear bar 19 to move up and down, thereby driving the support plate 18 to move up and down to move the furniture. When reaching the top of the handling device, move the support plate 18 down to contact with the contact surface and hold up the universal wheel 5, which can enhance the stability of the handling device, thereby preventing the furniture from appearing in the process of moving to the handling device. The phenomenon of movement is conducive to the progress ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com