Construction method of joint freezing bottom sealing for ultra-deep foundation pit

A construction method and technology for deep foundation pits, which are applied in basic structure engineering, excavation, soil protection, etc., can solve the problems of deformation of steel cages, difficulty in lowering, and low depth of underground diaphragm walls, and achieve reduced depth of soil penetration, The effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

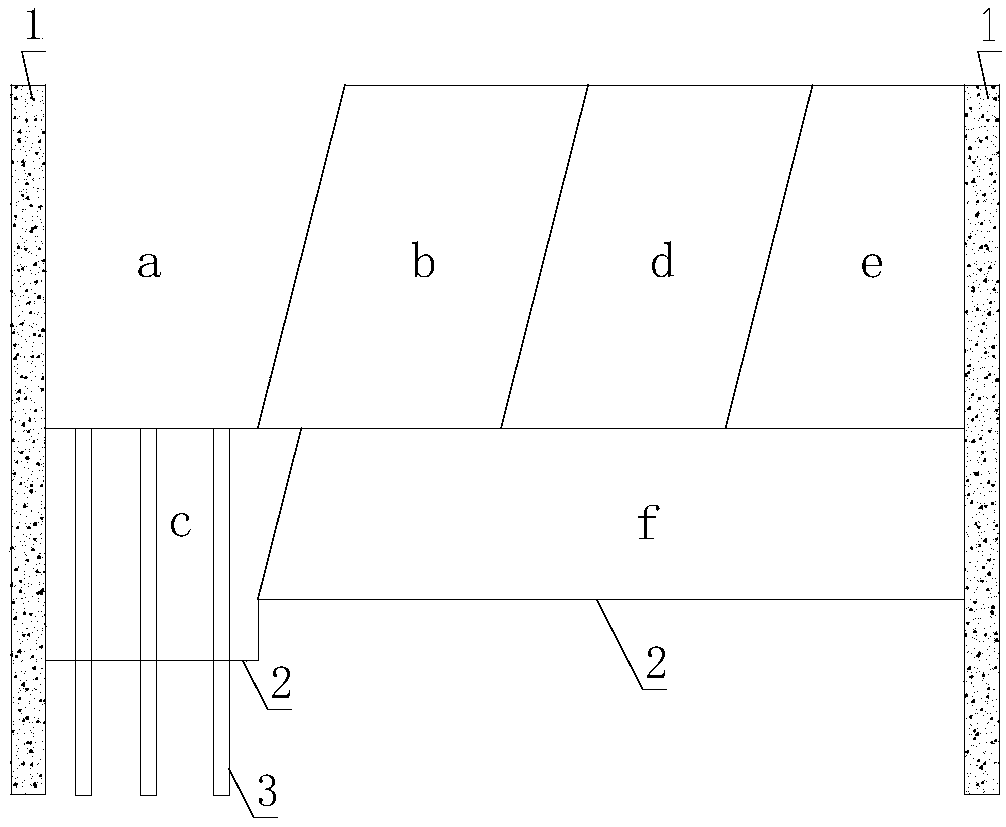

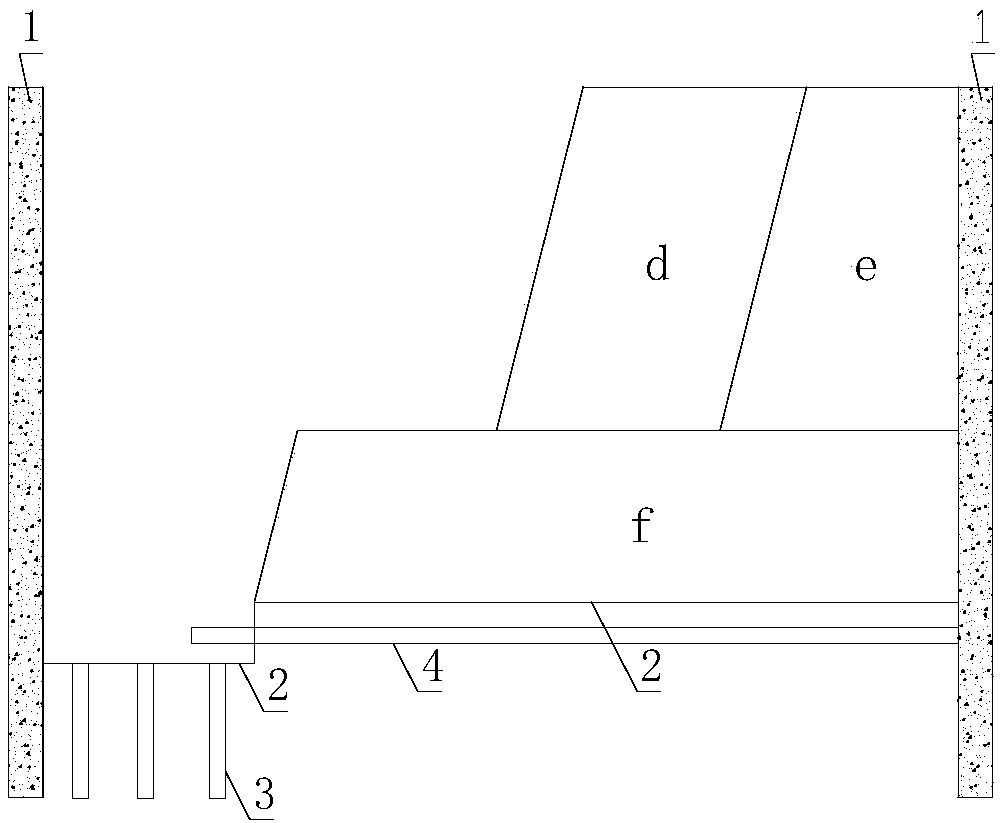

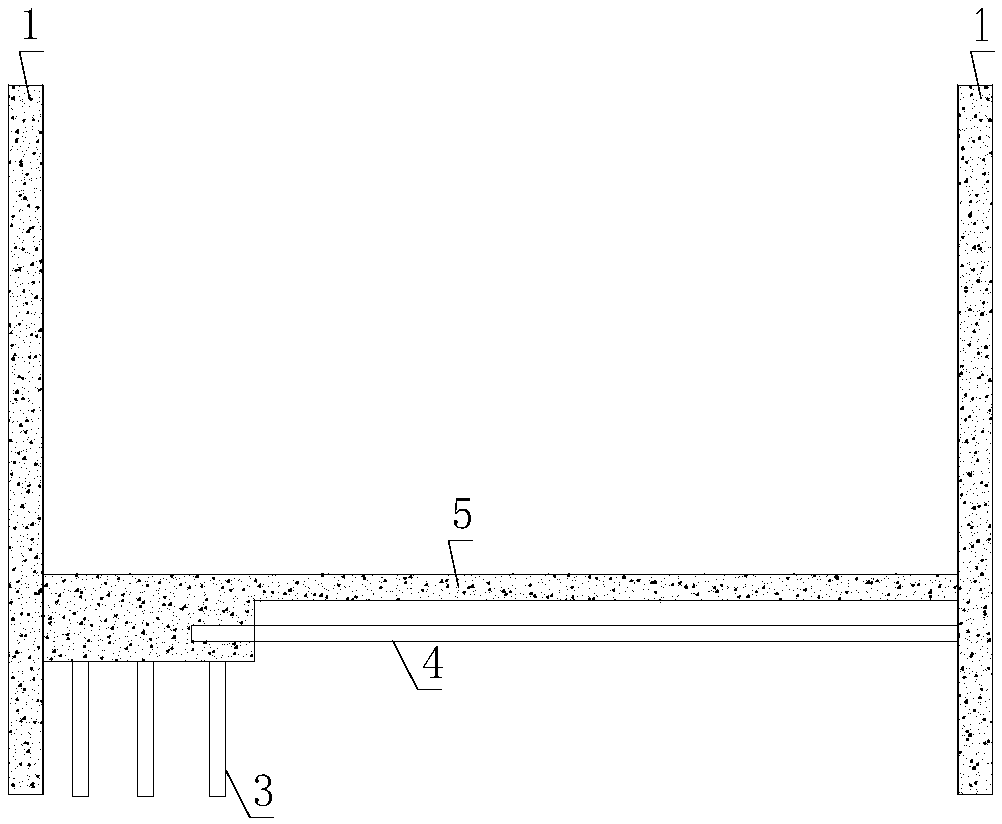

[0022] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples.

[0023] The invention is mainly composed of two structures: the frozen soil curtain formed by vertical-horizontal joint freezing, and the common underground continuous wall.

[0024] Before the excavation of the foundation pit, the underground diaphragm wall shall be constructed, and the force of the diaphragm wall shall be calculated according to the actual local geological conditions and the design scheme, and the reinforcement shall be reasonably provided.

[0025] Referring to accompanying drawing, a kind of construction method that is used for ultra-deep foundation pit combined freezing back cover comprises the steps:

[0026] S1, the construction of underground diaphragm wall 1, the verticality of each wall should be ensured during construction;

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com