Bathroom water stagnation zone assembly and construction method

A technology for toilets and hoses, applied in building components, building insulation materials, buildings, etc., can solve problems such as water overflow at the threshold, and achieve the effect of strengthening the effect of maintaining dryness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

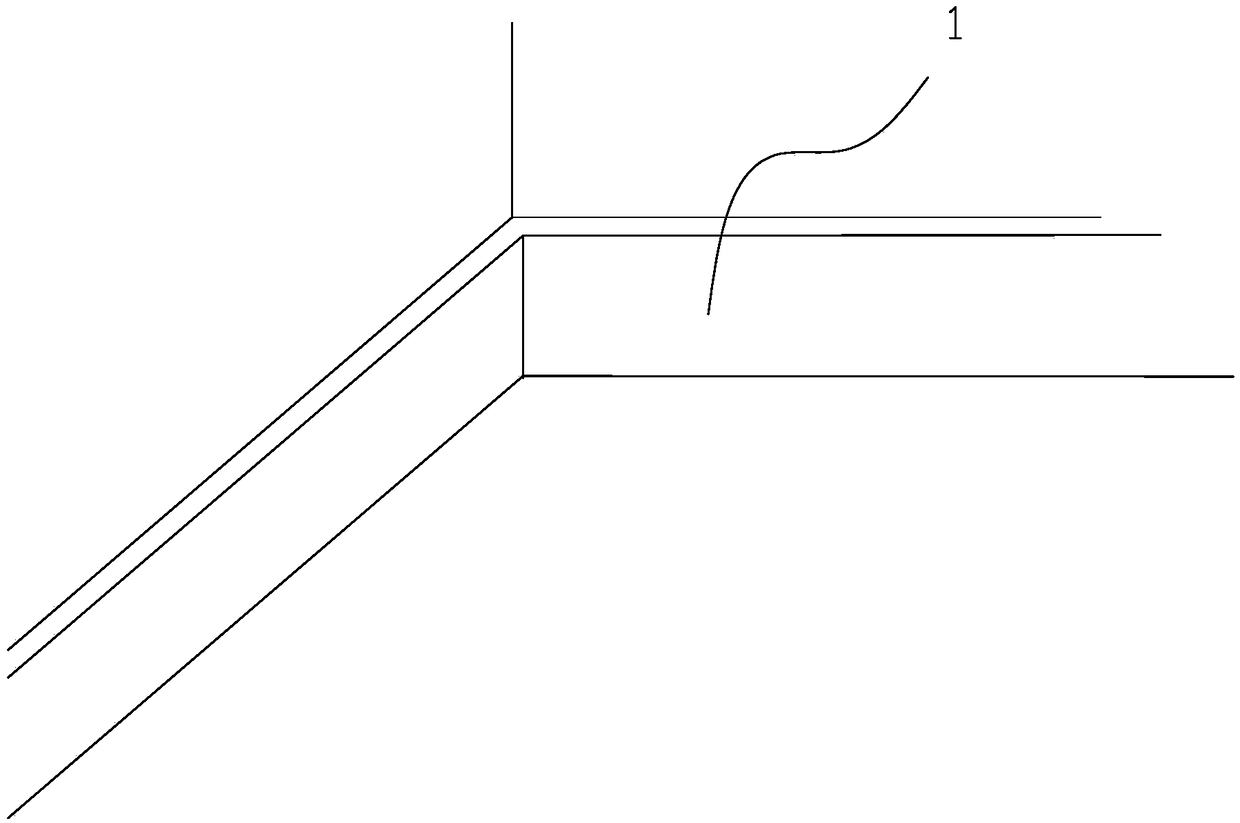

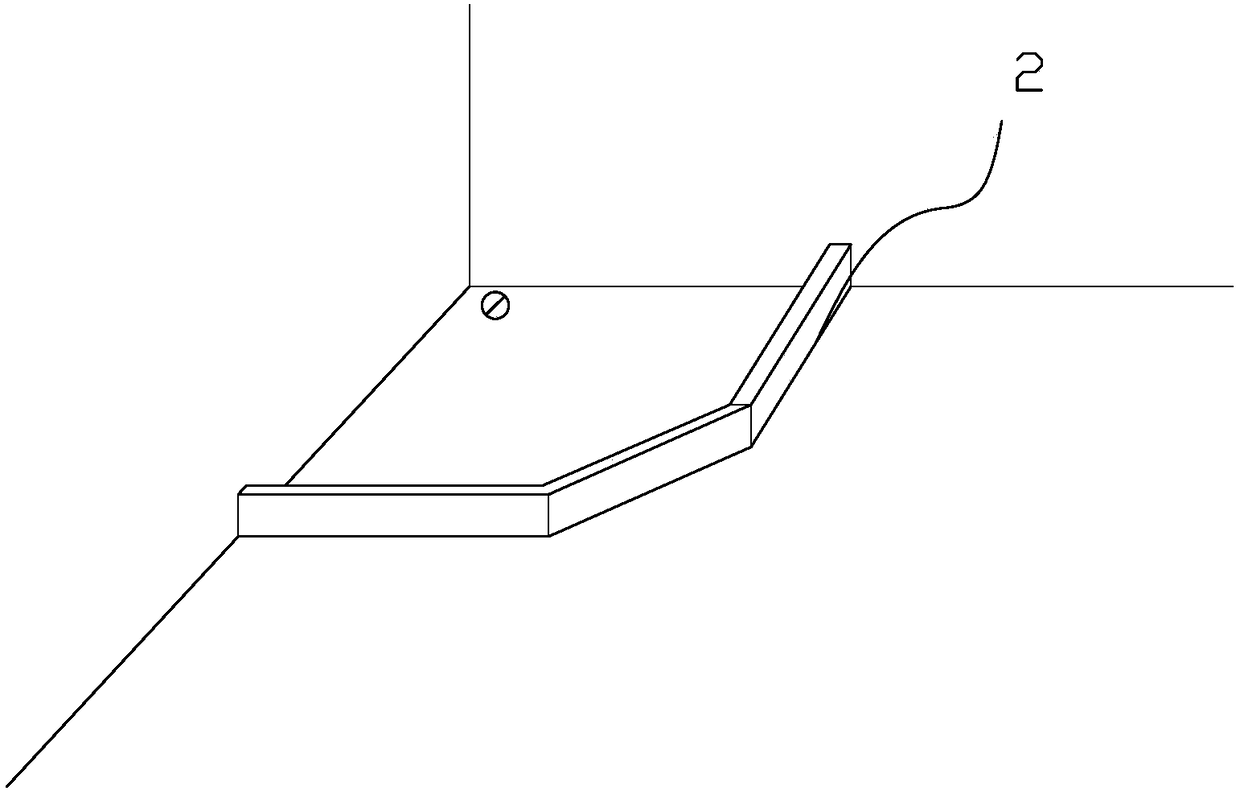

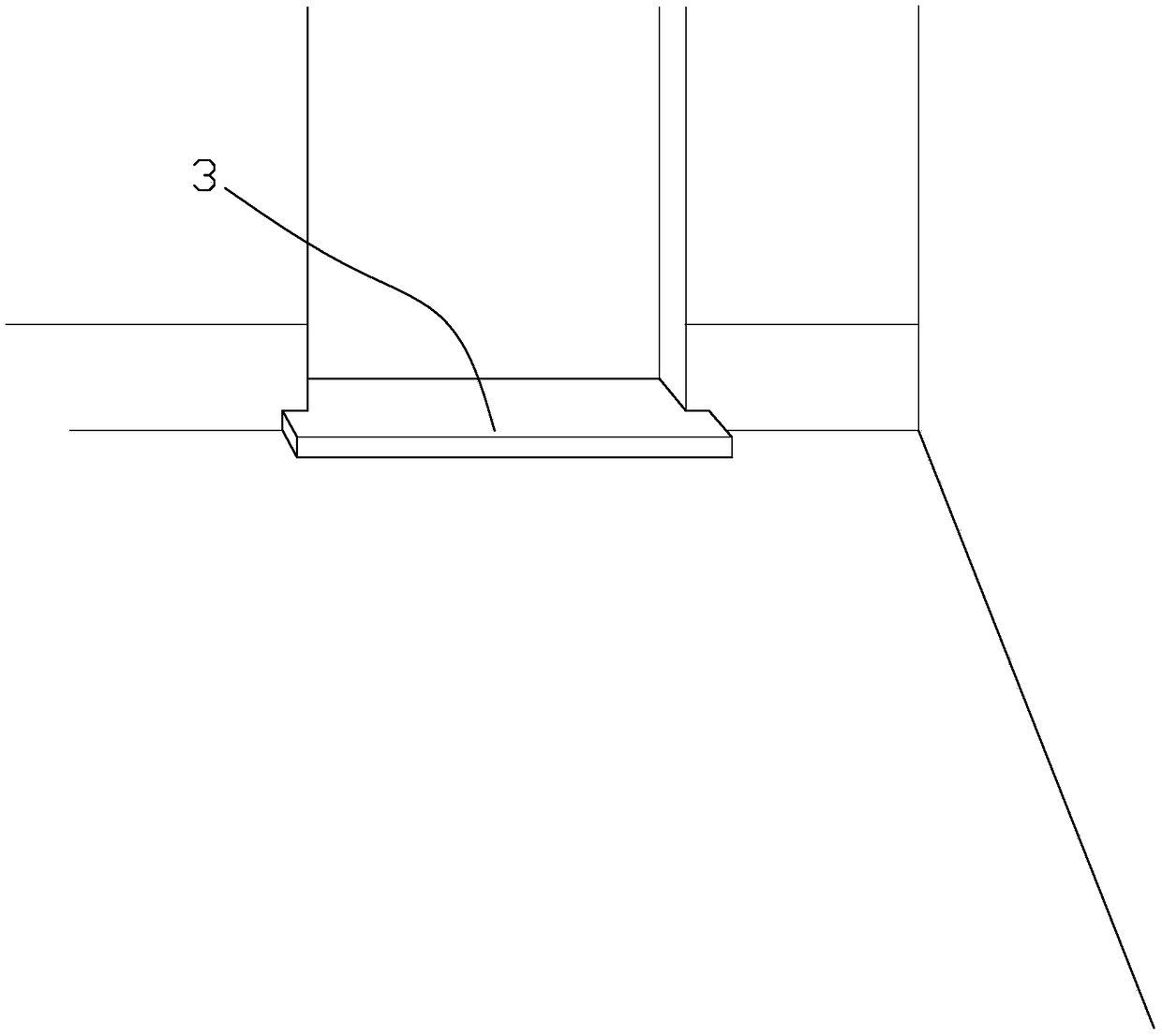

[0016] The water retaining assembly of the present invention includes a water retaining beam 1, a shower bar 2 and a bathroom threshold 3, the slump of the water retaining beam is 6-8mm, and the shower bar includes the inner and outer parts of the water retaining bar. Surrounding, the inner part of the water retaining strip is integrated with the ground, and a distance of 0.5cm is left as the connection between the outer surround and the inner part of the water retaining strip; 0.5-0.8cm is reserved outside the threshold of the bathroom as a stone bonding layer

Embodiment 2

[0018] The present invention also provides the construction method of the stagnant water belt assembly, which comprises the following steps:

[0019] 101 Fabrication of water-retaining beams: Formwork is set up at the wall and ground in the wet area according to the shape of the water-retaining beams. The water-retaining beams are strip beams connected to the bottom of the wall. According to the formwork, the water-retaining beam is also made at the same time. The water-retaining beam requires the concrete label to be C20 and the slump to be 6-8mm to ensure the stress of the concrete;

[0020] 102 After the ground is poured and tamped, make shower water-retaining strips: use cement mortar with a ratio of cement and mortar of 1:2.5 to make the inner part of the water-retaining strip, and then roll it to connect with the ground, so that the inner part of the water-retaining strip and the ground become a whole , and leave a distance of 0.5cm as the connection between the outer en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com